Preparation method of anti-coagulation hemodialysis membrane

A technology of hemodialysis and anticoagulation, which is applied in the field of preparation of anticoagulant hemodialysis membranes, can solve problems such as unsatisfactory anticoagulant performance, achieve improved hydrophilicity and anticoagulant performance, improve hydrophilicity, The effect of improving anticoagulant ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preparation method of the anticoagulant hemodialysis membrane of the present invention is carried out according to the following steps:

[0021] (1) Preparation of acrylonitrile-ethyl methacrylate copolymer.

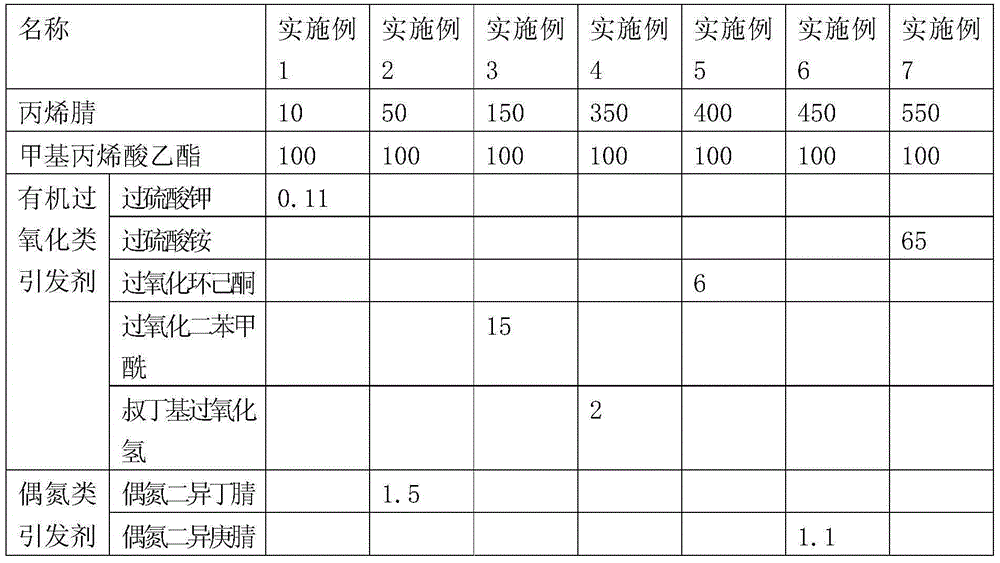

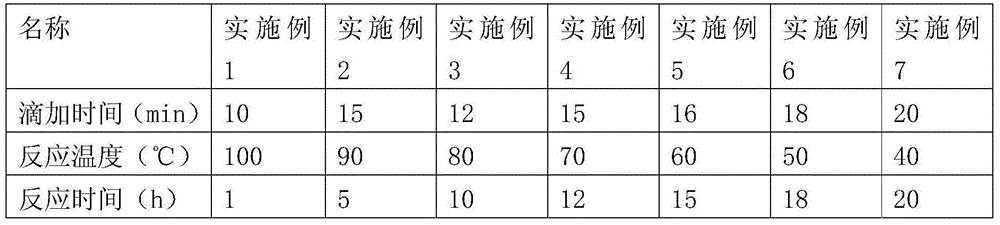

[0022] Add acrylonitrile and ethyl methacrylate into the reactor at a mass ratio of 0.1 to 5.5:1. Acrylonitrile and ethyl methacrylate at a mass ratio of 1.5 to 4.5:1. Use nitrogen bubbling to remove oxygen. Blow in nitrogen gas for 30 minutes to remove the dissolved oxygen. While stirring, the polymerization initiator is added dropwise to initiate radical polymerization. The mass ratio of the polymerization initiator of the present invention to acrylonitrile and ethyl methacrylate is 0.001 to 0.1:1. The mass ratio can be controlled at 0.002~0.06:1, the dropping time is controlled at 10~20min, the temperature is raised to 40~100℃ for polymerization reaction, the reaction time is controlled at 1~20h, and the reaction can be carried out under nitrogen protection. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com