Refining slag for bearing steel production and smelting process of refining slag

A technology for refining slag and bearing steel, applied in the field of steelmaking and refining, to achieve the effects of reducing Ti content, improving quality, and improving submerged arc effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Bearing steel (8 furnaces) smelted using the refining slag of the present invention and Zheng Shaobo etc. in May 2005 China Special Steel Annual Conference 2005 Proceedings "Control of Ti Content in High Carbon Chromium Bearing Steel" adopts silicon manganese pretreatment Deoxidation, high oxygen site plus ferrochrome and low-alkalinity refining slag are compared, see Table 1, the Ti content level in the steel controlled by the two slag systems is equivalent, and the oxygen content of the bearing steel smelted with the refining slag provided by the invention is lower, fully satisfying High standard bearing steel requirements.

[0023] Table 1 Index comparison of bearing steel smelted with low-alkalinity refining slag and refining slag provided by the present invention (%)

[0024]

Embodiment 2

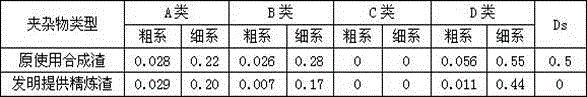

[0026] Comparative analysis of bearing steel smelted with synthetic slag (10 furnace steels) and bearing steel smelted with refining slag provided by the present invention (10 furnace steels), through sulfur content in steel, titanium content in steel, TiO2 content in refining slag, casting See Table 2 and Table 3 for the comparison of total oxygen content and inclusions in the billet. It can be seen that the quality of the bearing steel smelted using the refining slag provided by the present invention is obviously better than that of the original bearing steel smelted using synthetic slag.

[0027] index S content in steel Ti content in steel Refining slag TiO 2 content

Total oxygen content Oxygen content ≤ 8ppm ratio Originally used synthetic slag 0.0023 0.0028 0.47 0.0009 56% The invention provides refining slag 0.0010 0.0013 0.22 0.0006 100%

[0028] Table 3 Comparison of inclusions in bearing steel smelted with the original sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com