New use of rubidium cesium compound, high-voltage electrolyte additive, high-voltage electrolyte and lithium ion battery

A lithium-ion battery and compound technology, applied in the fields of high-voltage electrolyte additives, high-voltage electrolytes and lithium-ion batteries, can solve the problems of poor battery cycle performance, inability to cycle stably, poor rate performance, etc., to achieve large discharge capacity, increase The effect of good cycle life and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

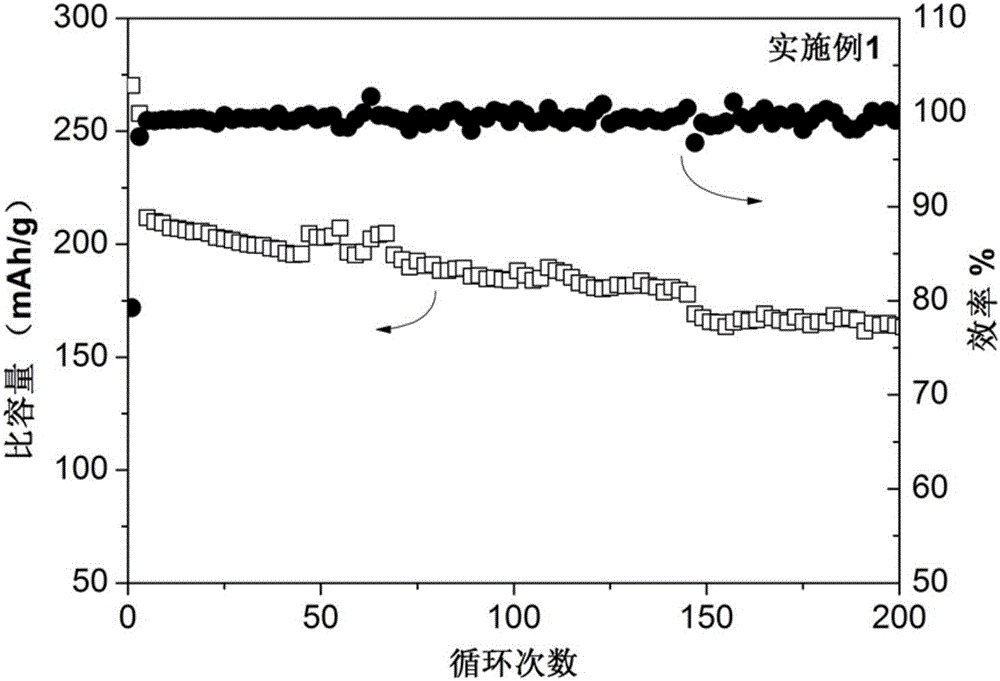

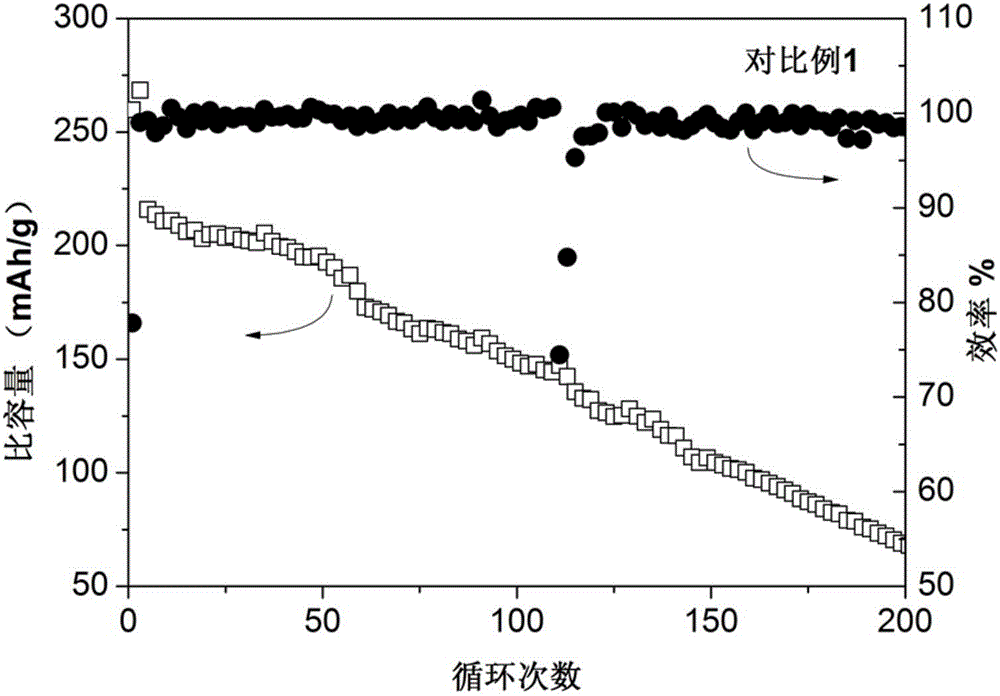

Embodiment 1

[0040] Mix ethylene carbonate, diethyl carbonate, propylene carbonate and fluoroethylene carbonate evenly, add lithium hexafluorophosphate, and finally add cesium bis(trifluoromethylsulfonyl)imide and mix evenly to obtain a high-voltage electrolyte. Among them, the volume ratio of ethylene carbonate, diethyl carbonate, propylene carbonate and fluoroethylene carbonate is 2:4:3:1, the concentration of lithium hexafluorophosphate is 1mol / L, bis(trifluoromethylsulfonyl) The mass percentage of cesium amine is 0.85%, and the mass percentage is the percentage of the additive in the total mass of the electrolyte.

