Copper alloy fine wire for ball bonding

A technology of copper alloy and thin wire, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the unsolved problems of tail wire bending, front end bending of wire rods, and unstable mechanical properties of thin bonding wires, etc., and achieve delayed copper alloy thin wires. Effects of oxidation, spark discharge stabilization, and uniform melting of solder balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

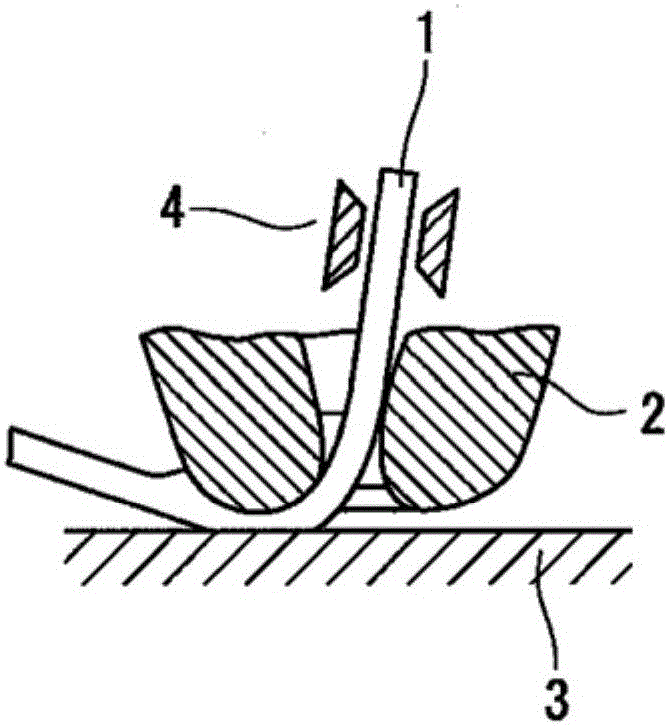

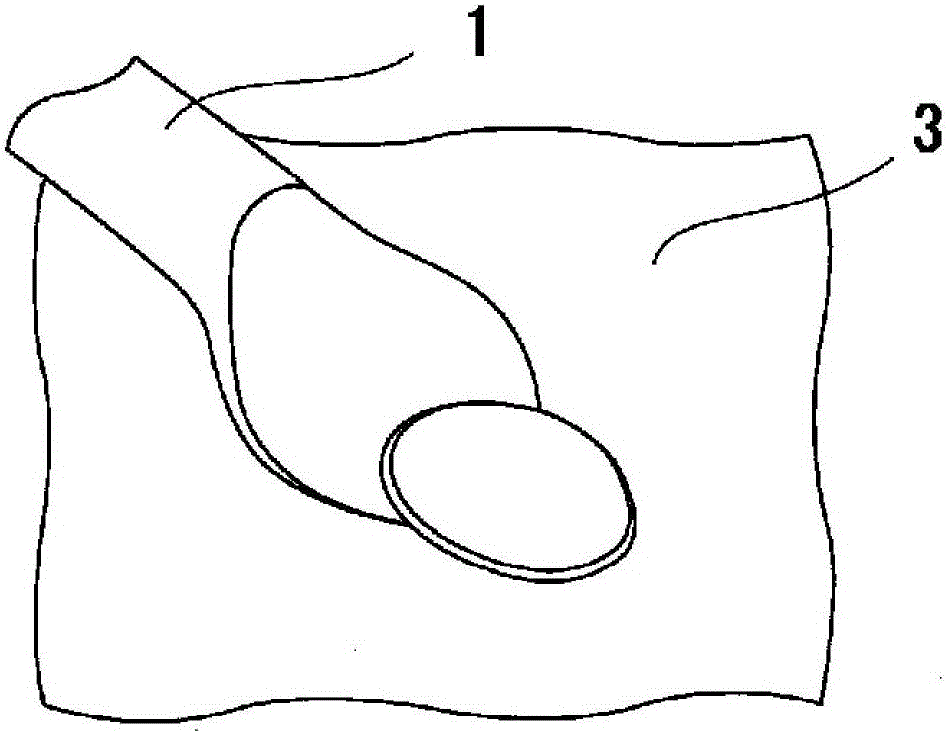

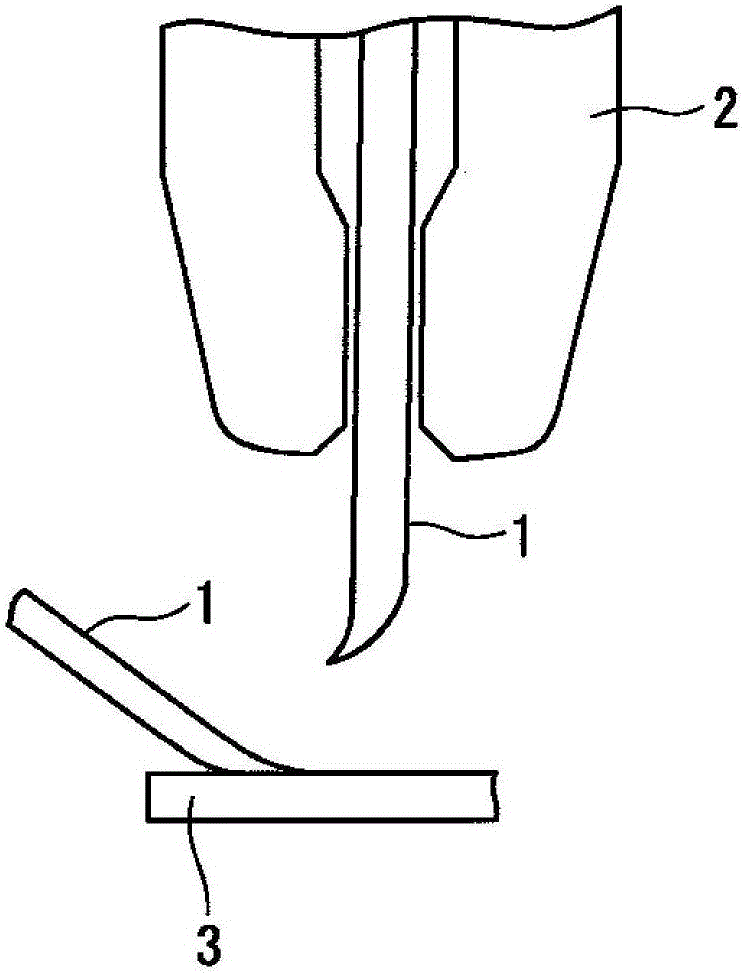

Image

Examples

Embodiment

[0069] The core material uses copper (Cu) with a purity of 99.9998% by mass (5N), and phosphorus (P) and nickel (Ni), palladium (Pd), platinum (Pt), gold (Au) and silver (Ag) as an added element. As the base metal element, an element generally contained in high-purity copper is selected. That is, bismuth (Bi), selenium (Se), tellurium (Te), zinc (Zn), iron (Fe), nickel (Ni), and tin (Sn) are appropriately selected. These metals will be blended within a predetermined range as Example 1-Example 23. The details are shown in Table 1.

[0070] Next, this was subjected to continuous casting, and then the first wire drawing was performed to obtain a thick wire (diameter: 1.0 mm) before being covered with a stretching material. Next, intermediate heat treatment (400 degreeC x 4 hours) was performed. Afterwards, a noble metal coating layer formed by a gold (Au) thin extension layer and a palladium (Pd) extension layer is provided as required. The semi-finished wires were continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com