Dry-type power capacitor with built-in pressure explosion-proof equipment

A technology for power capacitors and explosion-proof devices, which is applied to capacitors, fixed capacitor casings/packages, and components of fixed capacitors, etc., can solve the problems of insufficient service life, safety and reliability concerns, affecting the stretching action of the casing, etc., and is not easy to expand. Deformation, safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

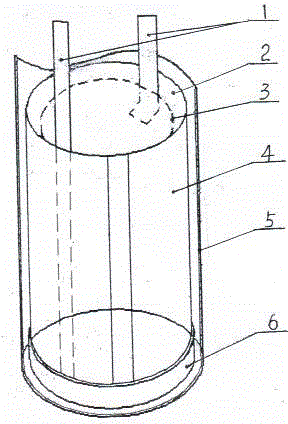

[0009] Examples, see attached figure 1 , The dry-type power capacitor with built-in pressure explosion-proof device is fixed and connected to the upper and lower ends of the capacitor core 3, respectively, and the outer periphery of the capacitor core 3 is wrapped with the Mylar sheet 4, and the capacitor core 3 and the Mylar sheet 4 There should be a gap between them. The bottom end of the capacitor core 3 wrapped by the Mylar sheet 4 is provided with a lower insulating sleeve 6, and the capacitor core 3 and the lower insulating sleeve 6 are sealed with Mara tape. Epoxy resin 2 is used for potting between the Mylar sheet 4 and the capacitor core 3, and the capacitor core 3 after the epoxy resin 2 is cured is completely wrapped and covered by the epoxy resin 2, which is firm and stable. The outer periphery of the mylar sheet 4 and the lower insulating sleeve 6 is wrapped with an aluminum shell 5, and a gap is provided between the aluminum shell 5 and the mylar sheet 4 package. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com