Lead and zinc industrial wastewater treatment device and method

A technology for industrial waste water and treatment equipment, which is applied in mining waste water treatment, metallurgical waste water treatment, multi-stage water treatment, etc. It can solve the problems of high energy consumption, high cleaning cost, large circulation flow and circulation pressure, and achieve low energy consumption. , low cleaning cost and stable membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

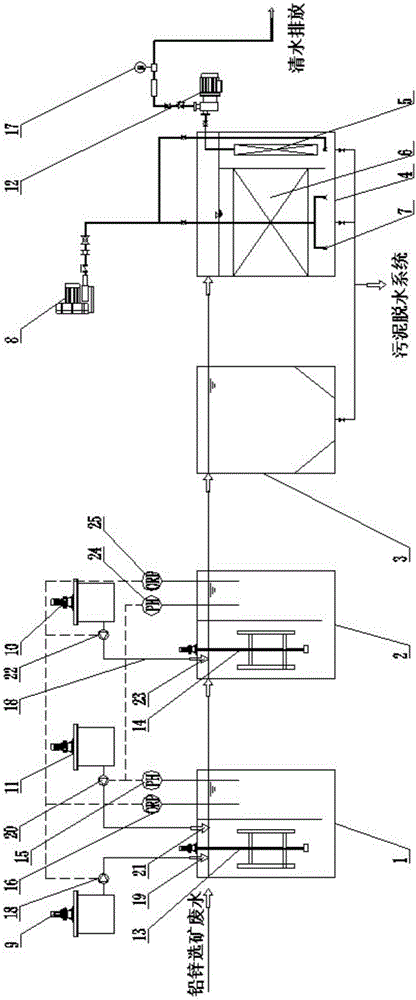

Method used

Image

Examples

Embodiment 1

[0074] Wastewater discharged from a lead-zinc beneficiation plant contains harmful components such as copper, lead, zinc, selenium, arsenic, organic matter, and ammonia nitrogen.

[0075] The beneficiation wastewater is lifted to the primary reaction pool by a corrosion-resistant self-priming pump, and sodium hydroxide is added to pre-adjust the pH to 8.0-9.0, and sodium sulfide is added at a ratio of 120 mg / L, and the reaction is stirred for 1 hour.

[0076] Enter the secondary reaction pool, add ferrous sulfate according to the ratio of 160mg / L, and stir for 1h.

[0077] Enter the primary sedimentation tank for solid-liquid separation, and the supernatant is discharged into the double-membrane treatment tank.

[0078] The self-priming pump is used to extract the treated clean water, the flow rate of the effluent is the same as that of the water to be treated, the head is less than 10m, the energy consumption is low, and the pH value of the effluent is 7.2.

[0079] The slud...

Embodiment 2

[0091] A lead-zinc metal smelting enterprise discharges smelting wastewater and a small amount of domestic sewage, which contains organic matter, ammonia nitrogen, lead, zinc, arsenic, cadmium and other pollutants that exceed the discharge standard. The wastewater is acidic, with a pH value of 4-7.

[0092] Adopt the test device of embodiment 1 to process, and the treatment water volume is 6 tons / day.

[0093] Lead-zinc industrial smelting wastewater is lifted to the primary reaction pool of the treatment device by an acid-resistant pump, and calcium hydroxide is added to pre-adjust the pH to 8.0-9.0, and sodium sulfide is added at a ratio of 160 mg / L, and the reaction is stirred for 1.5 hours.

[0094] Enter the secondary reaction tank, add ferrous sulfate according to the ratio of 220mg / L, and stir for 1.5h.

[0095] Enter the primary sedimentation tank for solid-liquid separation, and the supernatant is discharged into the double-membrane treatment tank.

[0096] The self-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com