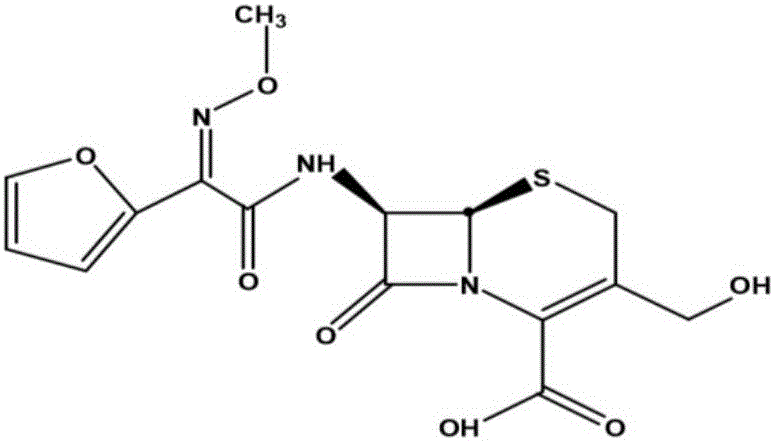

Preparation method of 3-deaminized formoxyl-cefuroxime acid crystal

A technology of cefuroxime acid and carbamoyl, which is applied in the field of preparation technology of 3-decarbamoyl-cefururoxime acid crystallization, which can solve problems such as filtration and drying difficulties, affecting product quality, and small particle size of the product, so as to shorten crystallization The effects of time, good fluidity, and low viscosity of crystal slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The 3-decarbamoyl-cefururoxime acid liquid prepared by the upstream synthesis process is used as raw material, wherein the content of 3-decarbamoyl-cefururoxime acid is 50 mg / mL, 280 mL is put into a 500 mL jacketed crystallizer, and the Circulating water bath keeps the temperature in the crystallizer at 2°C. Vacuumize the crystallizer with a vacuum pump to remove methylene chloride in the feed liquid. There are a lot of bubbles on the surface of the solution at the beginning, and stop degassing when there are no bubbles on the surface. Turn on stirring and adjust the rotation speed to 150r / min, slowly add dilute hydrochloric acid with a mass fraction of 10% to the crystallizer to adjust the pH value to 3.8, add 0.15g of treated seed crystals, change the stirring speed to 100r / min, and grow the crystal for 50min . Adjust the stirring to 110r / min, continue to slowly drop dilute hydrochloric acid into the crystallizer at a rate of 3mL / h to adjust the pH value to the end p...

Embodiment 2

[0030] The 3-decarbamoyl-cefururoxime acid liquid prepared by the upstream synthesis process is used as raw material, wherein the content of 3-decarbamoyl-cefururoxime acid is 50 mg / mL, 350 mL is put into a 500 mL jacketed crystallizer, and the Circulating water bath keeps the temperature in the crystallizer at 5°C. Use a vacuum pump to evacuate the crystallizer to remove methylene chloride in the feed liquid. There are a lot of bubbles on the surface of the solution at the beginning, and stop degassing when there are no bubbles on the surface. Turn on the stirring and adjust the rotation speed to 170r / min, slowly add dilute hydrochloric acid to the crystallizer to adjust the pH value to 3.7, add 0.15g of treated seed crystals, change the stirring speed to 100r / min, and grow the crystal for 45min. Adjust the stirring to 110r / min, continue to slowly drop dilute hydrochloric acid into the crystallizer at a rate of 4mL / h to adjust the pH value to the end point of 1.9, and grow the...

Embodiment 3

[0032] The 3-decarbamoyl-cefururoxime acid liquid prepared by the upstream synthesis process is used as raw material, wherein the content of 3-decarbamoyl-cefururoxime acid is 50 mg / mL, 350 mL is put into a 500 mL jacketed crystallizer, and the A circulating water bath kept the temperature inside the crystallizer at 4°C. Turn on the stirring and adjust the rotation speed to 160r / min, slowly add dilute hydrochloric acid to the crystallizer to adjust the pH value to 3.9, add 0.4g of the treated seed crystal, change the stirring speed to 100r / min, and grow the crystal for 45min. Adjust the stirring to 110r / min, continue to slowly drop dilute hydrochloric acid into the crystallizer at a rate of 3.9mL / h to adjust the pH value to the end point of 2.0, and grow crystals for 30min. Wash after filtering, soak and wash the crystals with 20mL of dichloromethane for 1min, filter; soak and wash the crystals with 120mL of cold purified water for 3 times, soak for 1min each time, and filter;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com