Steel hot-stamped product with aluminum or aluminum alloy plating layer and manufacturing method thereof

A manufacturing method and aluminum alloy technology, applied in metal material coating process, coating, hot-dip plating process, etc., can solve problems such as unspecified stamping process, different appearance and color of stamped products, and changes in furnace atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

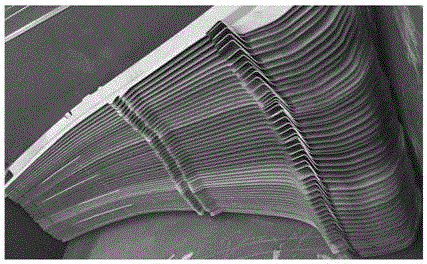

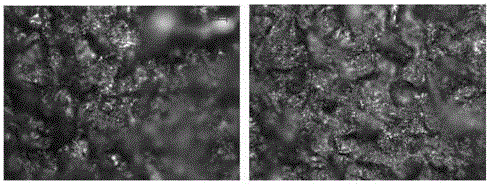

[0061] The 1.2mm aluminum alloy coated steel plate is laser blanked into a billet of a certain size and shape. The hot-dip plating solution consists of Si: 8.5%, Fe: 2.6%, and the rest is aluminum and unavoidable impurities. The billet enters the heating furnace, and the heating furnace The temperature is 950°C, the residence time is 3.5min, the oxygen content in the atmosphere in the furnace is 20%, it is transferred to the mold within 10s, the clamping speed is 100mm / s, the holding time is 10s, and the holding pressure is 10MPa. The appearance of the obtained product is as follows: image 3 As shown, the cross-sectional microstructure of the coating is as Figure 4 As shown, the proportion of martensite in the microstructure of the obtained hot stamping product substrate is higher than 95%, the hardness HV10 is 450, the total thickness of the coating is 43 μm, and the thickness of the alloy layer is 12 μm.

Embodiment 2

[0063] The 0.9mm aluminum alloy coated steel plate is laser blanked into a billet of a certain size and shape. The hot-dip plating solution consists of Si: 8.3%, Fe: 2.4%, and the rest is aluminum and unavoidable impurities. The billet enters the heating furnace, and the heating furnace The temperature is 940°C, the residence time is 5min, the oxygen content of the atmosphere in the furnace is 22%, it is transferred to the mold within 5s, the mold clamping speed is 50mm / s, the holding time is 4s, and the holding pressure is 8MPa. The proportion of martensite in the microstructure of the obtained hot stamping product substrate is higher than 97%, the hardness HV10 is 480, the total thickness of the coating is 50 μm, the thickness of the alloy layer is 15 μm, and the microstructure of the coating cross section is as follows: Figure 5 shown.

Embodiment 3

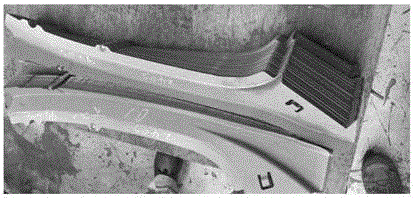

[0065] The 1.0mm aluminum alloy coated steel plate is laser blanked into a billet of a certain size and shape. The hot-dip plating solution consists of Si: 9.0%, Fe: 2.7%, and the rest is aluminum and unavoidable impurities. The billet enters the heating furnace, and the heating furnace The temperature is 930°C, the residence time is 7min, the oxygen content of the atmosphere in the furnace is 18%, it is transported to the mold within 8s, the mold clamping speed is 70mm / s, the holding time is 6s, and the holding pressure is 12MPa. The proportion of martensite in the microstructure of the substrate of the obtained hot stamping product is higher than 96%, the hardness HV10 is 490, the total thickness of the plating layer is 41 μm, and the thickness of the alloy layer is 11 μm. Figure 6 is the surface SEM morphology of hot stamping products, from Figure 6 It can be seen that the SEM appearance of the hot stamping product described in Example 3 of the present invention has certa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com