Cross-linkable polymer linear colloid system for shale gas fracturing and preparation method thereof

A technology of polymer and linear glue, which is applied in the field of cross-linkable polymer linear glue system and its preparation for shale gas fracturing, which can solve the problems of poor effect of linear glue base liquid and achieve high viscosity and good application prospects , Suspended sand washing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Next, the preparation method of the above-mentioned cross-linkable polymer linear glue system for shale gas fracturing will be described in detail. It includes the step of preparing the base liquid and the step of mixing, wherein the step of preparing the base liquid is: take the flowback liquid of the formula amount, add the thickener and stir until dissolved, then add the clay stabilizer and the drainage aid of the formula amount, mix After uniformity, the base liquid is prepared and set aside; the mixing step is as follows: during the fracturing operation, pump the cross-linking agent of the formulated amount into the mixing tank of the sand mixer truck and add it to the base liquid to obtain a polymer linear glue cross-linking system.

[0037] According to one embodiment of the present invention, in parts by weight, add 982 to 989 parts of flowback liquid into the container and start stirring, then slowly add 3 to 5 parts of thickener into the flowback liquid and sti...

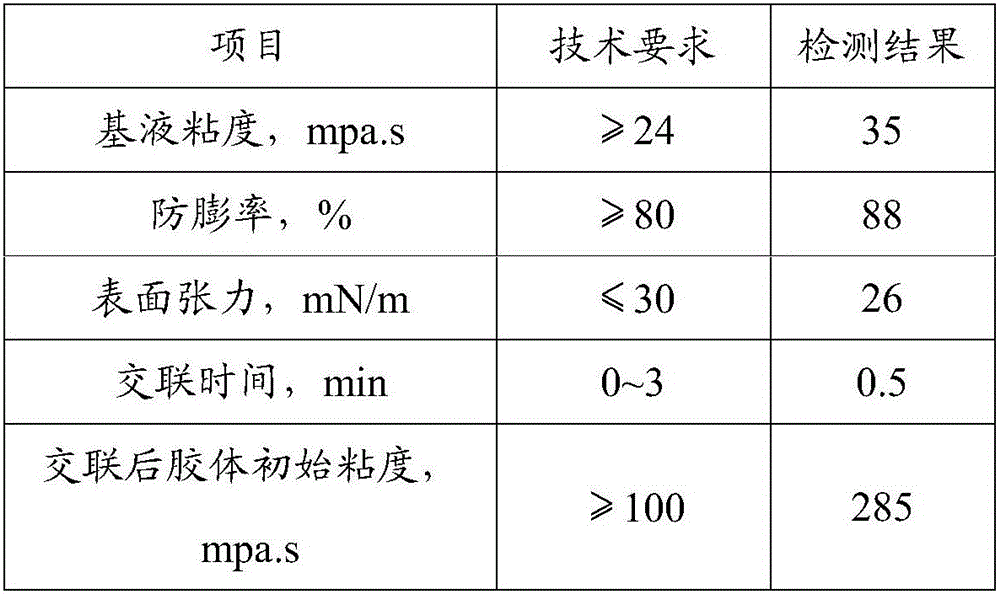

Embodiment 1

[0043] Under nitrogen protection and at a temperature of 15°C, in parts by weight, 30 parts of acrylamide was dissolved in 50 parts of deionized water, and 10 parts of 2-acrylamide-2-methylpropanesulfonic acid was added under stirring conditions Slowly add the aqueous solution of potassium persulfate obtained by dissolving 0.01 part of potassium persulfate in 10 parts of deionized water while stirring, react for 4 hours to obtain the thickener aqueous solution after the completion of the dropwise addition for 30 minutes, and solidify and granulate the thickener aqueous solution Then get the thickener.

[0044] Add 10 parts of zirconium oxychloride and 5 parts of borax into 65 parts of water and stir until dissolved, then heat up to 65°C, and then add 20 parts of triethanolamine to react for 3 hours to obtain an organic boron-zirconium composite crosslinking agent.

[0045] Add 10 parts of polyquaternium and 10 parts of potassium chloride into 80 parts of water, and stir for 60...

