Lubricating oil pressure difference false alarm fault point searching method

A technology of false alarms and fault points, which is applied in the direction of engine testing, machine/structural component testing, and measuring devices, can solve problems such as flight safety hazards, affecting flight missions, and endangering flight safety, so as to achieve strong test pertinence, Avoid repetitive and disordered labor and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

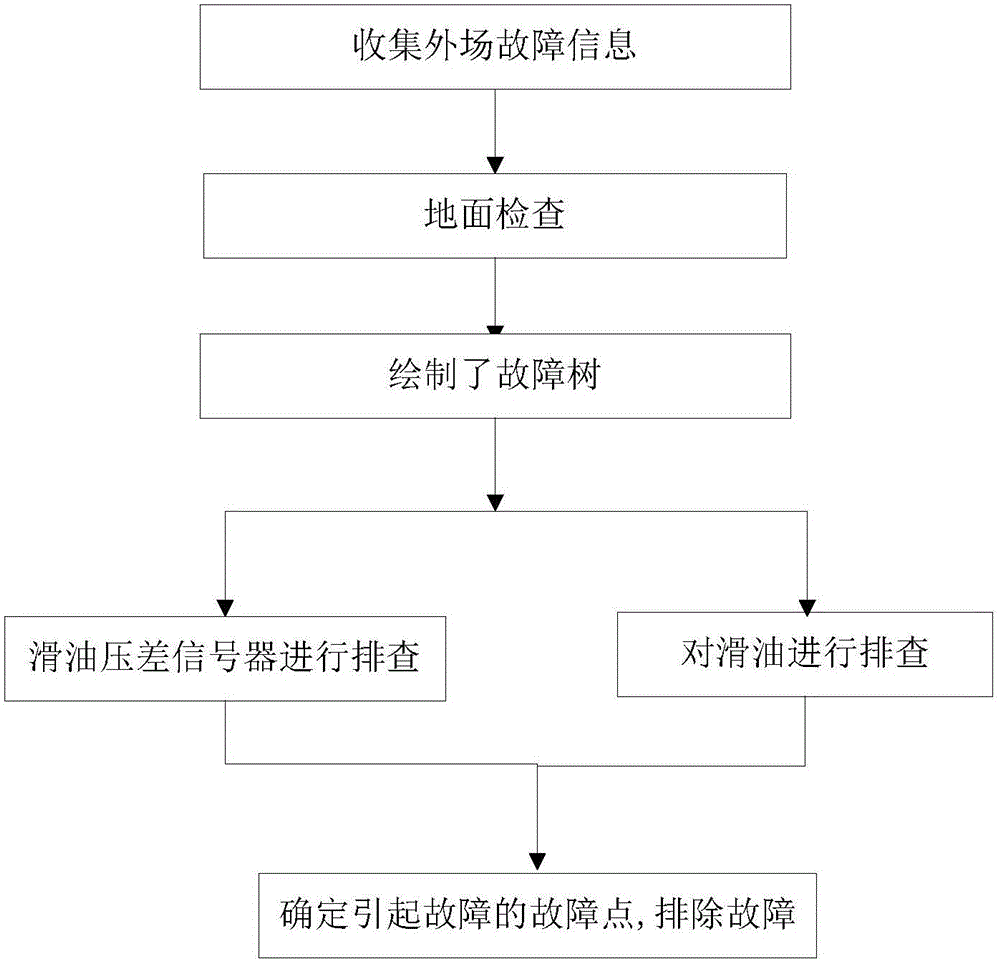

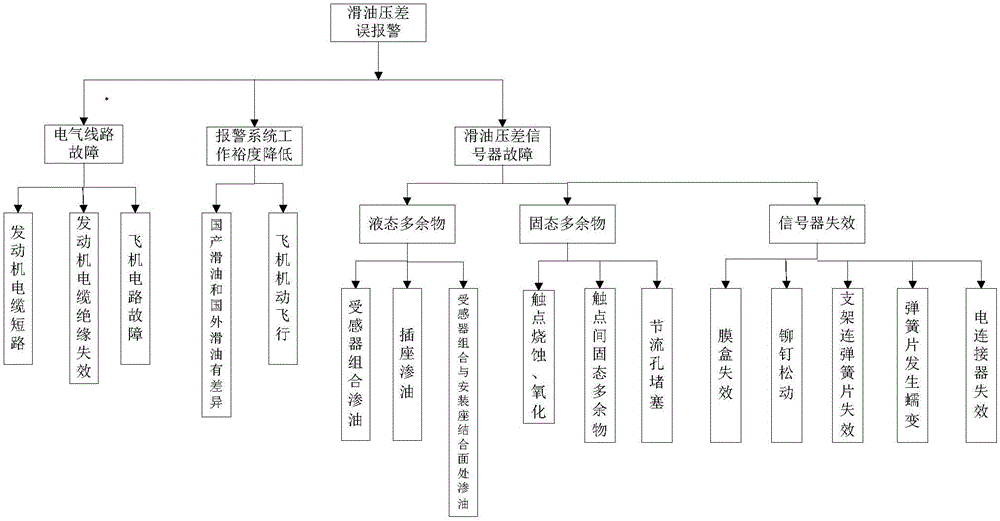

Method used

Image

Examples

example 1

[0068] Example No. 1 When the product is pressurized to the boosting working point after returning to the factory, the alarm light and the non-alarm light are turned on at the same time, and the fault phenomenon has been repeated many times in the factory, and the fault phenomenon has not appeared. , the contact gap is found to be out of tolerance by testing the contact gap. It can be judged that the reason why the alarm light does not go out is that the gap between the contacts on the combination of the lever and the spring sheet is too small, which causes the normally closed point on the switch component to not be completely disconnected, and the alarm light does not go out. Fault No. 1 is also the reason.

[0069] b. The characteristics of the capsule of the sensory part are too poor

example 2

[0070] Example No. 2 The faulty product returned to the factory for test work point out of tolerance (requirement (kPa): step-down point I: 103.4±2.74, boost point I+ΔI, ΔI: 4.8~8.92, measured value: boost point 110.4kPa, drop The pressure point is 99.2kPa), the product is decomposed and the performance test of the sensor film is carried out. It is found that the sensor film is out of tolerance, so that the alarm light does not alarm when it is a normal alarm.

[0071] c. Product welding quality problems

[0072] Example No. 3, the faulty product returned to the factory for testing, and the fault recurred many times, and the welding wire was found to be short-circuited by opening the meter; the No. 3 fault was also due to the poor contact of the socket due to the welding quality problem, so that the alarm light did not alarm when it was a normal alarm.

[0073] Corrective Action

[0074] In view of the faults caused by the out-of-tolerance contact gap, out-of-tolerance charac...

Embodiment 1

[0079] Oil accumulation test in the contact cavity of the lubricating oil differential pressure annunciator:

[0080] Six tests were carried out, and it was finally verified that the external oil vapor could enter the contact cavity of the lubricating oil differential pressure signal from the joint surface of the product and the joint of the cover plate and the casing. The six main trials are as follows:

[0081] ①Room temperature oil leakage test - immerse the product mounting seat in lubricating oil for 295 hours at room temperature, and no oil enters the contact cavity.

[0082] ②Room temperature oil immersion test - immerse the product in lubricating oil for 90 hours at room temperature except for the electrical socket, and no oil enters the contact cavity.

[0083] ③Pressure test at room temperature - pressurize (lubricating oil) 1Mpa for each of the high and low pressure chambers of the sensing part of the product, and at the same time simulate the working state of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com