Culture medium for effectively prolonging survival time of lactic acid bacteria and preparation method of culture medium

A technology of lactic acid bacteria and survival period, applied in the direction of bacteria, etc., can solve problems such as unsatisfactory effects, and achieve the effects of increasing carbon source intake channels, enhancing vitality, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

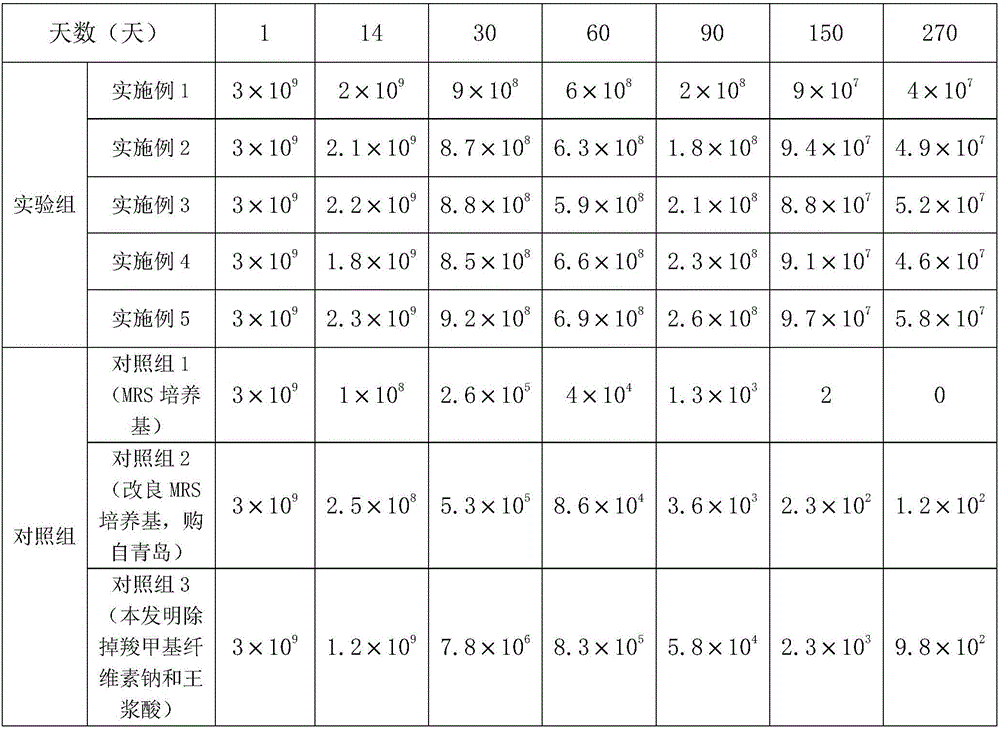

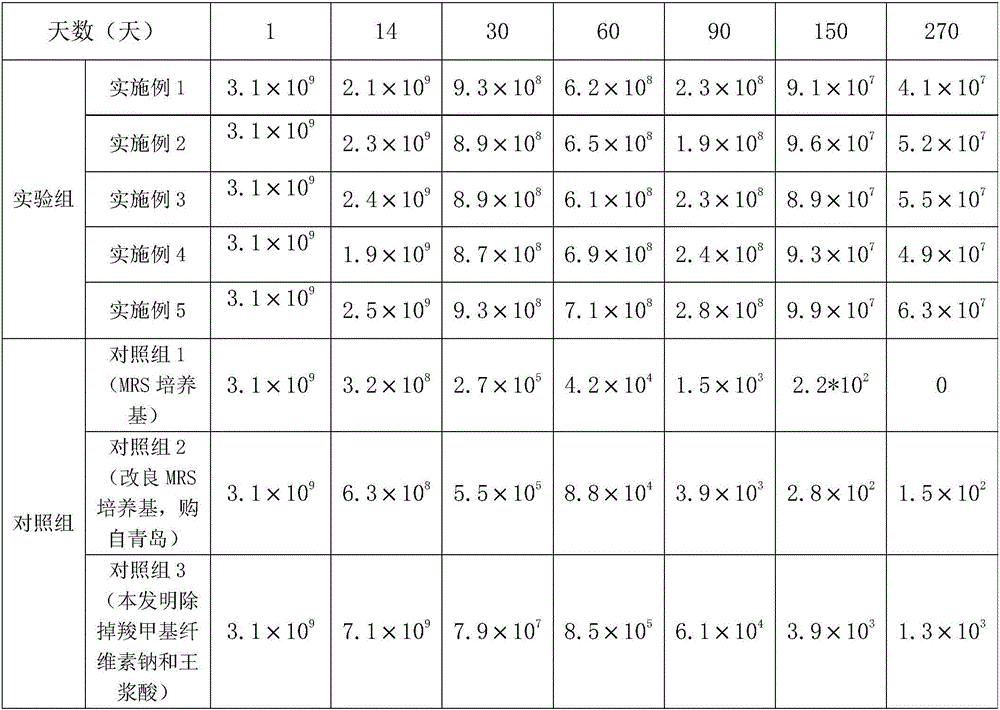

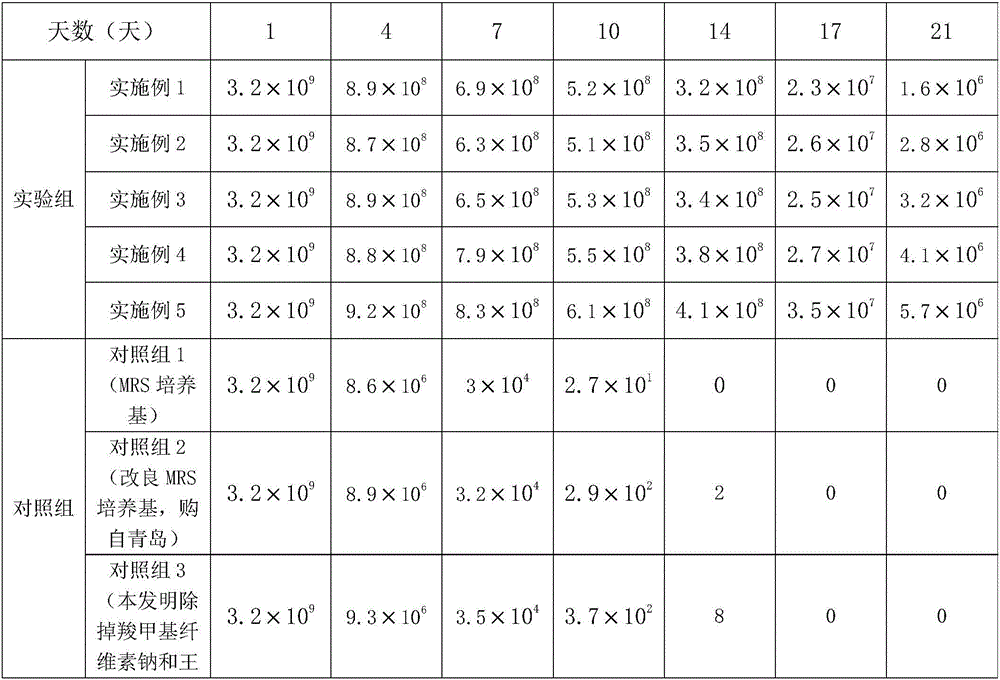

Examples

Embodiment 1

[0038] Embodiment 1: The culture medium that effectively prolongs the survival period of lactic acid bacteria is prepared from the following raw materials in parts by weight (30 g per part): 0.08 part of peptone, 0.08 part of yeast extract powder, 1.5 part of manno-oligosaccharide, skimmed milk powder 0.8 parts, 0.5 parts of defatted soybean meal, 0.05 parts of magnesium sulfate heptahydrate, 0.025 parts of manganese sulfate heptahydrate, 1.5 parts of corn steep liquor dry powder, 0.008 parts of compound additives, 0.025 parts of sodium dihydrogen phosphate, 0.25 parts of sodium citrate, 0.2 parts of citric acid , 0.08 part of sodium acetate, 0.08 part of Tween 80, 0.04 part of saccharomyces cerevisiae; the composite additive is a mixture of sodium carboxymethyl cellulose, sodium alginate, bone powder, royal jelly acid, guar gum and xanthan gum, And the mass ratio is sodium carboxymethyl cellulose: sodium alginate: bone meal: royal jelly acid: guar gum: xanthan gum=2:2:3:1:1:2;...

Embodiment 2

