High-performance cement and its preparation method

A high-performance, cement technology, applied in the field of building materials, can solve the problems of occupation, more land, hindering the development and application of new nickel-iron technology in factories, etc., and achieve the functions of reducing product cost, high viscosity, wrapping and supporting strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

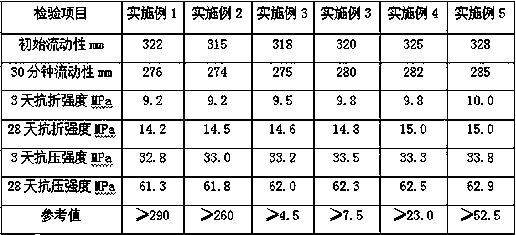

Examples

Embodiment 1

[0024] Mix 40 parts of sulphoaluminate cement clinker, 5 parts of submerged arc furnace granulated slag fine powder, and 1 part of calcined coal gangue fine powder according to the set weight ratio, and put them into a cement mill to grind them until the specific surface area is >450m 2 / kg, then add 0.1 part of early strength agent, 0.1 part of water reducer, 0.01 part of air-entraining agent and 0.1 part of dispersant to the cement mill by weight ratio, and the mixed material from the grinding head of the cement mill is used The hoist transports the finished product into the homogenization bin, and the high-performance cement is obtained after homogenization by the air generated at the bottom of the homogenization bin.

Embodiment 2

[0026] Mix 42 parts of sulfoaluminate cement clinker, 56 parts of submerged arc furnace granulated slag fine powder, and 1.5 parts of calcined coal gangue fine powder according to the set weight ratio, and put them into a cement mill to grind them until the specific surface area is >450m 2 / kg, then add 0.5 parts of early strength agent, 0.2 parts of water reducer, 0.02 parts of air-entraining agent and 0.1-0.5 parts of dispersant into the cement mill according to the weight ratio, and the mixed material coming out of the grinding head of the cement mill , transported into the finished product homogenization bin by a hoist, and the high-performance cement can be obtained after homogenization by the air generated at the bottom of the homogenization bin.

Embodiment 3

[0028] Mix 46 parts of sulphoaluminate cement clinker, 7 parts of submerged arc furnace granulated slag fine powder, and 2 parts of calcined coal gangue fine powder according to the set weight ratio, and put them into a cement mill to grind them until the specific surface area is >450m 2 / kg, then add 1.0 part of early strength agent, 0.3 part of water reducing agent, 0.03 part of air-entraining agent and 0.1-0.5 part of dispersant into the cement mill according to the weight ratio, and the mixed material coming out of the grinding head of the cement mill , transported into the finished product homogenization bin by a hoist, and the high-performance cement can be obtained after homogenization by the air generated at the bottom of the homogenization bin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com