Pure water gravure printing ink for printing PVC decorative film and preparation method thereof

A pure water type, printing blue technology, applied in inks, applications, household appliances, etc., can solve the problems of inability to achieve decoration and protection, low drying rate of water-based inks, harm to human health, etc., to achieve stable color, clear printing patterns, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

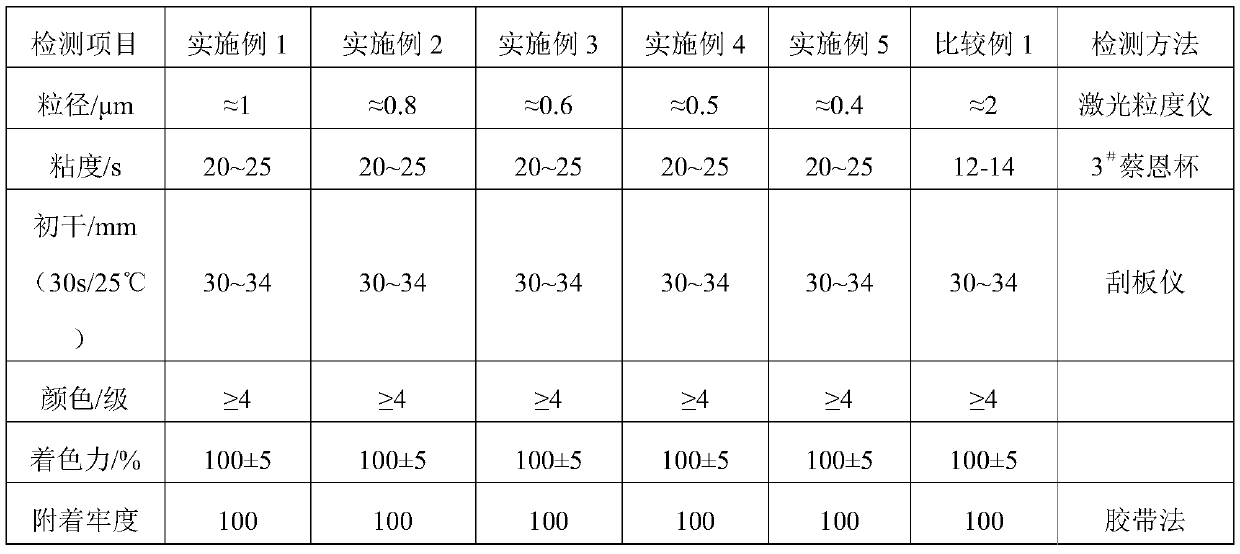

Examples

Embodiment 1

[0036] The preparation method of the pure water type gravure ink for printing PVC decorative film is as follows:

[0037] 1) Weigh each raw material according to the following quality: cyan pigment 5kg, water-based PVC glue 50kg, water-based polyurethane resin 20kg, water-based epoxy resin 10kg, deionized water 15kg, acetylene glycol ethoxylate 1kg, pigment affinity group Copolymer aqueous solution (concentration is 40wt%) 1kg, polysiloxane-polyether copolymer 1kg;

[0038] 2) Weigh the above components and pour them into the mixing device, stir them with a mechanical mixer for 40 minutes, then use a sand mill to disperse them, and grind them until the particle size is below 1 μm. If the particle size does not meet the standard, you need to continue grinding, and finally test the ink The various indicators and performance of the product are filtered and packaged after reaching the standard to obtain the finished product.

Embodiment 2

[0040] The preparation method of the pure water type gravure ink for printing PVC decorative film is as follows:

[0041] 1) Weigh each raw material according to the following quality: cyan pigment 20kg, water-based PVC glue (Shanghai Ruitu Chemical Co., Ltd.) 75kg, water-based polyurethane resin 20kg, water-based epoxy resin 10kg, deionized water 20kg, acetylene glycol ethoxylate 1.5kg, 1.5kg of aqueous solution of copolymer containing pigment affinity groups (concentration is 40wt%), 1.2kg of polysiloxane-polyether copolymer;

[0042] 2) Weigh the above components and pour them into the stirring device, stir with a mechanical mixer at a speed of 800rpm for 45 minutes, and then use a sand mill to disperse them. The working pressure of the diaphragm pump is 0.25MPa. If the particle size is below 0.8μm, if the particle size does not meet the standard, it needs to continue grinding, and finally test the various indicators and performance of the ink. After reaching the standard, ...

Embodiment 3

[0044] The preparation method of the pure water type gravure ink for printing PVC decorative film is as follows:

[0045] 1) Weigh each raw material according to the following quality: cyan pigment 8kg, water-based PVC glue (Shanghai Ruitu Chemical Co., Ltd.) 70kg, water-based polyurethane resin 28kg, water-based epoxy resin 25kg, deionized water 20kg, acetylene glycol ethoxylate 1.8kg, 1.8kg of aqueous solution of copolymer containing pigment affinity groups (concentration is 40wt%), 1.4kg of polysiloxane-polyether copolymer;

[0046] 2) Weigh the above components and pour them into the stirring device, stir with a mechanical mixer at 700rpm for 60 minutes, and then sand and disperse them with a sand mill. The working pressure of the diaphragm pump is 0.30MPa. The diameter is between 0.5-0.8 μm. If the particle size does not meet the standard, it needs to continue grinding. Finally, the various indicators and performance of the ink are tested. After reaching the standard, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com