[0047] Embodiment 2: The substratum that effectively prolongs the survival period of lactic acid bacteria, its active ingredient is made of the raw materials of following weight (every part gets 15g): 0.12 parts of peptone, 0.12 parts of yeast extract powder, 2.5 parts of mannan oligosaccharides, 1.2 parts of skimmed milk powder 0.7 parts of defatted soybean meal, 0.07 parts of magnesium sulfate heptahydrate, 0.035 parts of manganese sulfate heptahydrate, 2.5 parts of corn steep liquor dry powder, 0.012 parts of compound additives, 0.035 parts of sodium dihydrogen phosphate, 0.35 parts of sodium citrate, 0.3 parts of citric acid, 0.12 parts of sodium acetate, 0.12 parts of Tween 80, and 0.06 parts of Saccharomyces cerevisiae; the composite additive is a mixture of sodium carboxymethyl cellulose, sodium alginate, bone meal, royal jelly acid, guar gum and xanthan gum, and The mass ratio is sodium carboxymethyl cellulose: sodium alginate: bone meal: royal jelly acid: guar gum: xan...

Embodiment 3

[0055] Embodiment 3: the substratum that effectively prolongs the survival period of lactic acid bacteria, its active ingredient is made of the raw materials of following weight (every part gets 25kg): 0.09 part of peptone, 0.09 part of yeast extract powder, 1.8 part of mannan oligosaccharide, 0.9 part of skimmed milk powder 0.55 parts of defatted soybean meal, 0.055 parts of magnesium sulfate heptahydrate, 0.028 parts of manganese sulfate heptahydrate, 1.8 parts of corn steep liquor dry powder, 0.009 parts of compound additives, 0.028 parts of sodium dihydrogen phosphate, 0.28 parts of sodium citrate, 0.23 parts of citric acid, 0.09 part of sodium acetate, 0.09 part of Tween 80, 0.045 part of Saccharomyces cerevisiae; the compound additive is a mixture of sodium carboxymethyl cellulose, sodium alginate, bone meal, royal jelly acid, guar gum and xanthan gum, and The mass ratio is sodium carboxymethyl cellulose: sodium alginate: bone meal: royal jelly acid: guar gum: xanthan gum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com