High-heat-conduction flame-retardant heat rectification material, and preparation method and application thereof

A flame-retardant, thermal rectification technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of low thermal conductivity, poor mechanical properties, flammability of organic materials, etc., and achieve high thermal conductivity and heat absorption capacity. Strong and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

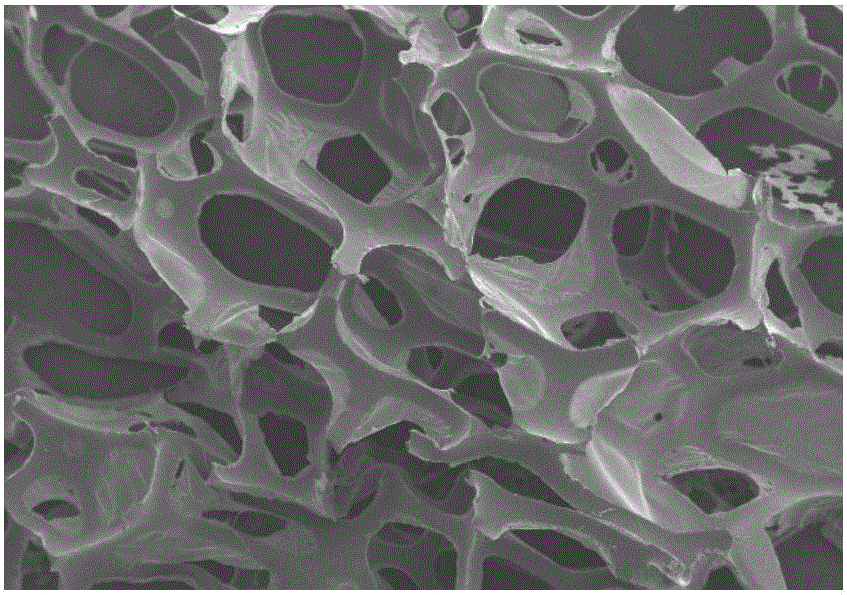

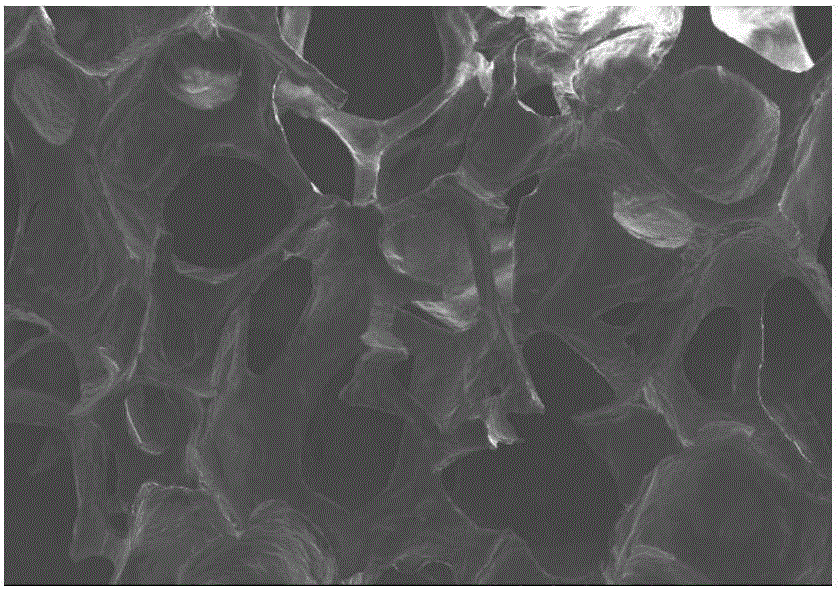

Image

Examples

Embodiment 1

[0040] (1) Take 34.2g modified paraffin, 30.66g modified fatty acid, 0.3g lauryl polyoxyethylene ether, 0.3g palmityl alcohol polyoxyethylene ether, 0.3g stearyl polyoxyethylene ether, 0.4g magnesium oxide, 0.3g magnesium hydroxide, 0.4g silicon carbide, 7.2g expandable graphite, 0.69g alumina, 2.6g modified expanded graphite, 1.3g worm powder, 2.5g carbon sponge, 0.34g polyurethane curing agent, 0.31g acrylic resin, 0.3g silane coupling agent KH570, 4.9g high-density polyethylene, 3.8g polypropylene, 9.2g SEBS;

