Arrangement in a gearbox

A technology for transmission and transmission oil, applied in the direction of gear lubrication/cooling, clutch, belt/chain/gear, etc., can solve the problems of deterioration of lubrication and cooling, increase of fuel consumption, etc. The effect of noise volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

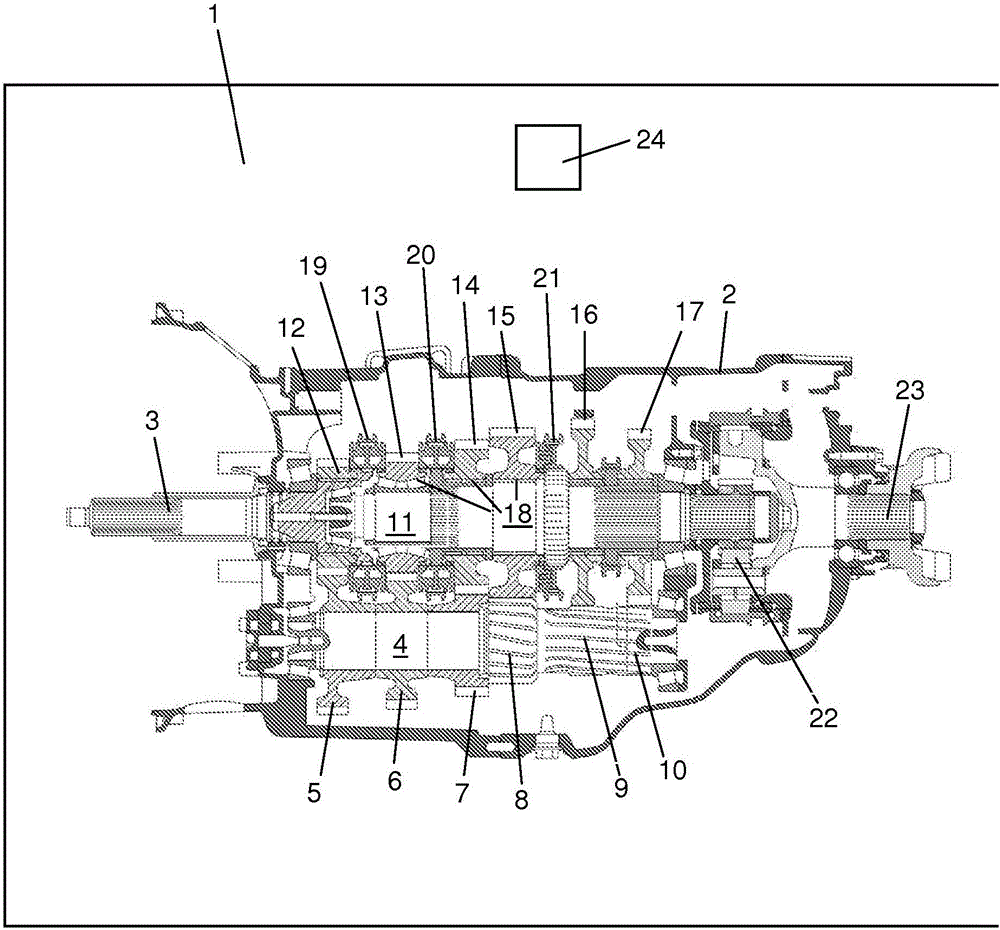

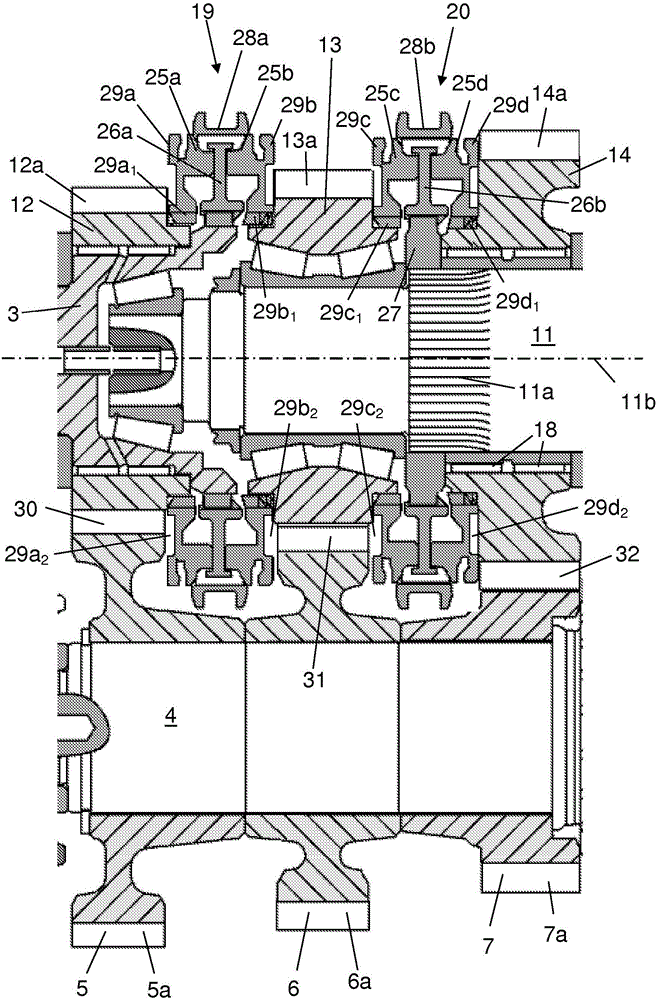

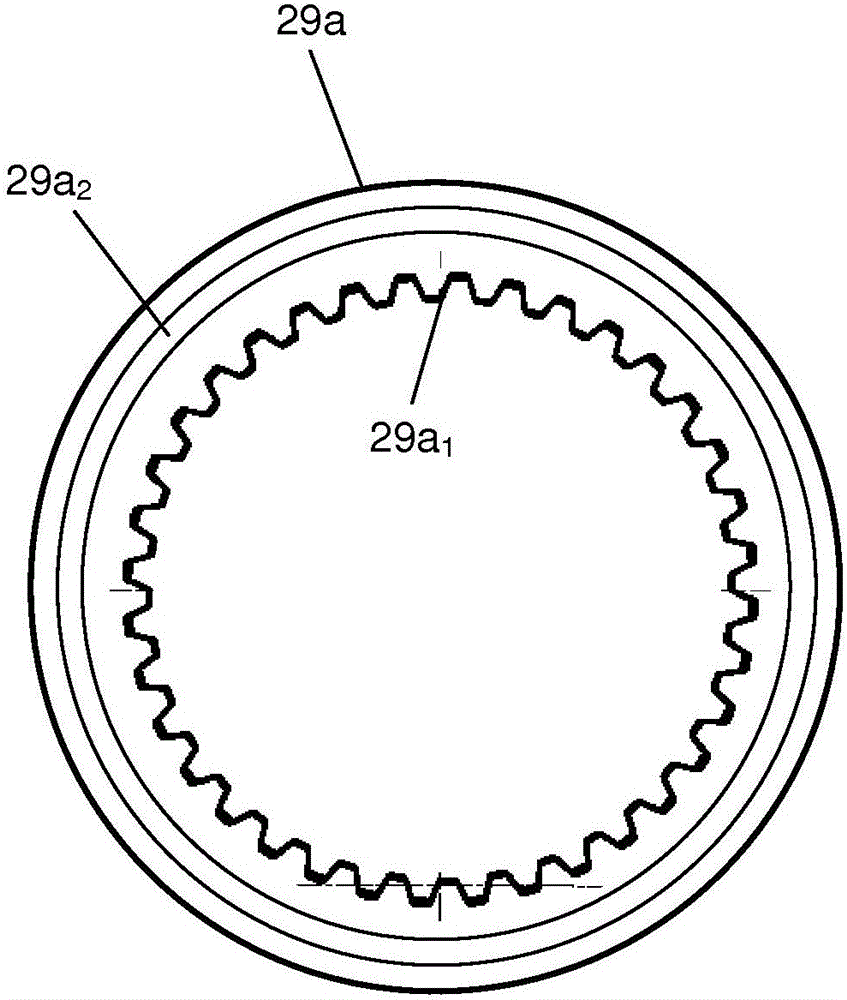

[0016] figure 1 A gearbox is shown, which can be provided in the schematically drawn vehicle 1 . Vehicle 1 may be a heavy goods vehicle. The gearbox is attached inside the housing 2, which contains the gearbox oil. The gearbox includes an input shaft 3 operated by a combustion engine, not shown. The gearbox comprises an intermediate shaft 4 equipped with a number of gears 5-10 of various sizes. The gears 5 - 10 are separate units fixedly fitted on the intermediate shaft 4 or constituting the same part of the intermediate shaft 4 . The gearbox comprises a main shaft 11 equipped with a number of gears 12-17 of various sizes. Each of the gear sets comprises a main gear 5-10 fixedly arranged on the intermediate shaft 4 and a pinion 12-17 rotatably arranged on the main shaft 11 or the input shaft 3 . The transmission is equipped with a release gear which, in a first disengaged state, connects the input shaft 3 via the first gear set 5 , 12 to the side countershaft 4 . In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com