Workpiece machining tool

A machining and workpiece technology, applied in the field of machining tooling of workpieces, can solve the problems of difficult to ensure the dimensional accuracy of workpieces, prone to vibration knives, spring knives, and less force support of end plates, and reduce the clamping and correction time. Fast installation speed and stable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

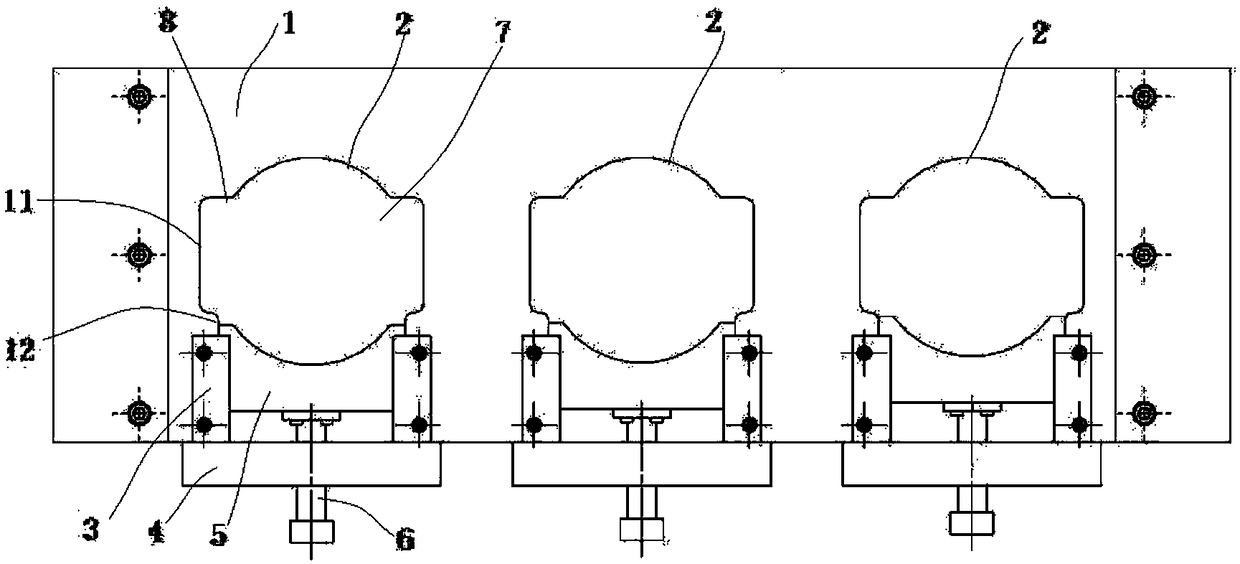

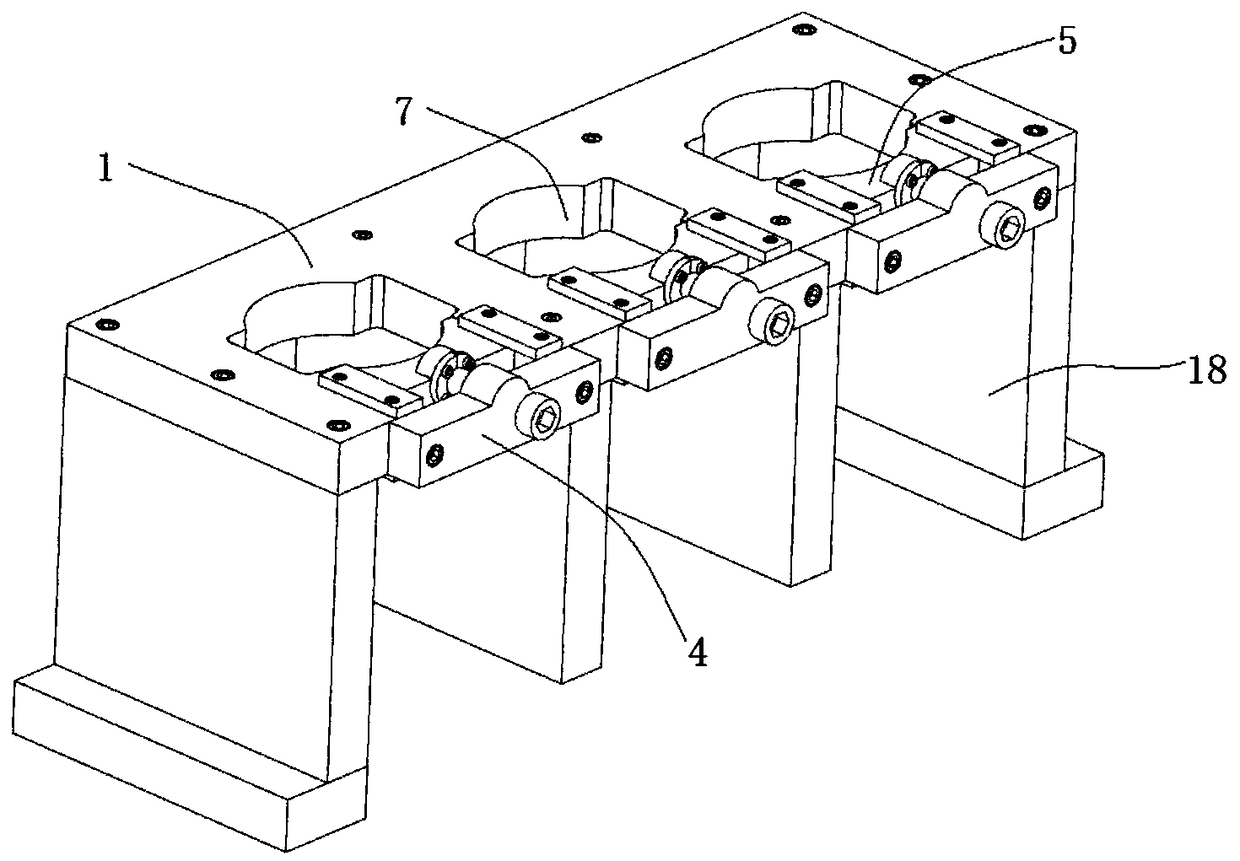

[0018] as attached figure 2 And attached image 3 As shown, a machining tool for a workpiece includes a base plate 1, the base plate 1 is a rectangular plate body, and a number of support plates 18 are arranged at the bottom of the base plate for supporting the base plate 1, and the base plate 1 includes at least one processing station 2. Each processing station correspondingly clamps a workpiece to be processed. The processing station 2 includes a clamping plate 5 and a driving mechanism 6. The clamping plate is a plate structure. The upper and lower parts of the substrate 1 are provided with The installation groove 7, one side of the installation groove 7 is an opening, the installation groove 7 is a U-shaped semi-closed structure, and the side wall opening in a length direction of the substrate 1 forms the opening side of the installation groove 7, so The opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com