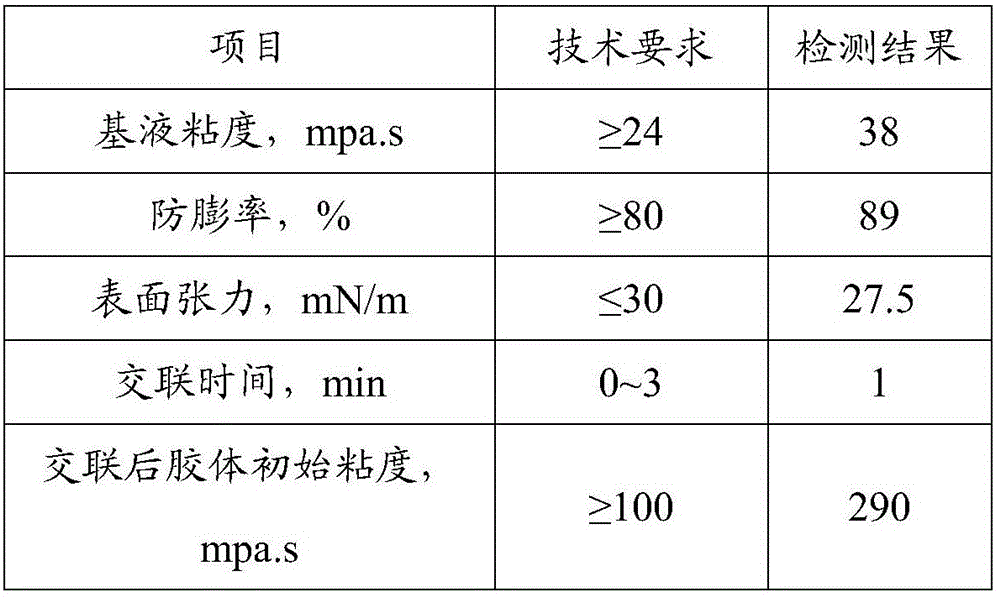

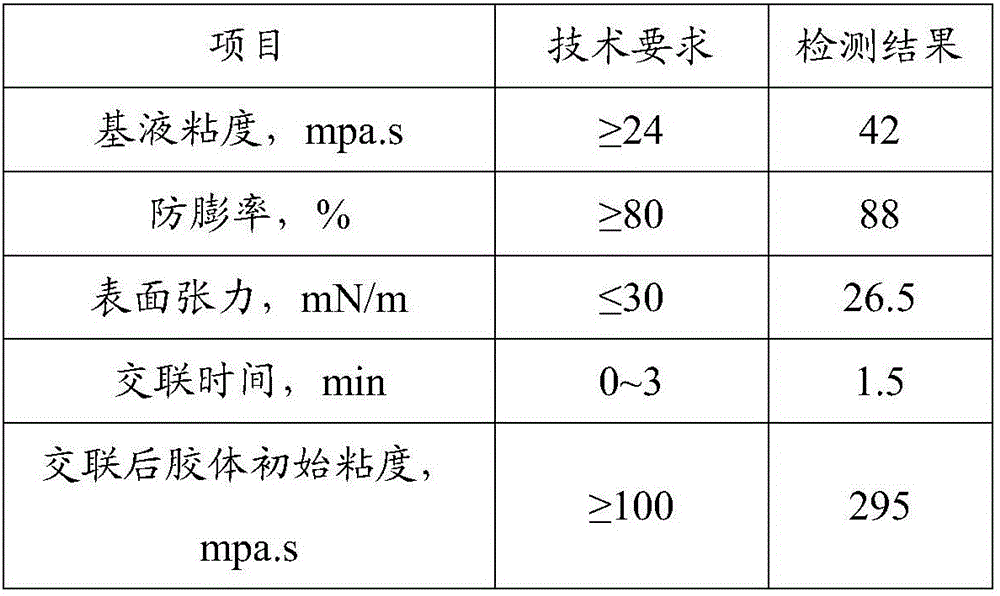

Embodiment 2

[0051] Under the protection of nitrogen and at a temperature of 18°C, in parts by weight, 40 parts of acrylamide was dissolved in 40 parts of deionized water, and 10 parts of acrylic acid was added under stirring conditions; while stirring, slowly dropwise added 0.015 parts of over The aqueous solution of potassium persulfate obtained by dissolving potassium sulfate in 10 parts of deionized water was added dropwise for 30 minutes and reacted for 4 hours to obtain a thickener aqueous solution, which was solidified and granulated to obtain a thickener.

[0052] Add 12 parts of zirconium oxychloride and 8 parts of borax into 60 parts of water and stir until dissolved, then heat up to 65°C, and add 20 parts of citric acid to react for 3 hours to obtain the organic boron-zirconium composite crosslinking agent.

[0053] Add 10 parts of polyquaternium and 10 parts of potassium chloride into 80 parts of water, and stir for 60 minutes to obtain a clay stabilizer.

[0054] Add 12 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com