[0041] Use this electrolyte to assemble a lithium-ion battery, using lithium-rich ternary Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 The material is the positive electrode, the lithium sheet is the negative electrode, and the Celgard diaphragm.

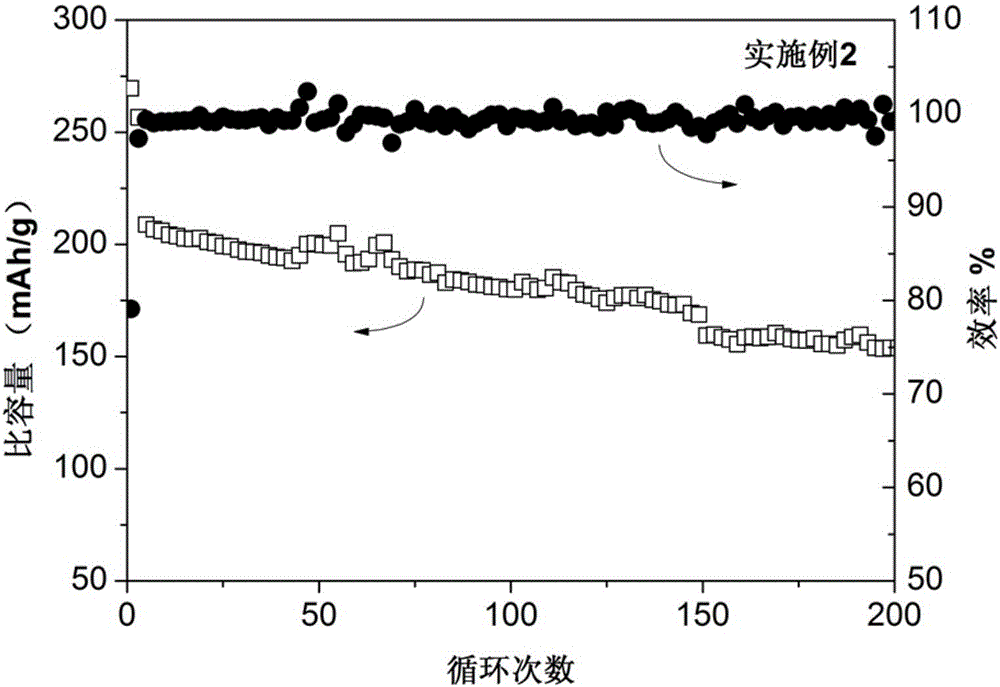

Embodiment 2

[0043] Mix ethylene carbonate, diethyl carbonate, propylene carbonate and fluoroethylene carbonate evenly, add lithium hexafluorophosphate, and finally add cesium hexafluorophosphate and mix evenly to obtain a high-voltage electrolyte. Among them, the volume ratio of ethylene carbonate, diethyl carbonate, propylene carbonate and fluoroethylene carbonate is 2:4:3:1, the concentration of lithium hexafluorophosphate is 0.8mol / L, and the mass percentage of cesium hexafluorophosphate is 0.6%, and the mass percentage is the percentage of the additive in the total mass of the electrolyte.

[0044] Use this electrolyte to assemble a lithium-ion battery, using lithium-rich ternary Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 The material is the positive electrode, the lithium sheet is the negative electrode, and the Celgard diaphragm.

Embodiment 3

[0046] Mix ethylene carbonate, ethyl methyl carbonate, propylene carbonate and sulfolane evenly, add lithium hexafluorophosphate and lithium boron dioxalate, and finally add cesium bis(trifluoromethylsulfonyl)imide and mix evenly to obtain a high-voltage electrolyte. Wherein, the volume ratio of ethylene carbonate / ethyl methyl carbonate / propylene carbonate / sulfolane is 2:3:3:2, the concentration of lithium hexafluorophosphate is 0.9mol / L, the concentration of lithium boron dioxalate is 0.1mol / L, two The mass percentage of cesium (trifluoromethylsulfonyl)imide is 5%, and the mass percentage is the percentage of the additive in the total mass of the electrolyte.

[0047] Use this electrolyte to assemble a lithium-ion battery, using lithium-rich ternary Li 1.2 Ni 0.13 co 0.13 mn 0.54 o 2 The material is the positive electrode, the lithium sheet is the negative electrode, and the Celgard diaphragm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com