Culture method of photosynthetic microorganisms and photobioreactor

A photobioreactor, photosynthetic microorganism technology, applied in photobioreactors, microorganism-based methods, methods of supporting/immobilizing microorganisms, etc. To solve the problem of high consumption, to achieve the effect of improving space utilization efficiency, significant specific surface area, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

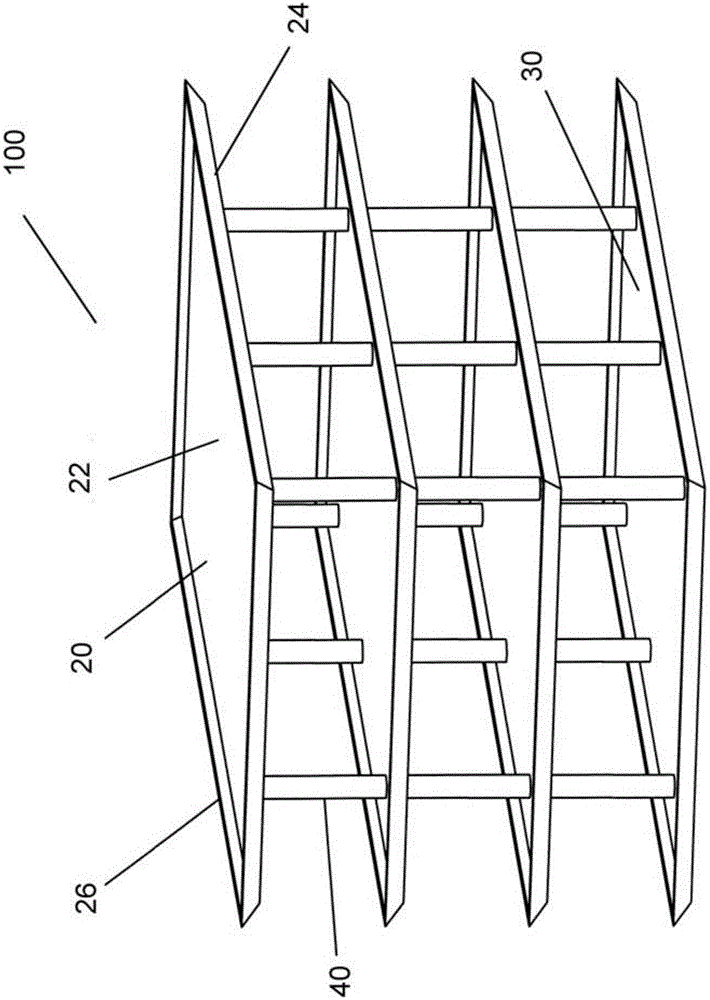

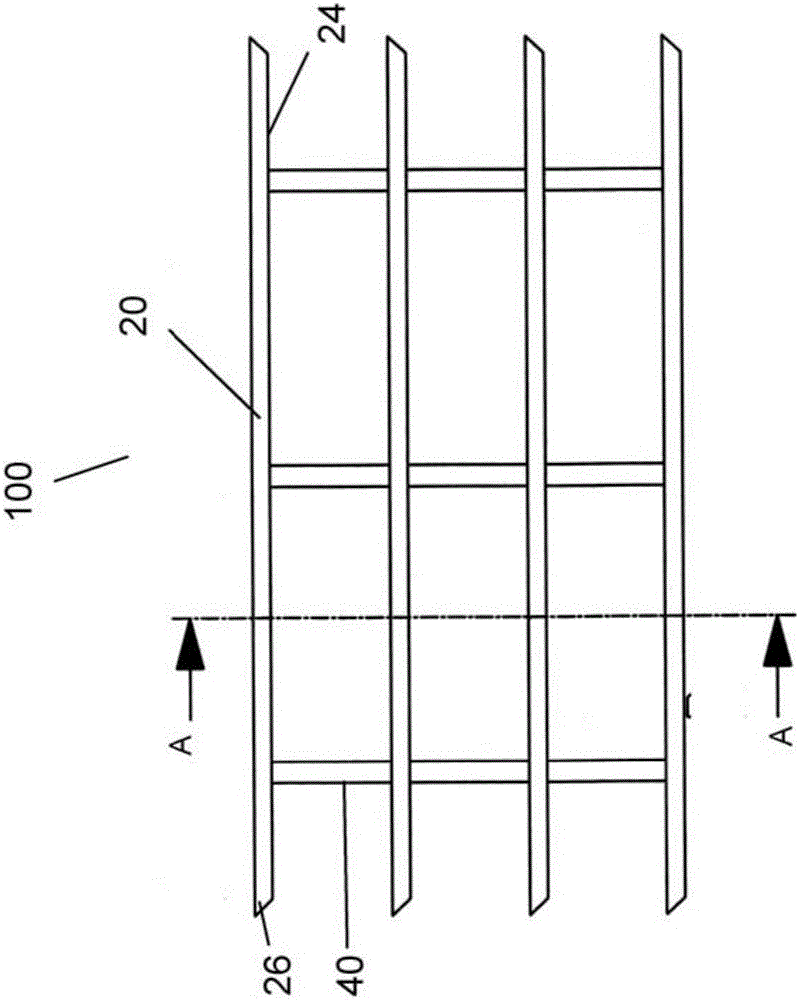

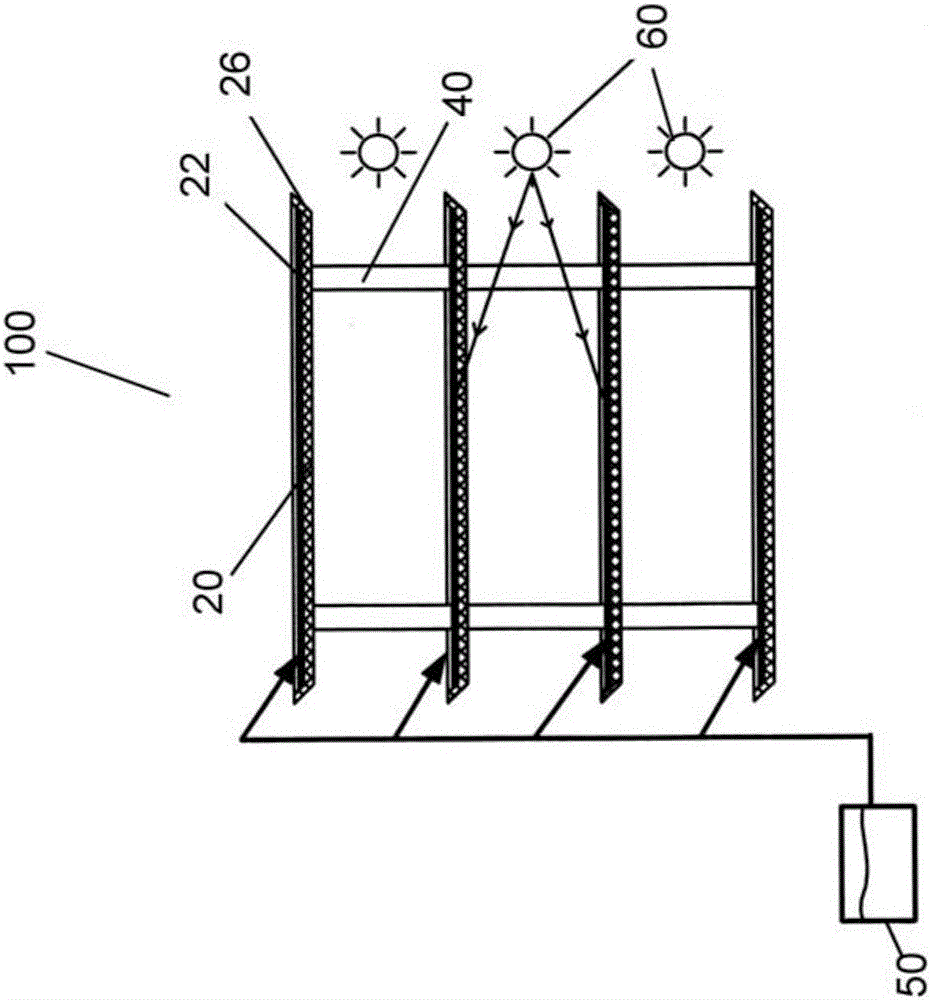

[0040] In general, the photobioreactor provided by the present invention is a kind of photobioreactor with multi-layer plates stacked, which includes a plurality of plates stacked in the vertical direction and arranged at predetermined intervals, and the plurality of plates Extending in the horizontal direction, each plate body has an upper surface and an opposite lower surface for placing the culture solution for cultivating the target photobiology, and the periphery of each plate body is provided with a corresponding plate protruding from the corresponding plate body. The cofferdam portion whose upper surface extends upward.

[0041] Figures 1 to 3 A photobioreactor 100 according to a preferred embodiment of the present invention is shown.

[0042] It can be seen from the figure that the photobioreactor 100 includes a plurality of plates 20 stacked in the vertical direction and a plurality of support columns 40 between adjacent plates. Each plate body 20 extends along the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com