Ultraviolet cured organic/inorganic hybrid super-hydrophilic coating and method for preparing same

An ultraviolet light and super-hydrophilic technology, applied in the field of super-hydrophilic materials, can solve problems such as intolerance to harsh conditions and poor mechanical properties, and achieve high production efficiency, good acid resistance and boiling water resistance, and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At room temperature, disperse 0.6g of 1,4‐dithiothreitol in 6g of tetrahydrofuran solvent and stir evenly, then add 3g of polyethylene glycol dimethacrylate (Mn=550) into the above solution , and then add 0.03g of triethylamine, react under nitrogen for 24h, add the product to ether and wash three times, and place the separated substance in a vacuum oven at 50°C for 12h to obtain a hydrophilic oligomer.

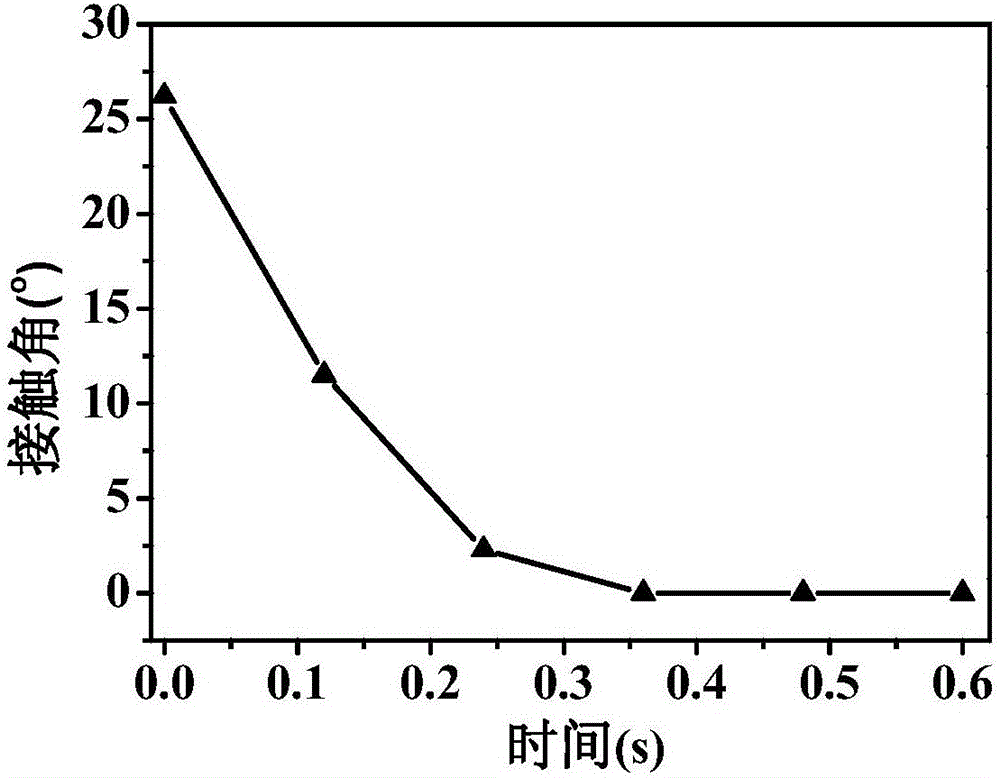

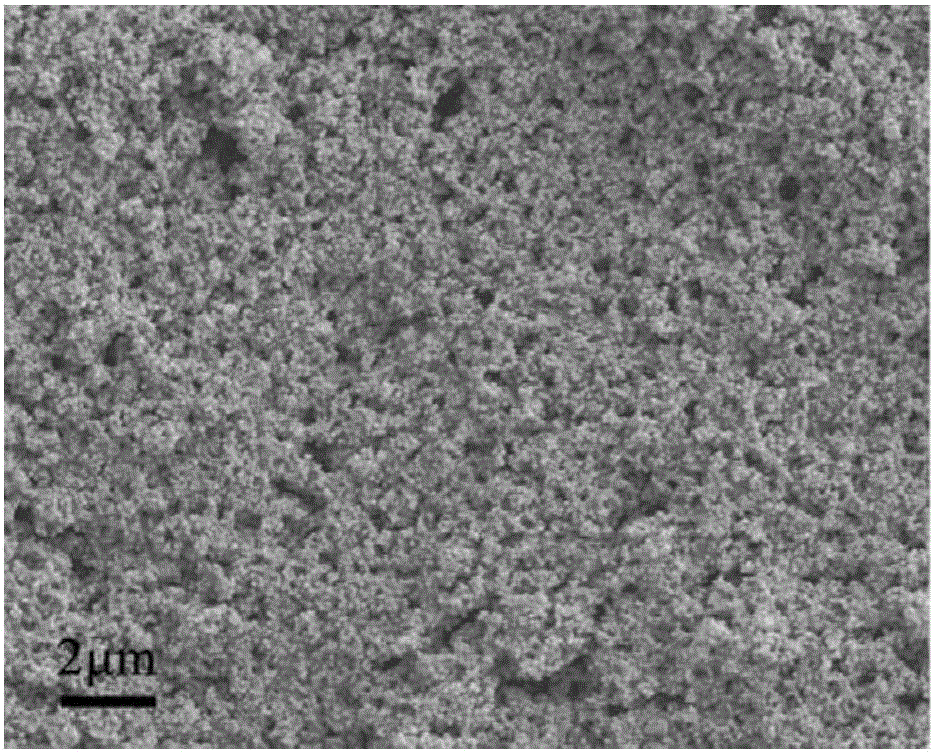

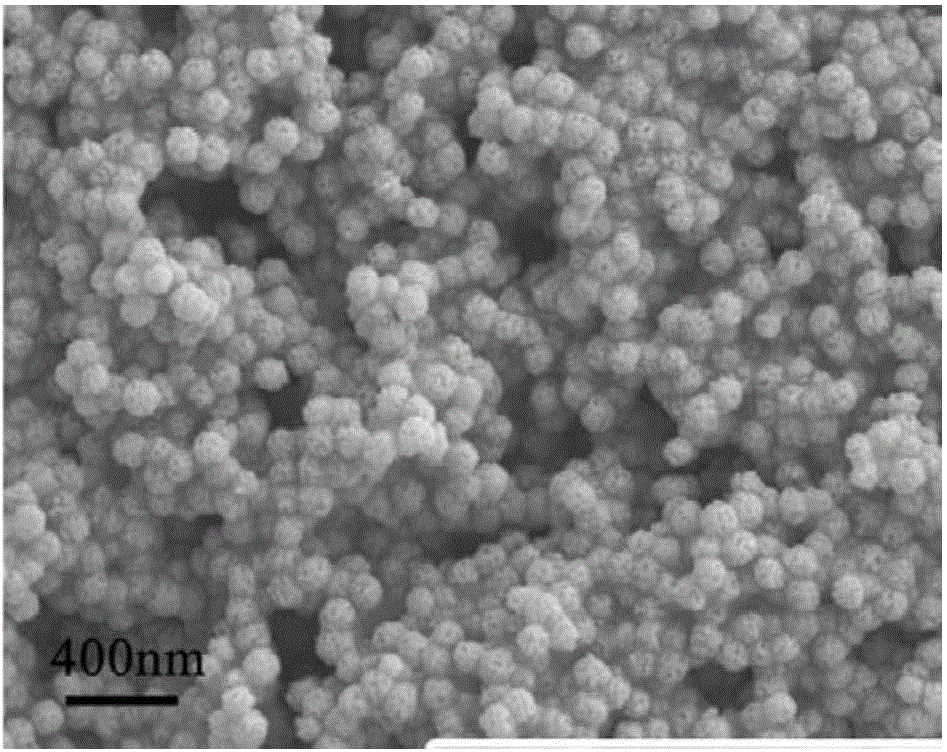

[0030] At room temperature, 0.4 g of mesoporous silica (Nanjing Xianfeng Nano Material Technology Co., Ltd.) with a particle size of 40 nm and a pore size of 2 nm was added to 4 g of methanol solvent, ultrasonically dispersed for 15 min, and 0.6 g of hydrophilic oligomers and mix evenly; then add 0.08g of pentaerythritol triacrylate and 0.02g of 2-hydroxy-2-methyl-1-phenyl-1-acetone (1173), stir and mix to form a uniform solution, using spray The method is to uniformly coat it on the glass surface, and the radiation intensity is 30mW / cm 2 UV light was irradiated for 6...

Embodiment 2

[0037] At room temperature, disperse 0.8g of 1,3-propanedithiol in 6g of tetrahydrofuran solvent and stir evenly, then add 1.8g of neopentyl glycol diacrylate to the above solution, and then add 0.09g of n- Butylamine was reacted under nitrogen for 8 hours, the product was added to ether and washed three times, and the separated substance was placed in a vacuum oven at 30°C for 36 hours to obtain a hydrophilic oligomer.

