Method for producing methane through anaerobic digestion of high-solid content sludge

An anaerobic digestion, high solid content technology, applied in biological sludge treatment, waste fuel and other directions, can solve the problems of low volume load and low gas production efficiency of sludge anaerobic digestion, and improve sludge resource utilization and efficiency. The degree of energy utilization, increasing efficiency, and the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

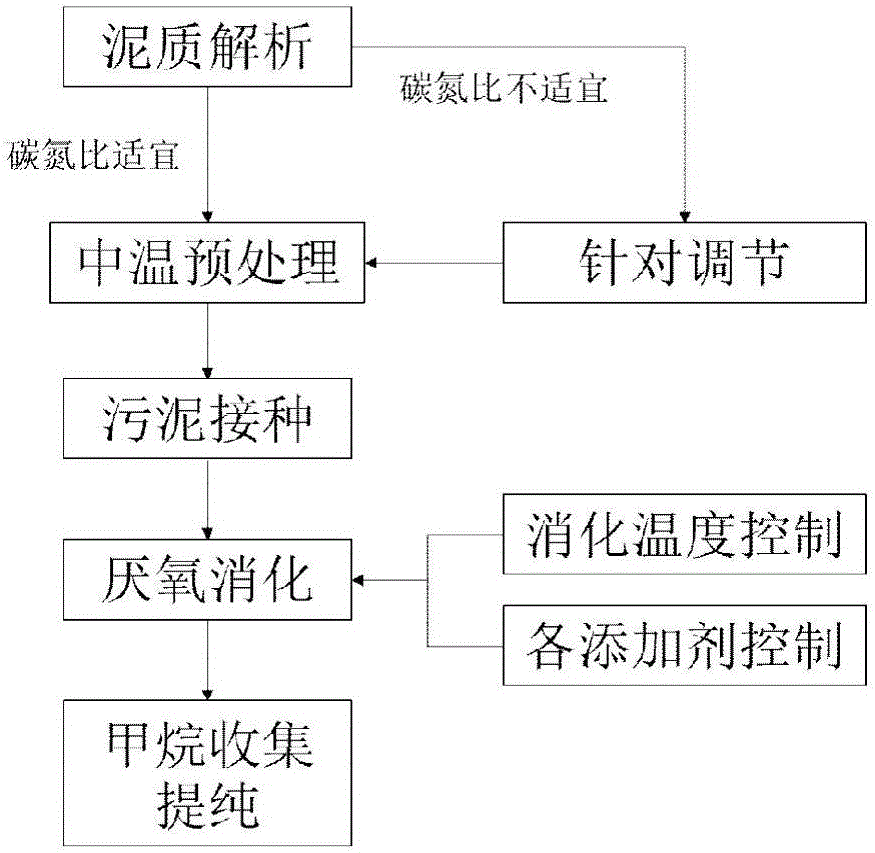

[0030] Such as figure 1 As shown, the sludge dehydrated by a belt filter press was taken from an urban sewage treatment plant, with a solid content of 12%, and an anaerobic digestion experiment was carried out.

[0031] Step 1: The carbon-nitrogen ratio of the sludge is measured as 22 according to the standard method of TOC measuring instrument and soil total nitrogen measurement, which is within a suitable range, so no additional carbon-nitrogen ratio regulator is added.

[0032] Step 2. Since the experiment was in summer and the average daytime temperature was about 37°C, the sludge to be digested was sealed and kept at room temperature for one day. The inoculum sludge comes from the hydrolytic acidification tank of the urban sewage treatment plant, and the SS is 14g / L after sedimentation and concentration. Take 800mL dewatered sludge, add 200mL inoculated sludge, and mix.

[0033] Step 3, add rhamnolipid 1g, alkyl polyglycoside 0.1g, TCS 1mg to the mixed sludge, then add ...

Embodiment 2

[0036] The sludge dehydrated by centrifuge was taken from a city sewage treatment plant, with a solid content of 16%, and an anaerobic digestion experiment was carried out.

[0037] Step 1. Measure the carbon-nitrogen ratio of the sludge according to the TOC measuring instrument and the standard method of soil total nitrogen measurement to be 15. Take the broken kitchen waste from a staff canteen, and measure its carbon-nitrogen ratio by the same method. The ratio is mixed with the sludge to be digested, so that the carbon-nitrogen ratio is 20, and it is ready for use.

[0038] Step 2: Place the sludge to be digested in a sealed oven at 37°C, and treat it at a constant temperature for one day. The inoculum sludge comes from the hydrolytic acidification tank of an urban sewage treatment plant, and the SS is 12g / L after sedimentation and concentration. Take 4L of dewatered sludge, add 1L of inoculated sludge, and mix.

[0039] Step 3, add rhamnolipid 15g, alkyl polyglycoside 1...

Embodiment 3

[0042]The sludge dehydrated by a centrifuge was taken from the sewage treatment section of a pharmaceutical factory, with a solid content of 14%, and an anaerobic digestion experiment was carried out.

[0043] Step 1. Measure the carbon-nitrogen ratio of the sludge according to the standard method of TOC measuring instrument and soil total nitrogen measurement to be 8, take the kitchen waste after being smashed from a staff canteen, measure its carbon-nitrogen ratio by the same method, and then calculate and press The ratio is mixed with the sludge to be digested, so that the carbon-nitrogen ratio is 40, and it is set aside.

[0044] Step 2: Place the sludge to be digested in a sealed oven at 37°C, and treat it at a constant temperature for 0.5 days. The inoculum sludge comes from the hydrolytic acidification tank of an urban sewage treatment plant, and the SS is 16g / L after sedimentation and concentration. Take 3.3L dewatered sludge, add 1.7L inoculated sludge, and mix.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com