Method for surface treatment of transparent part and part treated in this way

A processing method, a technology for parts, applied in the direction of methods of preventing contamination, cleaning methods and utensils, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] On the figures, the same numerical references designate the same elements.

[0047] The scale of the drawings has not been followed.

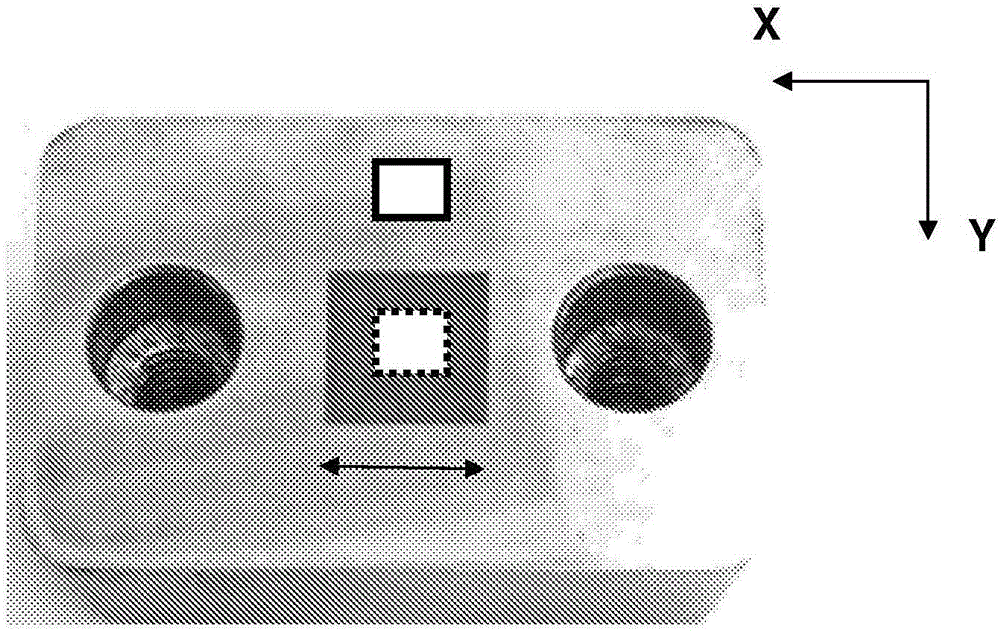

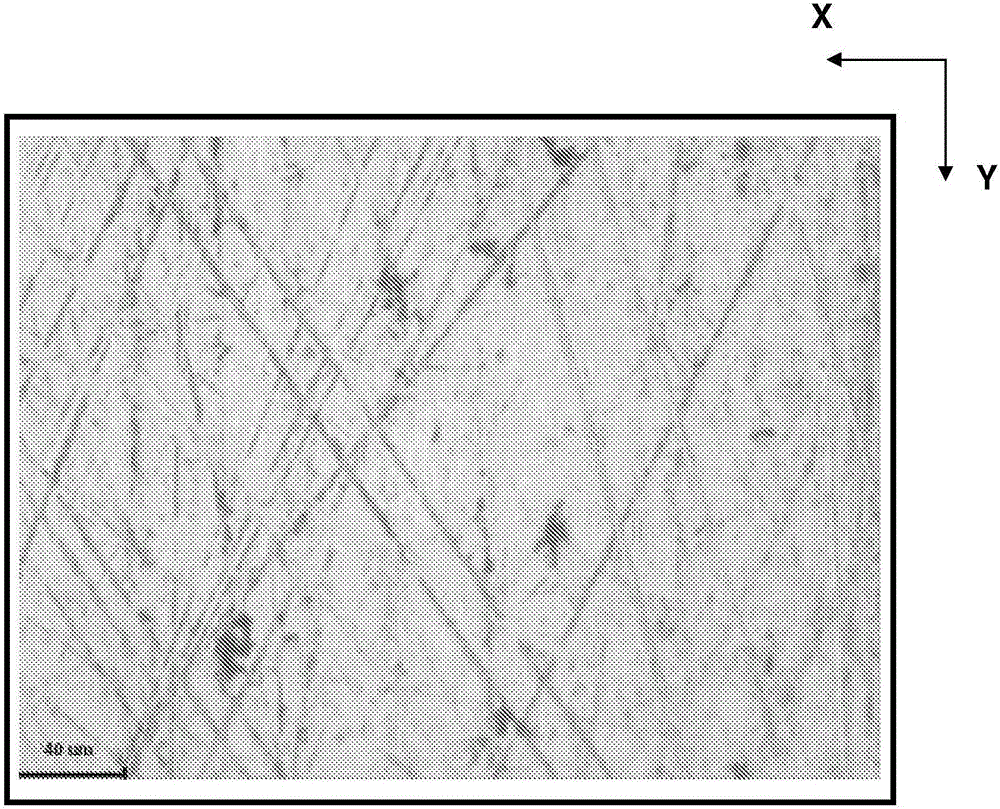

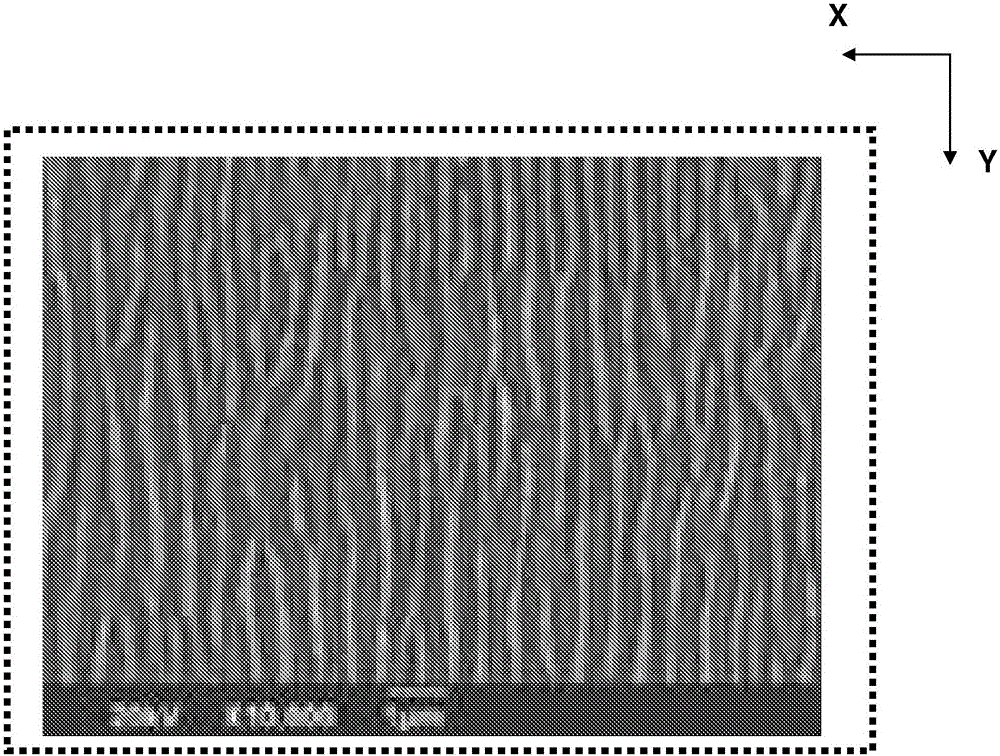

[0048]The method according to the invention advantageously involves deforming a metal mold texture (in particular made of steel) in order to produce a negative mold impression on a polymer (in particular polycarbonate) part obtained by injection moulding.

[0049] The engraving or texturing of the mold is advantageously carried out using a laser of the femtosecond type, while other means of mechanical texturing can be used, such as sandblasting, machining (milling), ...

[0050] Femtosecond lasers are capable of producing extremely short (approximately one hundred femtoseconds, i.e. approximately 1×10 -13 seconds) pulse. However, the duration of this pulse enables extremely high power.

[0051] The advantages of femtosecond laser are many:

[0052] - can deform the texture of industrial molds made of metal;

[0053] - Ability to pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com