Non-woven fabric coil with printed patterns

A technology of printing patterns and non-woven fabrics, applied in printing, non-woven fabrics, printing devices, etc., can solve the problems of difficult adjustment and setting of air permeability requirements, difficulty in printing non-woven fabrics, unfavorable diaper processing, etc., and achieve easy proficiency Putting on and taking off, improving surface activation energy, and improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

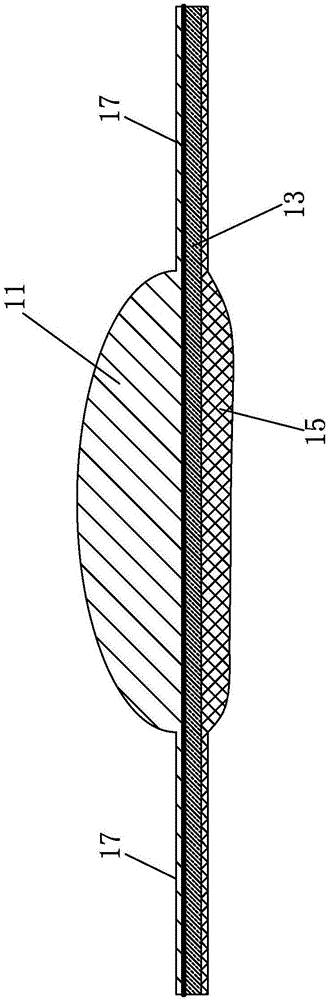

[0024] Such as figure 1 As shown, a non-woven fabric roll with printed patterns has an air permeability of 0-3500L / m 2 / s, the weight is 25 grams to 125 grams per square meter, including a top fiber layer 11, a middle printing layer 13 (the weight is 2 grams to 25 grams per square meter) and a bottom fiber layer 15 connected in sequence , the fineness of the fiber used in the top surface fiber layer 11 and the bottom surface fiber layer 15 is 2.0D, and the fineness of the fiber used in the middle printing layer 13 is 0.2D, and one color or multi-color ink printing pattern is printed on the middle printing layer 13, and the top surface fiber The layer 11, the middle printing layer 13 and the bottom fiber layer 15 are thermally bonded by hot pressing points, and the area of the concave region 17 formed by the hot pressing points accounts for 5-70% (preferably 25-50%) of the total area;

[0025] Its preparation method comprises the following steps:

[0026] (1) forming the bo...

Embodiment 2

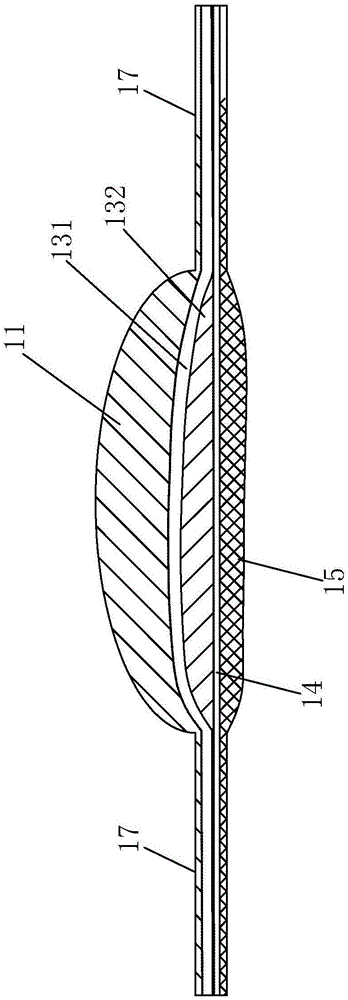

[0033] Such as figure 2 As shown, a non-woven fabric roll with printed patterns has an air permeability of 0-3500L / m 2 / s, the weight is 25 grams to 125 grams per square meter, including a top fiber layer 11, a first intermediate printing layer 131 (the weight is 2 grams to 25 grams per square meter), a second Intermediate printing layer 132 (gram weight is 2 grams to 25 grams per square meter), an intermediate fiber layer 14 and a bottom surface fiber layer 15, the fineness of fibers used in the top surface fiber layer 11, the middle fiber layer 14 and the bottom surface fiber layer 15 are greater than 1.0D, the fineness of the fibers used in the first intermediate printing layer 131 and the second intermediate printing layer 132 is less than 0.3D, the first intermediate printing layer 131 and the second intermediate printing layer 132 constitute a total printing layer, and the total printing layer is printed One-color or multi-color ink printing patterns, the top surface f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com