Sodium alginate nanofiber as well as large-scale electrospinning preparation method and application thereof

A sodium alginate and nanofiber technology, applied in the field of micro-nano materials, can solve the problems of difficult formation of fiber structure, low content of sodium alginate, and inability to form continuous jets, etc., and meet the requirements of isolating foreign objects and bacteria and spinning conditions Low, suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A large-scale electrospinning preparation method of sodium alginate nanofibers, comprising the following steps:

[0029] (1) Preparation of spinning precursor solution: Dissolve sodium alginate powder (viscosity 500cps) and polyvinylpyrrolidone PVP (relative molecular mass 40,000) in water, then place it on a magnetic stirrer and stir until a homogeneous spinning precursor is formed Liquid, wherein, the content of sodium alginate is 0.5% (wt%), and the mass ratio of polyvinylpyrrolidone and sodium alginate is 1:20;

[0030] (2) Preparation of nanofibers by air-assisted electrospinning: the spinning precursor solution prepared in step (1) is added to the feeding cylinder of the electrospinning device, and the electrospinning device includes a high-voltage power supply, a spinning tube connected to the positive electrode of the high-voltage power supply The silk nozzle, the feeding cylinder connected to the spinning nozzle, and the air pump. The air outlet of the air pump...

Embodiment 2

[0032] A large-scale electrospinning preparation method of sodium alginate nanofibers, comprising the following steps:

[0033] (1) Preparation of spinning precursor solution: Dissolve sodium alginate powder (viscosity 300cps) and polyvinyl alcohol PVA (relative molecular mass 105000) in deionized water and heat in a water bath at 80°C, then place it on a magnetic stirrer and stir until Form a homogeneous spinning precursor solution, wherein the content of sodium alginate is 15% (wt%), and the mass ratio of polyvinyl alcohol to sodium alginate is 1:3;

[0034] (2) Preparation of nanofibers by air-assisted electrospinning: the spinning precursor solution prepared in step (1) is added to the feeding cylinder of the electrospinning device, and the electrospinning device includes a high-voltage power supply, a spinning tube connected to the positive electrode of the high-voltage power supply The silk nozzle, the feeding cylinder connected to the spinning nozzle, the injection pump...

Embodiment 3

[0036] A large-scale electrospinning preparation method of sodium alginate nanofibers, comprising the following steps:

[0037] (1) Preparation of spinning precursor solution: Dissolve sodium alginate powder (viscosity 400cps) and polyethylene oxide PEO (relative molecular mass 5,000,000) in water, then place it on a magnetic stirrer and stir until a homogeneous spinning precursor is formed Liquid, wherein, the content of sodium alginate is 9% (wt%), and the mass ratio of polyoxyethylene and sodium alginate is 1:25;

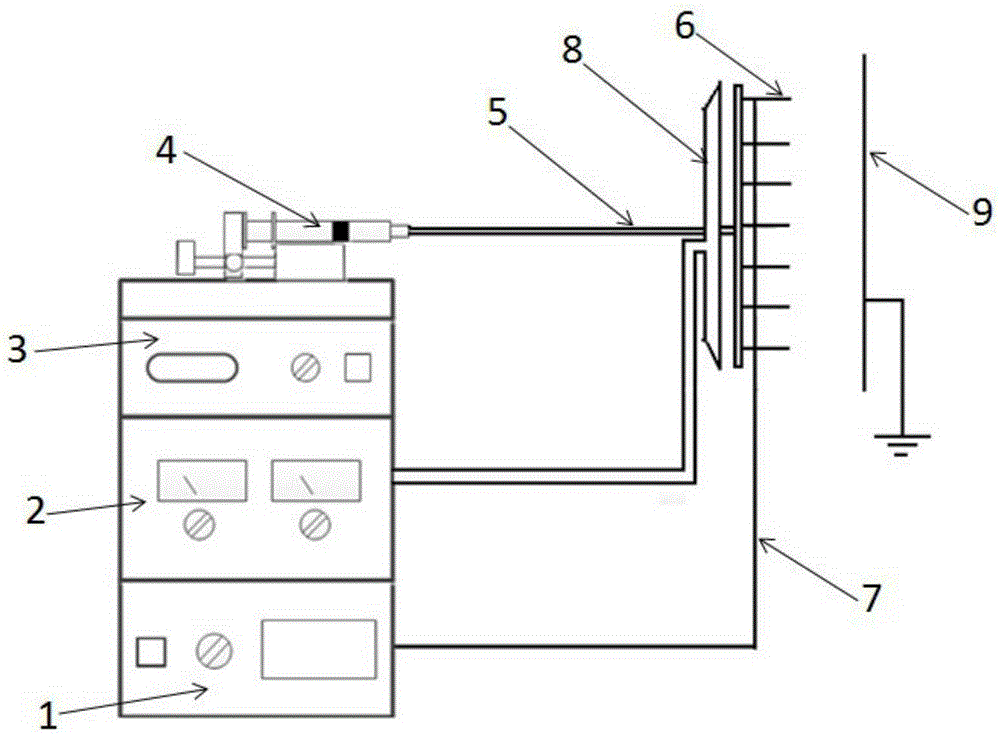

[0038] (2) Preparation of nanofibers by air-assisted electrospinning: the spinning precursor solution prepared in step (1) is added to the feeding cylinder of the electrospinning device, and the electrospinning device is a multi-nozzle air-assisted electrospinning device. Structural diagram such as figure 1 As shown, the device includes a high-voltage power supply 1, seven spinning nozzles 6 connected to the positive pole of the high-voltage power supply 1 throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com