Smart damping-varying semi-active vibration absorption rubber mat based on vibration generation

A technology of vibration power generation and variable damping, which is applied in the direction of generator/motor, non-rotating vibration suppression, electrical components, etc., can solve the problems of unsatisfactory vibration control, fixed performance parameters, narrow vibration frequency range, etc., and achieve the damping value Small, compact and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

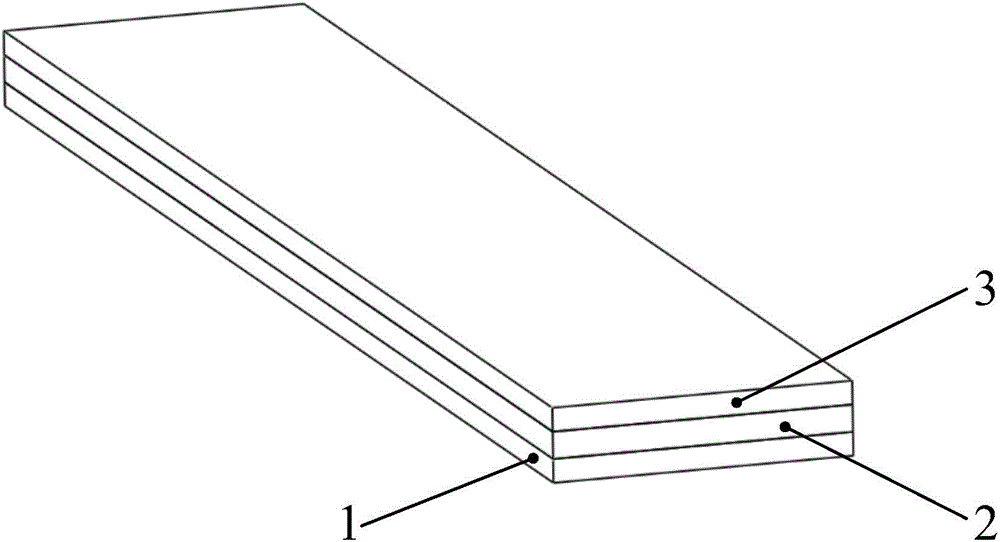

[0021] Such as figure 1 As shown, the vibration-absorbing rubber pad of the present invention includes a vibration power generation layer 1, a dielectric elastomer layer 2 and a rubber layer 3, and the vibration power generation layer, the dielectric elastomer layer, and the rubber layer are sequentially bonded to form a three-layer composite structure; The power generation layer is used as the inner layer of the vibration-absorbing rubber pad, and the rubber layer is used as the outer layer of the vibration-absorbing rubber pad.

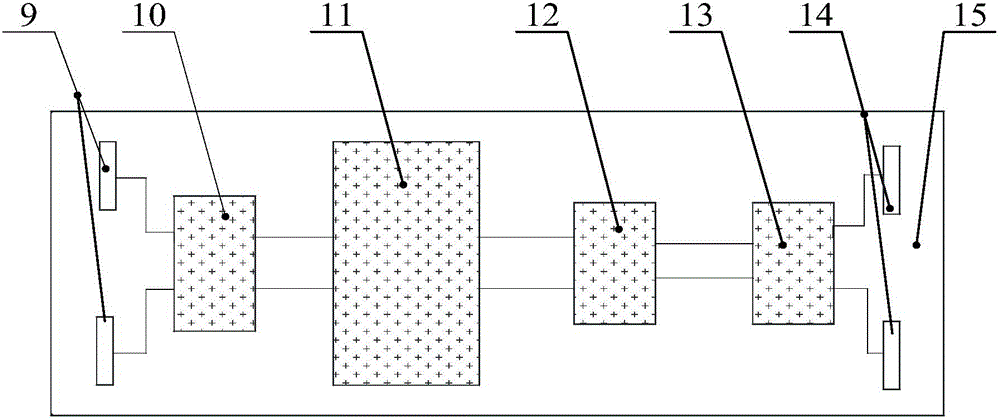

[0022] The dielectric elastic layer is an intelligent damping material composed of silicone rubber and PHT. When the voltage value output to the dielectric elastomer through the conductive electrode plate is high, the dielectric elastomer exhibits high damping characteristics; when the voltage value output to the dielectric elastomer through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com