[0038] At room temperature, add 1.2 g of mesoporous silica with a particle size of 100 nm and a pore size of 10 nm into 4 g of methanol solvent, ultrasonically disperse for 15 min, then add 1.2 g of the oligomer prepared above, and mix well; Add 0.8g of pentaerythritol tetraacrylate and 0.06g of 1‐hydroxycyclohexyl phenyl ketone (184), stir and mix to form a homogeneous solution, which is evenly coated on the surface of the stainless steel sheet by spraying (in order to make the stainless steel The iron sheet will not be corroded during the acid resistance te...

Embodiment 3

[0041] At room temperature, disperse 0.85g of 1,6-hexanedithiol in 6g of tetrahydrofuran solvent and stir evenly, then add 1.3g of 1,5-pentanediol diacrylate to the above solution, and then add 0.05 g of N,N-dimethylcyclohexylamine, reacted under nitrogen for 24 hours, added the product to ether and washed three times, and placed the separated substance in a vacuum oven at 35°C for 24 hours to obtain a hydrophilic oligomer.

[0042] At room temperature, 0.75 g of mesoporous silica with a particle size of 60 nm and a pore size of 5 nm was added to 4 g of methanol solvent, ultrasonically dispersed for 15 min, and then 1.1 g of the above-prepared hydrophilic oligomer was added, and Mix well; add 0.08 g of trimethylolpropane trimethacrylate and 0.05 g of 2‐methyl‐1‐(4‐methylthiophenyl)‐2‐morpholine‐1‐acetone (907) , stirred and mixed to form a uniform solution, which was evenly coated on the surface of the ceramic sheet by spraying (in order to prevent the ceramic sheet from being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com