A robot control system

A control system and robot technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of inflexibility, single control method, low efficiency, etc., to achieve the effect of simplifying the control system, improving the cost performance, and free and flexible control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

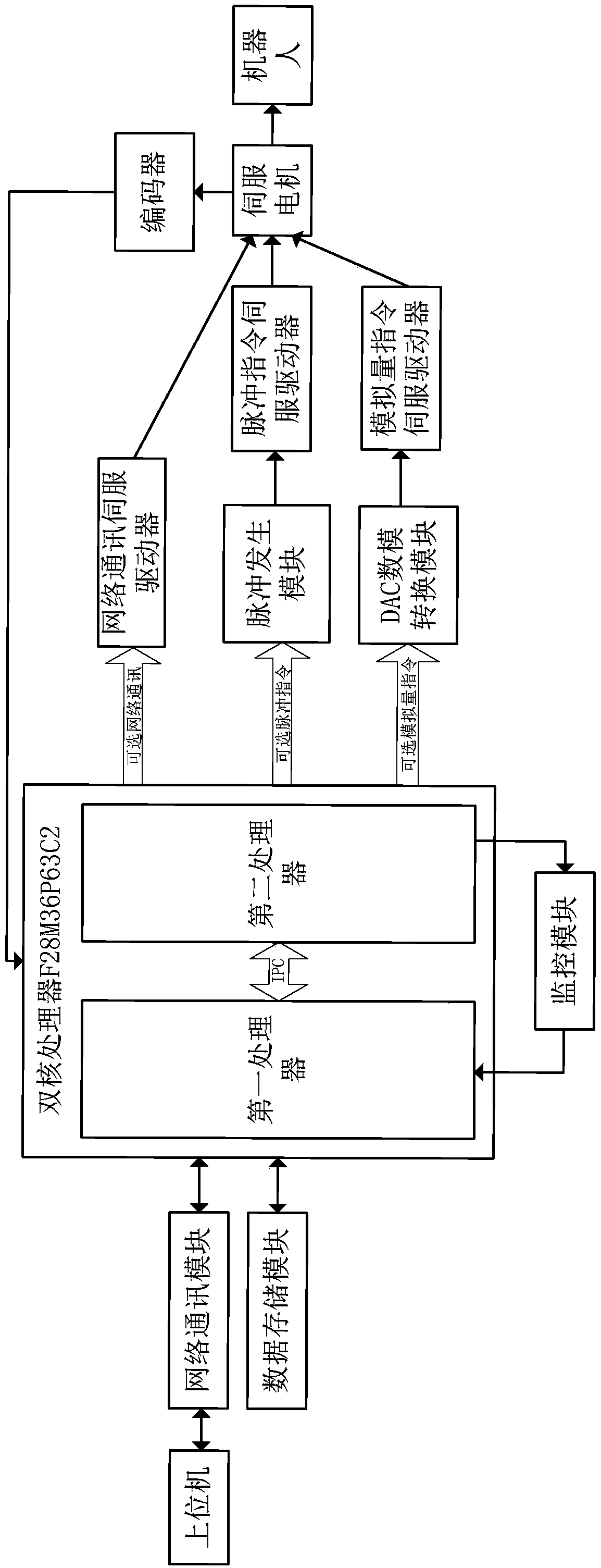

[0039] Such as figure 1 As shown, the present invention provides a kind of robot control system, comprises dual-core processor, and dual-core processor is respectively connected with network communication module, data storage module, monitoring module, network communication servo driver, pulse generation module, DAC digital-to-analog conversion module; The communication module is connected with the host computer; the pulse generation module is connected with the pulse command servo driver; the DAC digital-to-analog conversion module is connected with the analog command servo driver; the network communication servo driver is connected with the servo motor; the servo motor is also connected with the pulse command servo driver, analog Quantity command servo drive, robot, encoder connection; also includes power management module.

