Quasi-two-pole winding-structure lead-acid battery and making method

A technology of lead-acid battery and pole roll, which is applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc. It can solve the problem that the battery life is not as good as that of the wound cylindrical battery, the opening pressure of the vent valve is low, and it is not suitable for large-capacity batteries. and other problems, to achieve the effect of improving the sealing reaction efficiency, high valve opening pressure, and excellent high-current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

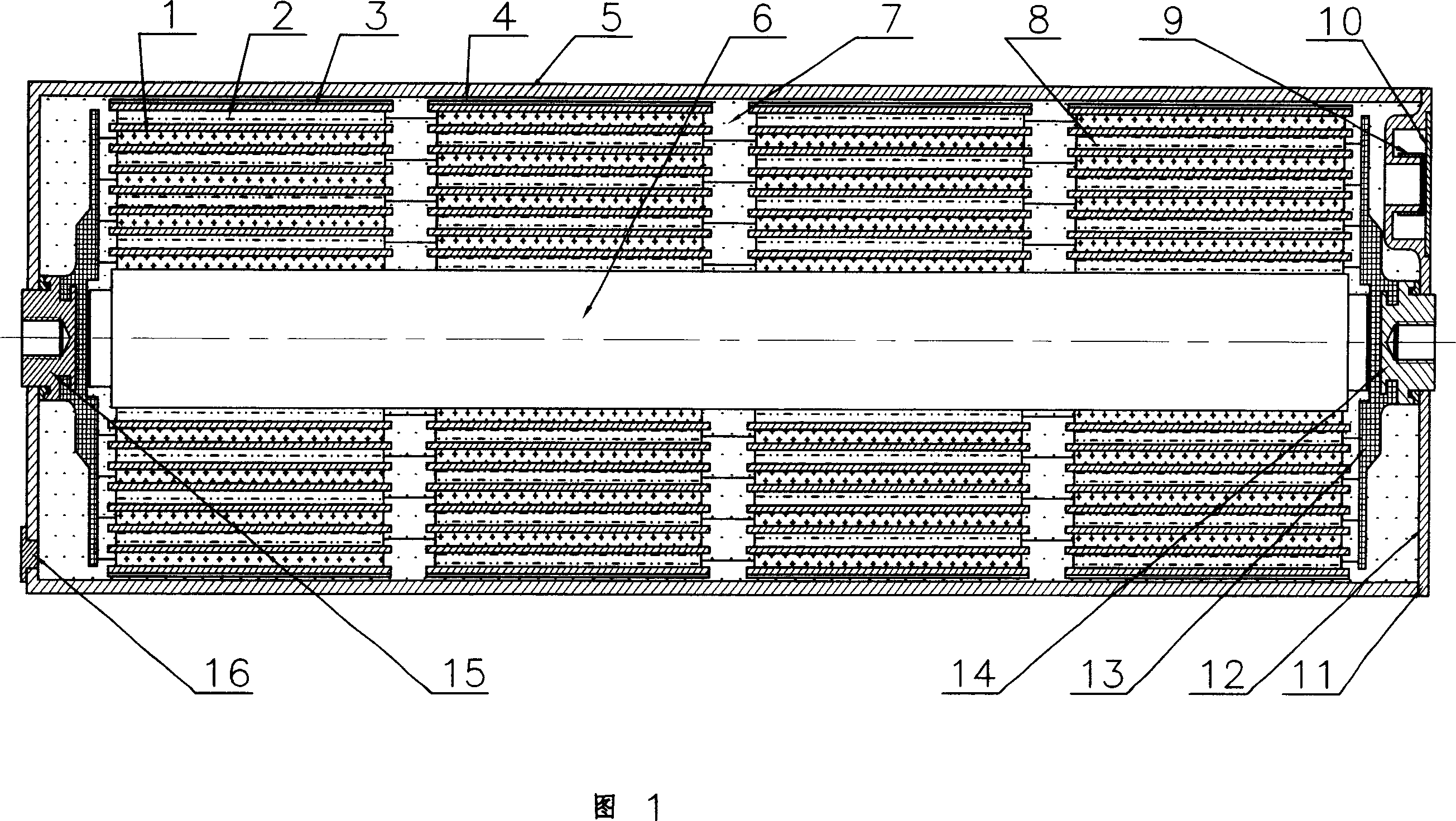

[0041] As shown in Figures 1 to 6: a lead-acid battery with a quasi-bipolar winding structure, including a battery box 5, a box cover 11 and terminals, the terminals are located at both ends of the battery box, and the positive terminal 15 is located at the bottom of the battery box In the center, the negative terminal 14 is sleeved on the box cover 11 and sealed on the battery box 5 through the box cover 11. The box cover 11 is provided with a safety valve 9 and a valve cover 10, and the terminals at both ends are respectively connected to the bus bar 13 inwardly. A sealing gasket 12 is arranged between the row 13 and the terminal, a valve hole for injecting electrolyte is provided at the bottom of the battery case 5, a process plug 16 is arranged on the valve hole, a positive plate 1, a negative plate 8, Bipolar plate 2, mandrel 6, diaphragm 3 and plastic fixture 4;

[0042] The bipolar plate 2 is coated with positive and negative active materials respectively on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com