Automatic flocculant solution preparing and quantitative adding system for sugar refinery and operating method thereof

An automatic preparation and operation method technology, which is applied in chemical instruments and methods, dissolution, sucrose production, etc., can solve the problems that the metering pump speed cannot be adjusted constantly, it is difficult to achieve the effect of flocculant, and the flow rate of sugar juice is low, so as to achieve low cost, Easy to implement and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

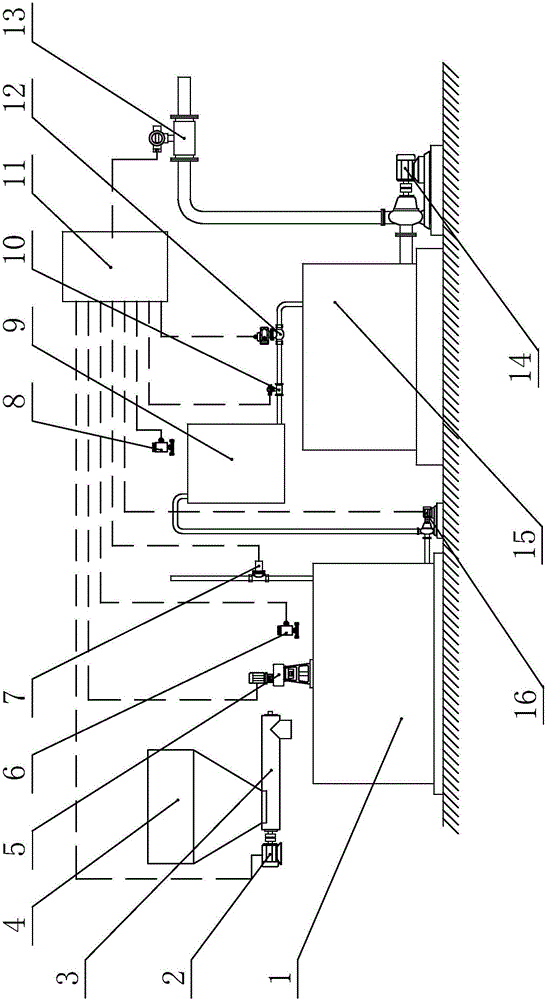

[0044] Example of automatic preparation and quantitative addition system of flocculant solution in sugar factory

[0045] Example of automatic preparation and quantitative addition system of flocculant solution in this sugar factory figure 1 As shown, it includes a storage box 4 for storing flocculant powder, a flocculant proportioning box 2, a flocculant temporary storage box 9 and a sugar juice temporary storage box 15; the water pipe is connected to the flocculant proportioning box 1, and a matching The specific water valve 7 and the flocculant storage box 4 are connected to the flocculant proportioning box 1 through the quantitative feeding device. The quantitative feeding device of the flocculant storage box 4 in this example is a screw conveyor, and the screw conveyor includes a screw conveyor motor 2 and the spiral conveying groove 3, there is a spiral conveying rod in the spiral conveying groove 3, the spiral conveying motor 2 is connected to drive the spiral conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com