Steam condensate heat exchange system with automatic dosing device

A technology of automatic dosing and dosing device, which is applied in the field of steam condensate heat exchange system, can solve the problems of different flow directions of medicine, complicated control, and the inability to add medicine to the heat exchanger, so as to achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

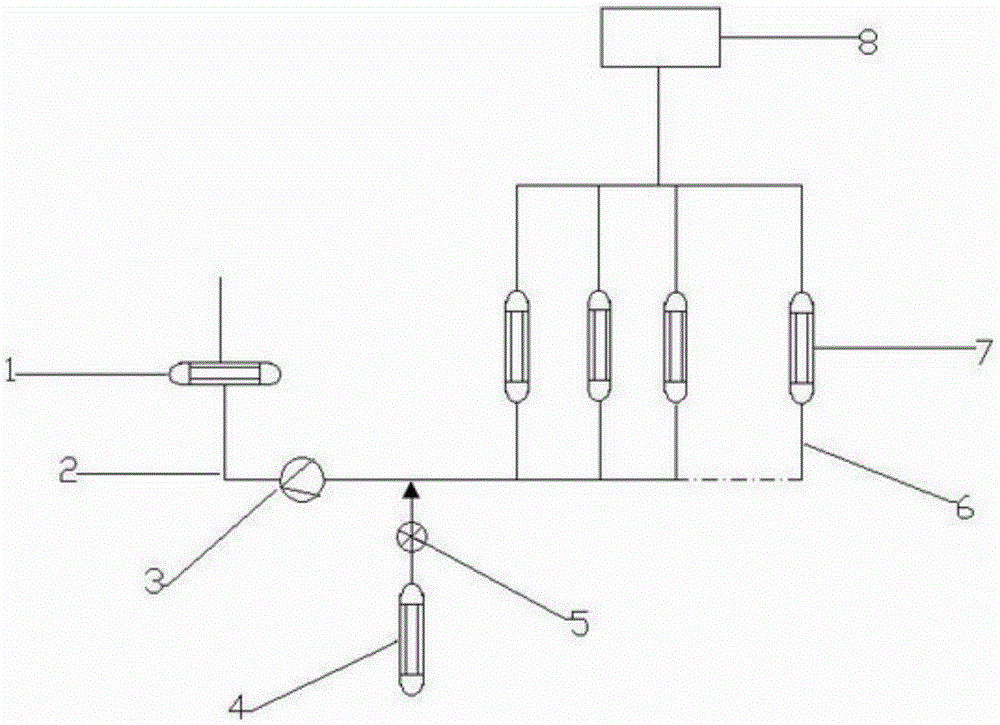

[0023] Such as figure 1 A steam condensate system with an automatic dosing device is shown, including a condenser 1, a condensate main pipe 2, a pump 3, a dosing device 4, a control valve 5, a condensate branch pipe 6 and a heat exchanger 7;

[0024] One end of the condensate main pipe 2 is provided with a steam inlet, and from the steam inlet, the condensate main pipe 2 communicates with the condenser 1 and the pump 3 successively, and the condensate main pipe 2 connected to the water outlet of the pump 3 is in parallel with a group of The condensate branch pipe 6 is connected, and the condensate branch pipe 6 is connected with a heat exchanger 7, and the terminals of the condensate branch pipe 6 are connected to each other, and are connected to the user end 8 through a connecting pipe;

[0025] The set of parallel condensate branch pipes 6 includes at least two condensate branch pipes;

[0026] The condensate main pipe 2 connected to the water outlet of the pump 3 is connec...

Embodiment 2

[0036] A steam recovery system, including a condenser 1, a condensate main pipe 2, a pump 3, a dosing device 4, a control valve 5, a condensate branch pipe 6 and a heat exchanger 7;

[0037] One end of the condensate main pipe 2 is provided with a steam inlet, and from the steam inlet, the condensate main pipe 2 communicates with the condenser 1 and the pump 3 successively, and the condensate main pipe 2 connected to the water outlet of the pump 3 is in parallel with a group of The condensate branch pipe 6 is connected, and the condensate branch pipe 6 is connected with a heat exchanger 7, and the terminals of the condensate branch pipe 6 are connected to each other, and are connected to the user end 8 through a connecting pipe;

[0038] The set of parallel condensate branch pipes 6 includes at least two condensate branch pipes;

[0039] The condensate main pipe 2 connected to the water outlet of the pump 3 is connected to the dosing device 4 through a connecting pipe.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com