[0040] The power management module is used to provide power to the control system. The power management module is a low-voltage power supply. The power...

Embodiment 2

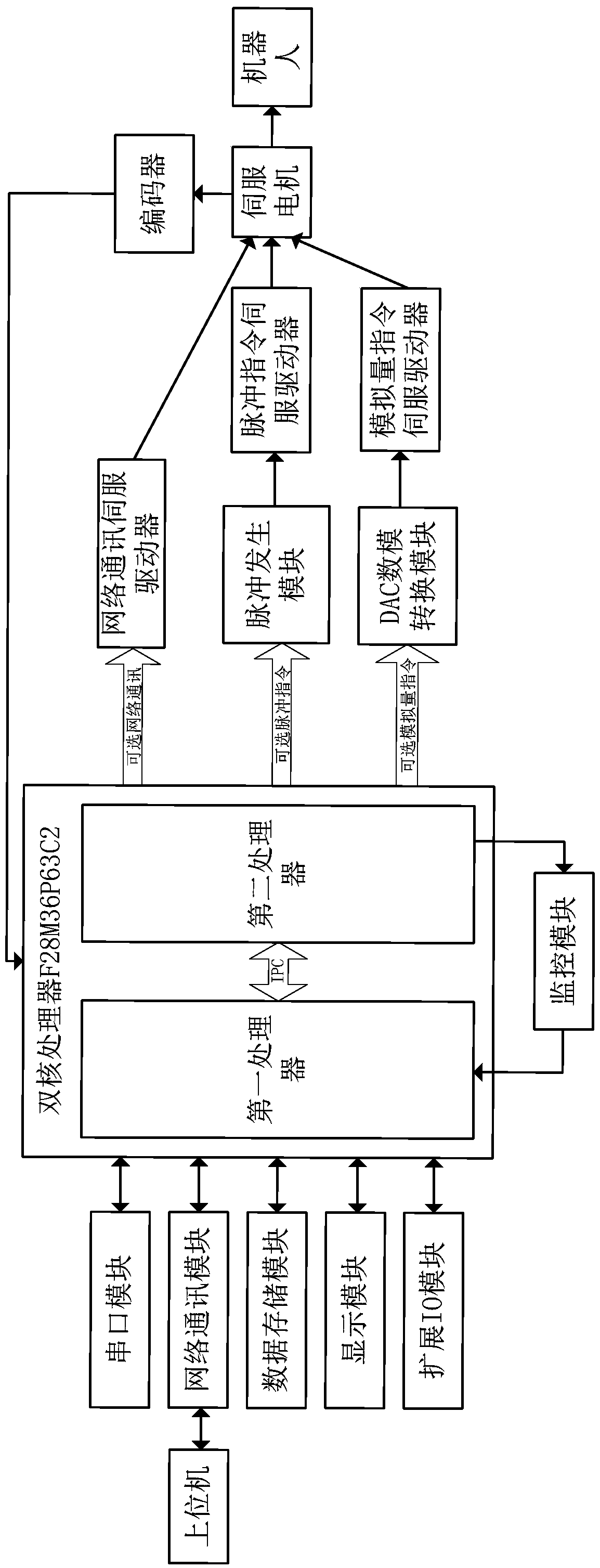

[0054] Such as figure 2 As shown, the present invention also provides a robot control system described in the robot control system, which also includes a serial port module connected to the dual-core processor on the basis of Embodiment 1, and the serial port module is used for the expansion interface of the serial communication mode Realize the connection between the control system and external equipment.

[0055] The robot control system also includes a display module connected with the dual-core processor, and the display module is used for displaying state data reflecting the control system.

[0056] The robot control system also includes an extended IO module connected to the dual-core processor, and the extended IO module is used for data analysis or exchange between the control system and external devices.

[0057] Compared with the prior art, the beneficial effects of the present invention are as follows:

[0058] 1), the present invention adopts ARM as peripheral c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com