High-strength high-silicon aluminum alloy containing trace rare earth and preparation method thereof and application

A high-silicon aluminum alloy and rare earth technology, applied in the field of functional material development, can solve the problems of silicon-aluminum alloy composition segregation, low comprehensive performance, easy generation of holes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare Al-50Si-0.4Sc silicon aluminum alloy.

[0044] 1) The raw material is single crystal silicon, high-purity aluminum (99.998~99.999% Al), and Al-Sc alloy with 2% Sc content. The alloying elements are mixed in the following proportions: silicon: 50%, scandium: 0.4%, the balance For aluminum.

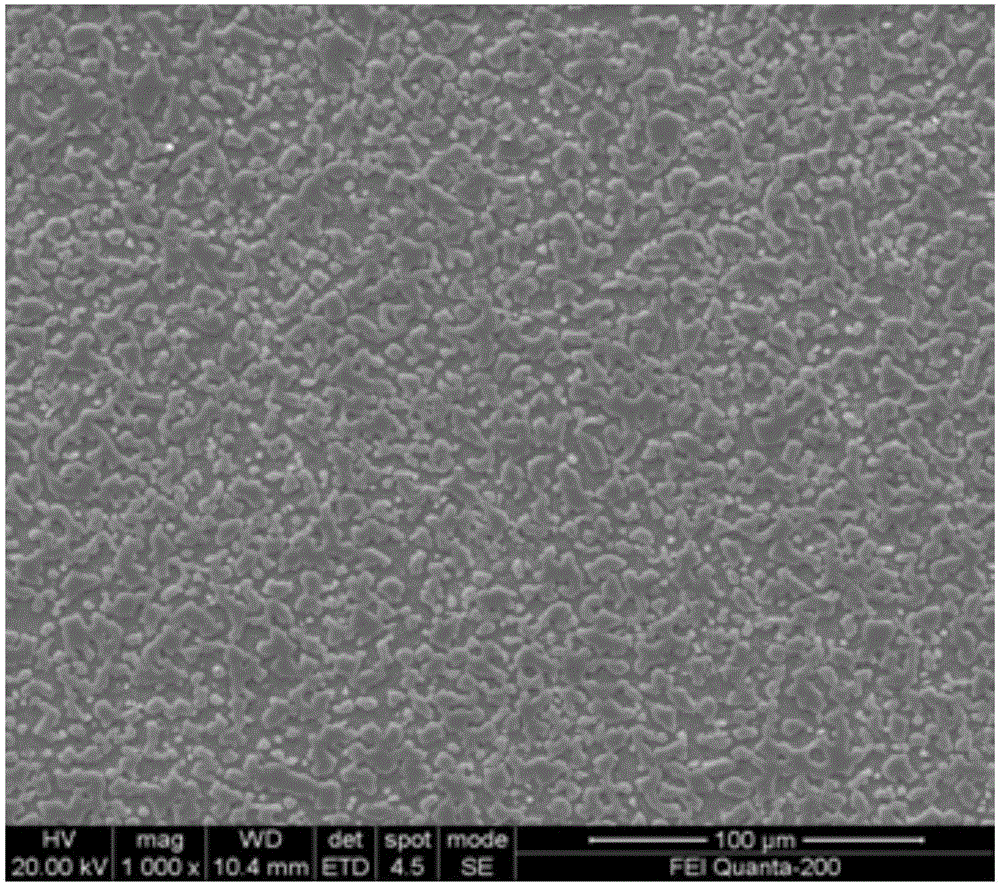

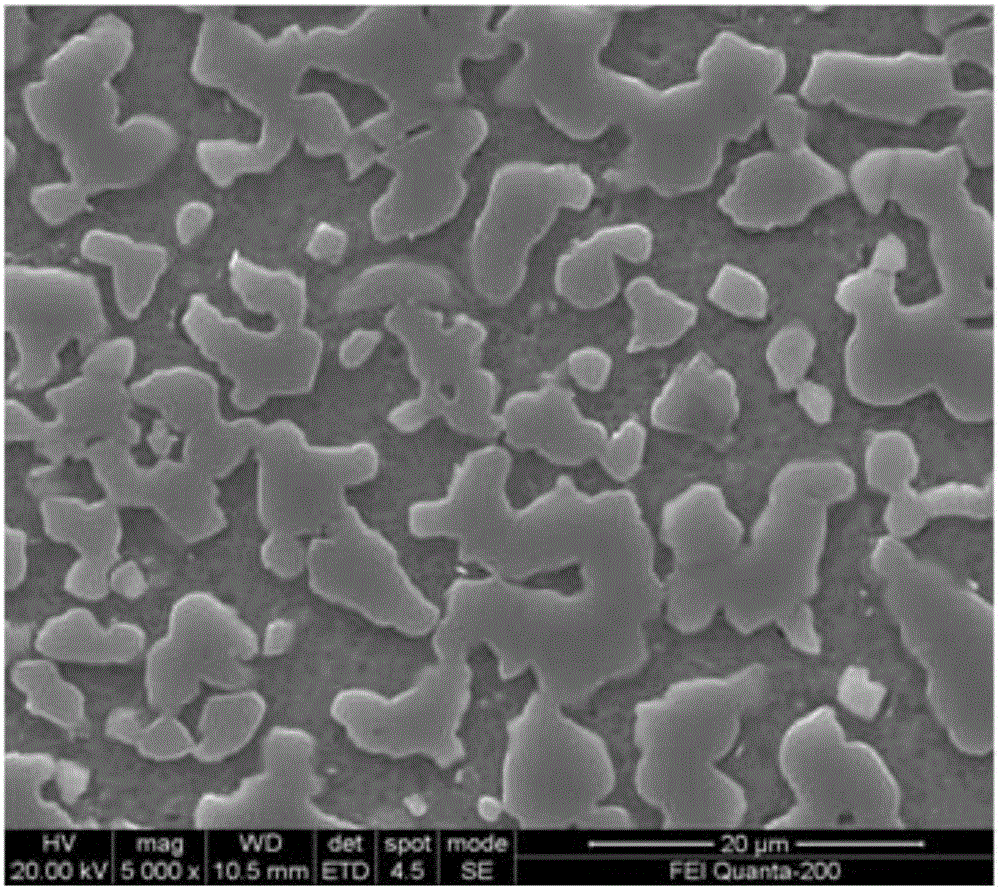

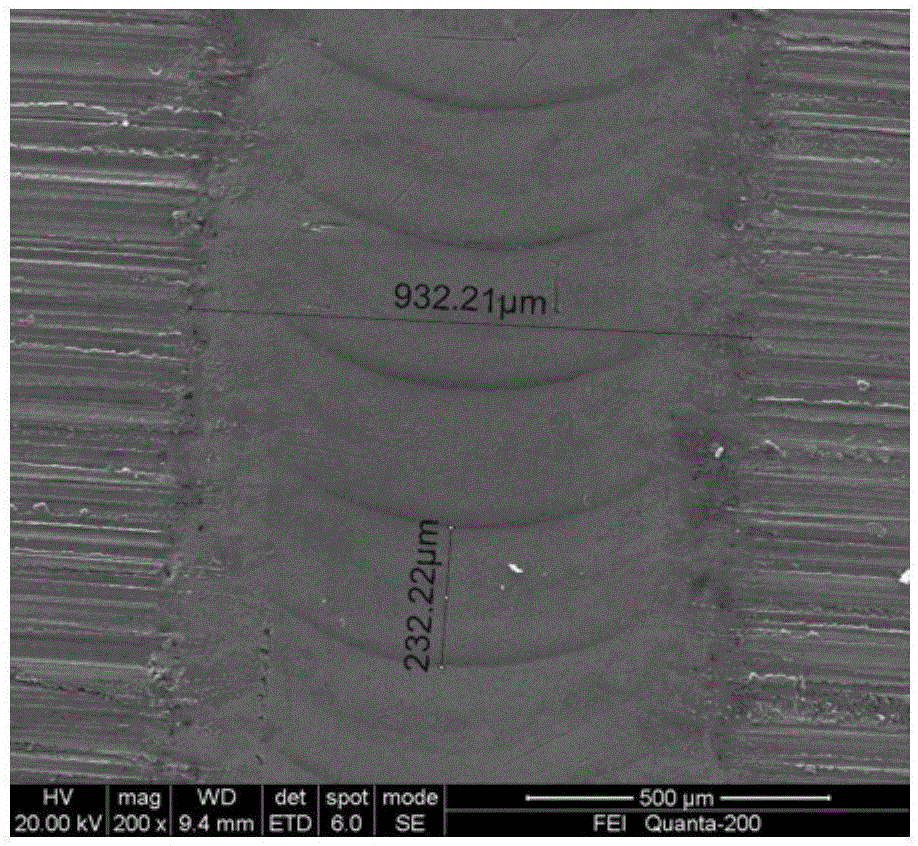

[0045] 2) Raise the high-purity aluminum ingot to 850°C. After the aluminum ingots are all melted, the temperature is raised to 1300°C, and then the monocrystalline silicon is added in batches. When the monocrystalline silicon is all melted and cooled to 760°C, the Al-Sc master alloy is added. Stir for 5 minutes, cover the slagging with 30% NaCl+47% KCl+23% cryolite, and