A mid-point voltage balancing method for a three-level full-bridge DC conversion device

A technology of DC conversion and DC input voltage, which is applied in the direction of converting DC power input to DC power output, output power conversion device, and adjusting electric variables, etc., which can solve the problem of high screening cost and workload, high cost of drive circuit transformation, and component failure. Consistency requirements are very high, to achieve the effect of easy implementation, reducing voltage stress, and ensuring voltage equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

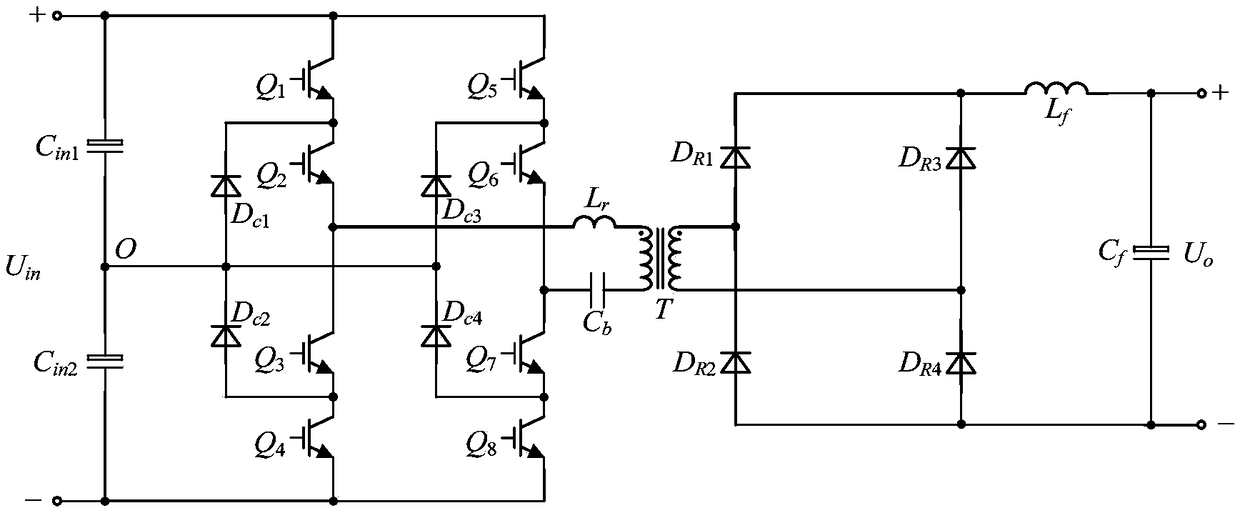

[0034] figure 1 It is the main circuit diagram of the non-flying capacitor type three-level full-bridge DC conversion device used for control by the method of the present invention. Such as figure 1 As shown, the flying capacitor is canceled in this circuit, mainly including: the first input voltage dividing capacitor C in1 and a second input divider capacitor C in2 ; The first switching tube Q 1 , the second switching tube Q 2 , the third switching tube Q 3 , the fourth switching tube Q 4 , the fifth switching tube Q 5 , the sixth switching tube Q 6 , the seventh switching tube Q 7 and the eighth switching tube Q 8 ; The first rectifier diode D R1 , the second rectifier diode D R2 , the third rectifier diode D R3 , the fourth rectifier diode D R4 ; The first clamping diode D c1 , the second clamping diode D c2 , the third clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com