Ultrawhite polished tile and preparation method thereof

A ceramic tile and ultra-white technology, which is applied in the field of tile production, can solve the problems of rough surface texture, insufficient smoothness, and unqualified radioactivity inspection, so as to improve whiteness, avoid cost waste, and solve the effects of radioactivity exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of ultra-white polished ceramic tiles comprises the following steps:

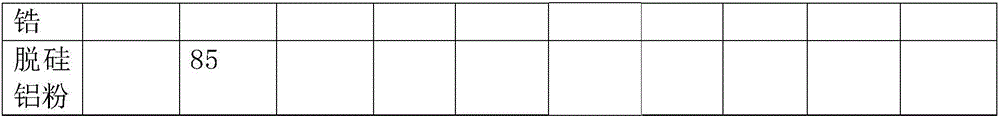

[0033] A. Raw materials: 25% of Dongxing sand, 6% of super white sand, 9% of Fuming sand, 14% of water mill powder, 15% of super white ball clay, 13% of super white powder, 6% of quartz powder, 2.6% of burnt talc, bentonite 2.5%, desiliconized aluminum powder 6%, water reducer 0.3%, water glass 0.4% and high-efficiency reinforcing agent 0.2% are mixed and prepared to obtain a mixture A1;

[0034] B. Ball milling; adding the mixture A1 and water into a ball mill for mixing and grinding, and forming slurry B1 under the condition of satisfying the fineness, moisture and viscosity of the slurry,

[0035] C, spray granulation; spray the slurry B1 in a spray drying tower to dry it and granulate to form powder C1;

[0036] D. Stamping forming; adding the powder C1 into a punching machine for cloth and punching forming, the punching speed of the punching machine is 4.2-4.5 times / min, and the...

Embodiment 2

[0040] The preparation of ultra-white polished ceramic tiles comprises the following steps:

[0041] A. Raw materials: 29% of Dongxing sand, 5% of super white sand, 8% of Fuming sand, 12% of water mill powder, 13% of super white ball clay, 20% of super white powder, 4% of quartz powder, 2.5% of calcined talc, bentonite 1.7%, 4% desiliconized aluminum powder, 0.3% water reducer, 0.3% water glass and 0.2% high-efficiency reinforcing agent are mixed and prepared to obtain a mixture A1;

[0042] B. Ball milling; adding the mixture A1 and water into a ball mill for mixing and grinding, and forming slurry B1 under the condition of satisfying the fineness, moisture and viscosity of the slurry,

[0043] C, spray granulation; spray the slurry B1 in a spray drying tower to dry it and granulate to form powder C1;

[0044] D. Stamping forming; adding the powder C1 into a punching machine for cloth and punching forming, the punching speed of the punching machine is 4.2-4.5 times / min, and ...

Embodiment 3

[0048] The preparation of ultra-white polished ceramic tiles comprises the following steps:

[0049] A. Raw materials: 25% of Dongxing sand, 7% of ultra-white sand, 10% of Fuming sand, 13% of water mill powder, 15% of ultra-white ball clay, 20% of ultra-white powder, 4% of quartz powder, 2.1% of burnt talc, silicon 3% of zirconium acid, 0.3% of water reducer, 0.4% of water glass and 0.2% of high-efficiency reinforcing agent are mixed and equipped to obtain mixture A1;

[0050] B. Ball milling; adding the mixture A1 and water into a ball mill for mixing and grinding, and forming slurry B1 under the condition of satisfying the fineness, moisture and viscosity of the slurry,

[0051] C, spray granulation; spray the slurry B1 in a spray drying tower to dry it and granulate to form powder C1;

[0052] D. Stamping forming; adding the powder C1 into a punching machine for cloth and punching forming, the punching speed of the punching machine is 4.2-4.5 times / min, and the punching pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com