Tubular motor, brushless motor control method, and motor with brake

A control method and brake technology, which is applied in the control field of motors with brakes, tubular motors, and brushless motors, can solve the problems of low assembly efficiency of tubular motors, and achieve the effect of reducing the number of parts, reducing costs, and efficient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] (first invention)

[0094] Using paragraphs (0054) to (0088), (0175) and Figure 1 to Figure 6 The first invention will be described.

[0095] Hereinafter, a tubular motor to which the present invention is applied will be described with reference to the drawings. In the following description, L is attached to the motor axis, L1 is attached to the output side where the motor shaft protrudes, and L2 is attached to the side opposite to the side where the motor shaft protrudes (opposite output side).

[0096] (the whole frame)

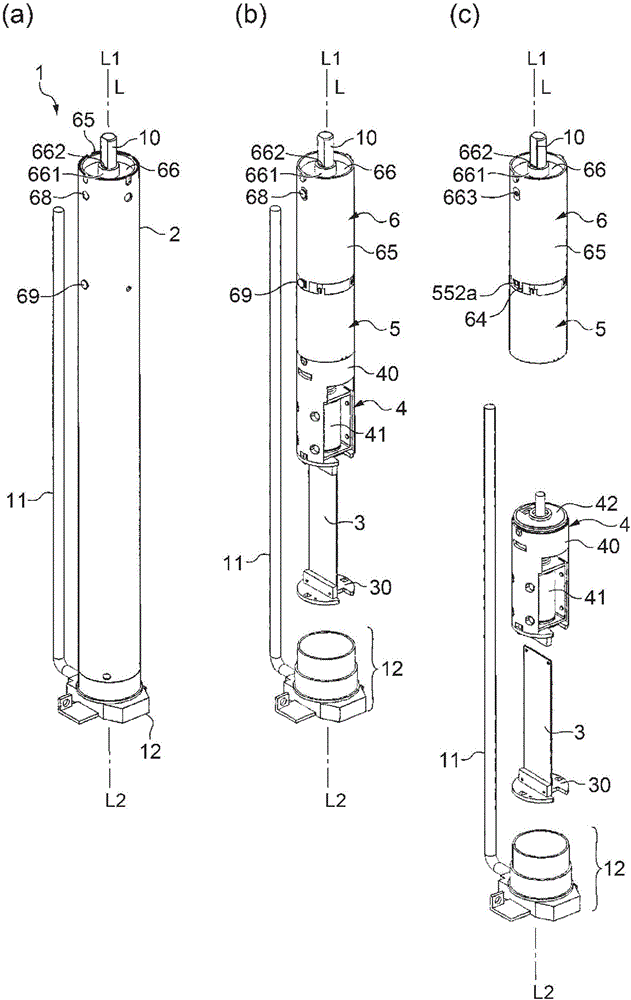

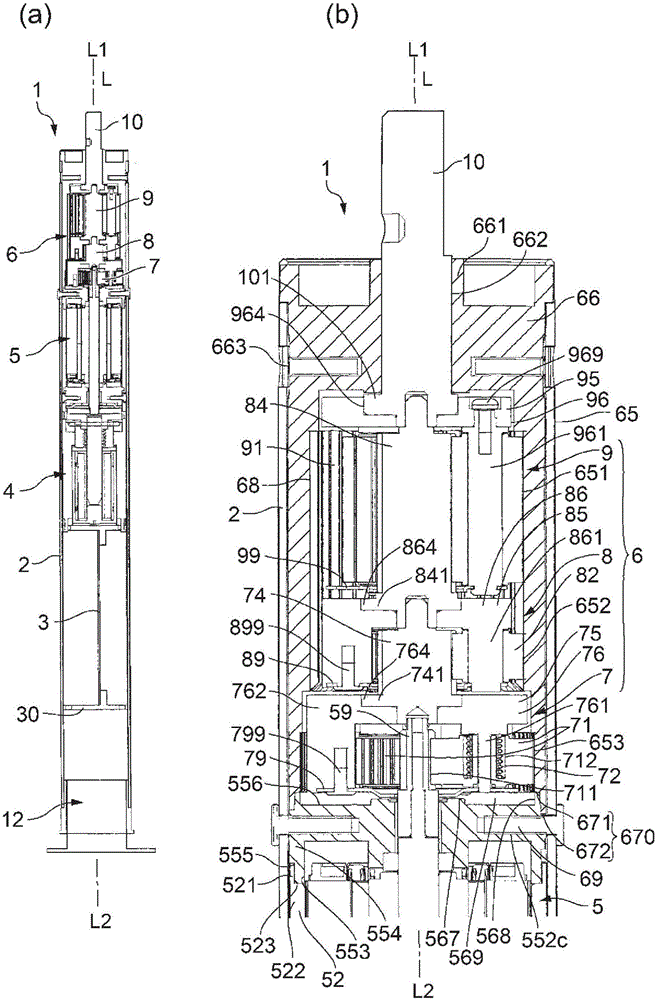

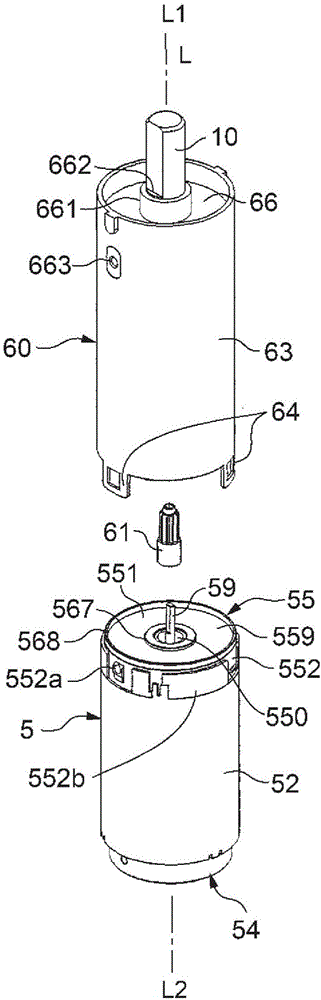

[0097] figure 1 is an explanatory diagram of a tubular motor 1 to which the present invention is applied, figure 1 (a), (b), and (c) are a perspective view of the tubular motor 1 , a perspective view of the tubular motor 1 with the casing 2 omitted, and an exploded perspective view of a unit housed inside the casing. figure 2 is a sectional view of a tubular motor 1 to which the present invention is applied, figure 2 (a) and (b) are cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com