Method for removing chlorine in copper sulfate solution by copper refining slag

A copper sulfate solution and copper refining technology, which is applied in the field of copper refining slag to remove chlorine in copper sulfate solution, can solve the problems of low adsorption capacity of exchange resin, easy leakage, high components of regenerated water treatment, etc., and achieve low production cost and wide sources , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

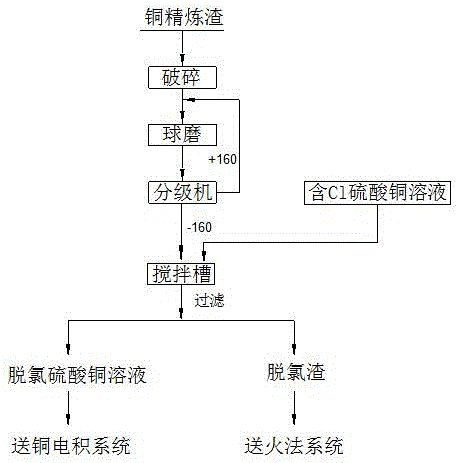

Image

Examples

Embodiment 1

[0028] The composition of a copper sulfate leach solution is shown in Table 1.

[0029] Table 1 Copper sulfate leaching solution (g / L)

[0030] project H2SO4 Cu Cl Copper Sulfate Leaching Solution 91.46 83.79 3.65

[0031] (1) Crushing and ball milling the copper refining slag to pass 120 mesh, the copper refining slag (dry basis) contains 39.95% copper.

[0032] (2) The concentration of Cl in the copper sulfate leaching solution is 3.65g / L, and the volume is 1L. Add 18.2g of the refining slag obtained in step (1), heat the solution to 65-70°C, stir and react for 60min, then suction filter, and the filtrate contains 50mg / L of chlorine.

Embodiment 2

[0034] The composition of a copper leaching solution is shown in Table 2.

[0035] Table 2 Copper leaching solution (g / L)

[0036] project H2SO4 Cu Cl Copper Sulfate Leaching Solution 94.39 75.6 2.92

[0037] (1) Crushing and ball milling the copper refining slag to pass 200 mesh, the copper refining slag (wet basis) contains 40.18% of copper;

[0038] (2) The concentration of Cl in the copper sulfate leaching solution is 2.92g / L, and the volume is 1L. Add 17.52g of refining slag (wet basis) obtained in step (1), heat the solution to 65-70°C, stir and react for 60min, then suction filter, the filtrate contains chlorine 100mg / L.

[0039] Copper refining slag removes chlorine in copper sulfate solution, and can treat copper sulfate solution with chloride ions in the range of 0.1-10g / L, and the concentration of chloride ions in copper sulfate solution can be reduced to 100mg / L as long as an appropriate amount is added.

[0040] The invention has simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com