Plasma water processing system

A water treatment system, plasma technology, applied in the direction of plasma, light water/sewage treatment, electrical components, etc., can solve the problems of cumbersome maintenance, high cost, complexity, etc., achieve broad application prospects, reduce environmental damage, temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

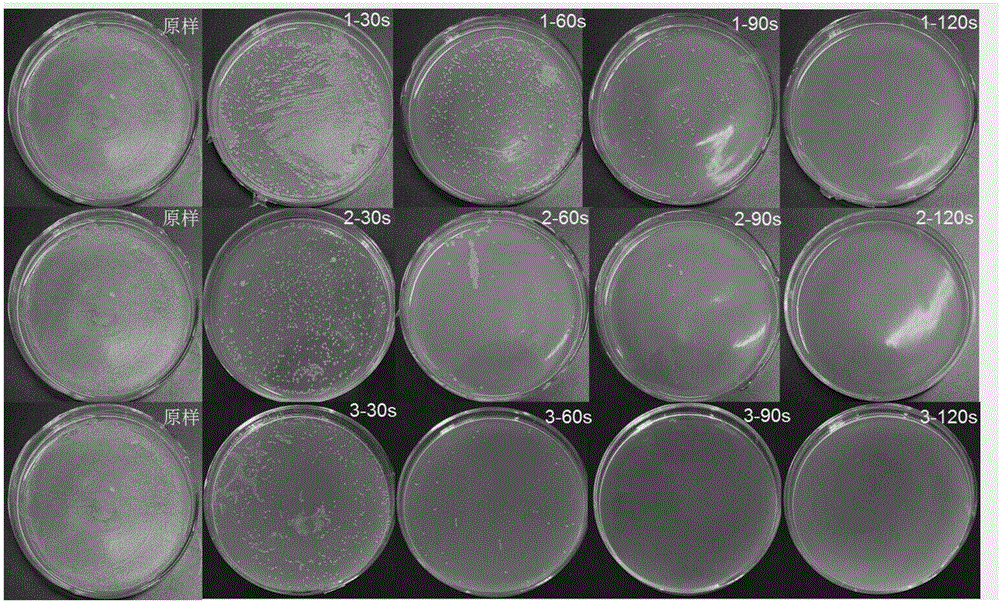

Image

Examples

Embodiment 1

[0032] Such as figure 1As shown, the first cavity of the dielectric box is a cube structure with a length, width and height of 1100mm, and a wall thickness of 100mm, forming a hollow cavity with a side length of 900mm, and the cavity is made of polytetrafluoroethylene. The distance between the water inlet pipe and the upper surface of the cavity is 200mm, and the distance between the water outlet pipe and the upper surface of the chamber is 230mm. The outer diameter of the water inlet and outlet pipes is 300mm, the wall thickness is 50mm, and the inner diameter is 200mm. , The outlet pipe is made of quartz material. Both the first PCB board and the second PCB board are in the shape of a cuboid with a length of 1100mm, a width of 300mm, and a thickness of 10mm. A gasket is adhered between the PCB board and the cavity of the dielectric body. The thickness of the gasket is 5mm to ensure that the first PCB board and the second PCB board The vertical distance between the average P...

Embodiment 2

[0034] Such as image 3 As shown, the first cavity of the dielectric box is a rectangular parallelepiped structure with a length and width of 200mm, a height of 500mm, and a wall thickness of 25mm, forming a hollow cavity of 150mm*150mcm*450mm. The cavity is made of plexiglass. The distance between the water inlet pipe and the upper surface of the cavity is 50mm, and the distance between the water outlet pipe and the upper surface of the chamber is 200mm. The outer diameter of the water inlet and outlet pipes is 100mm, the wall thickness is 15mm, and the inner diameter is 70mm. , The outlet pipe is made of corrosion-resistant plastic. Both the first PCB board and the second PCB board are in the shape of a cuboid with a length of 500mm, a width of 50mm, and a thickness of 2mm. A gasket is adhered between the PCB board and the cavity of the dielectric body. The thickness of the gasket is 1mm to ensure that the first PCB board and the second PCB board The vertical distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com