[0041] (2) heating the modified paraffin and the modified fatty acid to 70° C. to melt, adding lauryl alcohol polyoxyethylene ether, palmityl alcohol polyoxyethylene ether, and stearyl polyoxyethylene ether to thicken it; then adding magnesium oxide, Stir for 15 minutes, add magnesium hydroxide, stir for 3 minutes, add silicon carbide and expandable graphite, stir for 13 minutes, finally add alumina, stir for 9 minutes, and obtain a mixed system with good dispersibil...

Embodiment 2

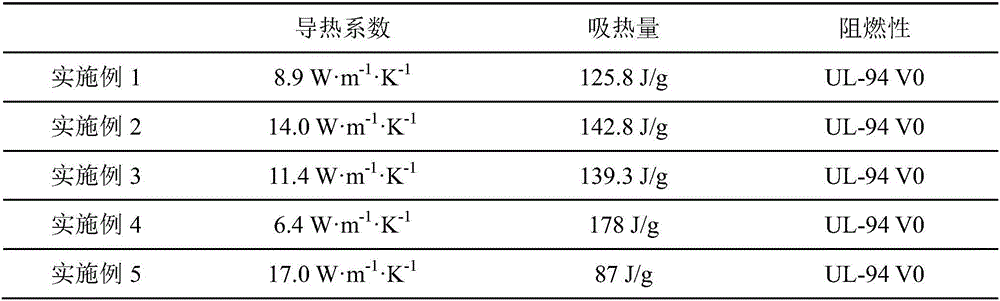

[0047] Reference Example 1 to prepare high thermal conductivity flame retardant heat rectification material, the difference is that the composition ratio of step (1) rectification material is: 39.9g modified paraffin, 32.4g modified fatty acid, 0.1g lauryl polyoxyethylene ether, 0.1 g palmityl alcohol polyoxyethylene ether, 0.1g stearyl polyoxyethylene ether, 0.2g magnesium oxide, 0.1g magnesium hydroxide, 0.2g silicon carbide, 0.9g expandable graphite, 0.3g alumina, 7.5g modified expanded Graphite, 7.8g worm powder, 3.1g carbon sponge, 0.2g polyurethane curing agent, 0.2g acrylic resin, 0.1g silane coupling agent KH570, 5.1g high-density polyethylene, 0.9g polypropylene, 0.8g SEBS. The performance test results of the high thermal conductivity flame retardant heat rectification material are shown in Table 1.

Embodiment 3

[0049] Reference Example 1 was used to prepare a high thermal conductivity and flame-retardant heat rectification material. The difference is that the composition ratio of the rectification material in step (1) is: 41.9g modified paraffin, 27.7g modified fatty acid, 0.3g lauryl polyoxyethylene ether, 0.3 g palmityl alcohol polyoxyethylene ether, 0.3g stearyl polyoxyethylene ether, 0.2g magnesium oxide, 0.2g magnesium hydroxide, 0.2g silicon carbide, 4.9g expandable graphite, 0.3g alumina, 2.5g modified expanded Graphite, 2.8g worm powder, 2.1g carbon sponge, 0.2g polyurethane curing agent, 0.2g acrylic resin, 0.1g silane coupling agent KH570, 5.1g high-density polyethylene, 5.9g polypropylene, 4.8g SEBS. The performance test results of the high thermal conductivity flame retardant heat rectification material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com