Self-lubricating high-precision composite shaft, manufacturing method, shield pump, motor and fan

A composite shaft and high-precision technology, which is applied in the fields of motors, fans, and shielded pumps, can solve the problems of high corrosion resistance, high hardness, large precision changes, and high cost of ceramic shafts, and achieve good lubricity and good precision stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

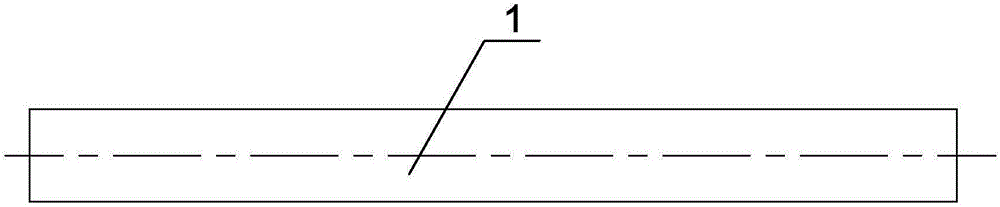

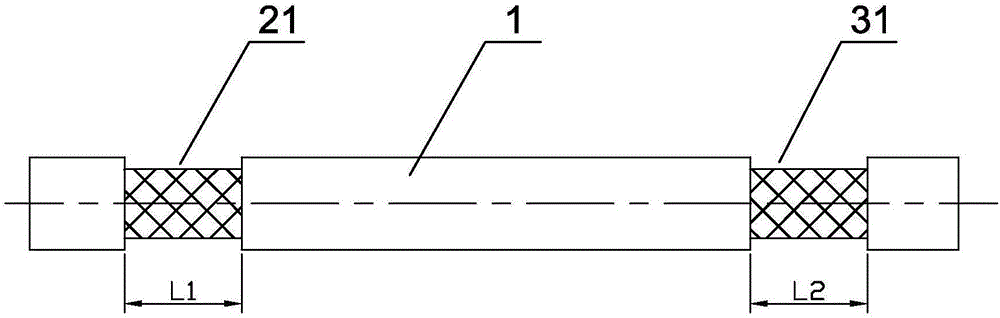

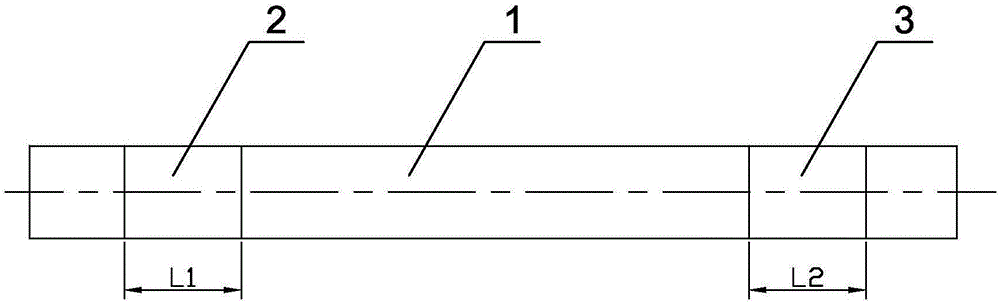

[0042] Such as Figure 1 ~ Figure 3 As shown, the self-lubricating high-precision composite shaft of this embodiment includes a shaft body 1. The friction part of the shaft body 1 that matches the sliding bearing is provided with annular grooves 21, 31, and the depth of the annular grooves 21, 31 is 0.5 mm, the depth is preferably within the range of 0.2-1.0mm. The widths L1, L2 of the annular grooves 21, 31 are the widths of the friction rings 2, 3, and are not less than the axial direction of the sliding bearing fitted here. The length of the ring grooves 21, 31 is filled with self-lubricating polymer polymer to form the ring friction rings 2, 3 through the injection molding process. The friction rings 2, 3 are in the ring grooves 21, 31 with the The shaft body 1 is firmly combined into one body, and the surface roughness of the annular grooves 21, 31 is not less than Ra6.3, and the roughness ensures a firm combination of the injection molding materials. After injection moldi...

Embodiment 2

[0046] This embodiment is a miniature canned motor pump (hot water circulating pump), including the self-lubricating high-precision composite shaft in the first embodiment, the shaft body 1 is made of metal, and the self-lubricating high The sliding bearing adapted to the precision composite shaft is made of ceramics. The two cooperate to achieve the best friction, that is, the cooperation of soft and hard materials, which solves the problem of the lack of lubricity of the ceramic shaft in the existing canned motor pump. The problem of easy wear by friction, the problem of large friction noise, and the problem of easy breakage are lower in cost. Such a high-hardness ceramic bearing and the metal shaft body in this embodiment and the self-lubricating material on the friction part of the metal shaft body form a perfect friction pair, which not only solves the problem of the shaft, but also solves the problem of friction.

Embodiment 3

[0048] This embodiment is a miniature high-temperature motor, including the self-lubricating high-precision composite shaft in the first embodiment. The sliding bearing that is adapted to the self-lubricating high-precision composite shaft in the motor adopts an oil-impregnated bearing, and its cost is low. The self-lubricating material of the friction part solves the problem of lubrication and wear resistance under oil-free conditions, which solves the problem of large noise and short life of the motor after running for a period of time under high temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com