degas with hexachlorohexane, let it stand for 10 minutes, pour the melt into a tundish with a preheating temperature of 950℃, and open it at the same time High-pressure nitrogen gas, an atomization pressure of 1.2 MPa, and a receiving distance of the deposition disk 630 mm, to obtain a deposition ingot with a dia...

Embodiment 2

[0058] Prepare Al-50Si-0.4Zr silicon aluminum alloy.

[0059] 1) The raw material is single crystal silicon, high-purity aluminum (99.998~99.999% Al), and Al-Zr alloy with a Zr content of 10%. The alloying elements are proportioned as follows: silicon: 50%, zirconium: 0.4%, the balance For aluminum.

[0060] 2) Raise the high-purity aluminum ingot to 850°C. After the aluminum ingots are all melted, the temperature is raised to 1300°C, and then the monocrystalline silicon is added in batches. After the monocrystalline silicon is all melted and cooled to 760°C, the Al-Zr master alloy is added. Stir for 5 minutes, cover the slagging with 30% NaCl+47% KCl+23% cryolite, and degas with hexachlorohexane, let it stand for 10 minutes, pour the melt into a tundish with a preheating temperature of 950℃, and open it at the same time High-pressure nitrogen gas, an atomization pressure of 1.2 MPa, and a receiving distance of the deposition disk 630 mm, to obtain a deposition ingot with a diamet...

Embodiment 3

[0065] Prepare Al-50Si-0.2Sc-0.4Zr silicon aluminum alloy.

[0066] 1) The raw materials are single crystal silicon, high-purity aluminum (99.998~99.999% Al), Al-Sc alloy with 2% Sc content, and Al-Zr alloy with 10% Zr content. The alloying elements are mixed in the following proportions: Silicon : 50%, scandium: 0.2%, zirconium: 0.4%, the balance is aluminum.

[0067] 2) The high-purity aluminum ingot is heated to 850°C, after the aluminum ingots are all melted, the temperature is raised to 1300°C, monocrystalline silicon is added in batches, and the temperature is reduced to 760°C after all the monocrystalline silicon is melted, and the Al-Sc master alloy and Al-Zr master alloy, fully stirred for 5min, covered slagging with 30%NaCl+47%KCl+23% cryolite, and degassed with hexachlorohexane, let stand for 10min, pour the melt into the preheating temperature of 950℃ In the tundish, the high-pressure nitrogen was turned on at the same time, the atomization pressure was 1.2MPa, the rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com