Repair method of cold-rolled support roller

A repair method and backup roll technology, applied in the field of cold-rolled backup rolls, to achieve the effects of good bonding, improved wear resistance, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

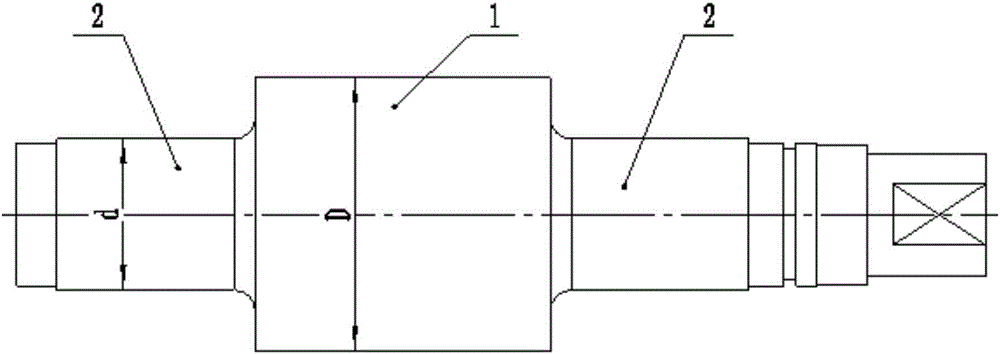

[0047] This embodiment provides a method for repairing cold-rolled back-up rolls, and the repaired cold-rolled back-up rolls are as figure 1 As shown, its material is 9Cr 2 Mo, the original working diameter D of back-up roll matrix 1 = 650mm, the diameter d of roll neck 2 = 360mm, the specific operation steps are:

[0048] 1. Cleaning and flaw detection treatment

[0049] First use gasoline to clean the back-up roll to be repaired, remove surface oil and impurities, and wipe it clean; then carry out coloring inspection on the roll neck 2 of the back-up roll, if cracks are found on the roll neck 2, the back-up roll is scrapped and cannot be repaired. Because the roll neck 2 is the position where the backup roll installs the bearing, it is the supporting part, which directly affects the working performance and safety of the backup roll. In addition, as the working time continues, the cracks will slowly expand to the surroundings, not only the stability of the back-up roll will...

Embodiment 2

[0064] This embodiment provides a repair method for cold-rolled back-up rolls, the repaired cold-rolled back-up rolls such as figure 1 As shown, its material is 9Cr 2 Mo, the original working diameter of back-up roll matrix 1 is D=700mm, and the diameter of roll neck 2 is d=380mm. The specific operation steps are:

[0065] 1. Cleaning and flaw detection treatment

[0066] First use gasoline to clean the back-up roll to be repaired, remove surface oil and impurities, and wipe it clean; then carry out coloring inspection on the roll neck 2 of the back-up roll, and no cracks are found, then observe and mark the cracks visible to the naked eye on the surface of the back-up roll base 1, mark There are 4 places, and then use HANWEI HS606 ultrasonic flaw detector to detect flaws on the surface of backup roll base 1, mark cracks that cannot be recognized by naked eyes, so as to avoid that all cracks cannot be removed during subsequent cutting, and 2 places are found and marked. Ther...

Embodiment 3

[0081] This embodiment provides a method for repairing cold-rolled back-up rolls, and the repaired cold-rolled back-up rolls are as figure 1 As shown, its material is 9Cr 2 Mo, the original working diameter D of back-up roll matrix 1 = 750 mm, the diameter d of roll neck 2 = 400 mm, the specific operation steps are:

[0082] 1. Cleaning and flaw detection treatment

[0083] First use gasoline to clean the back-up roll to be repaired, remove surface oil and impurities, and wipe it clean; then carry out coloring inspection on the roll neck 2 of the back-up roll, and no cracks are found, then observe and mark the cracks visible to the naked eye on the surface of the back-up roll base 1, mark There are 2 places, and then use HANWEI HS606 ultrasonic flaw detector to detect flaws on the surface of backup roller base 1, mark cracks that cannot be recognized by naked eyes, so as to avoid that all cracks cannot be removed during subsequent cutting, and 5 places are found and marked. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com