Metal shell of communication equipment and preparation method thereof

A technology for metal casings and communication equipment, applied in metal casings, antennas, electrical components, etc., can solve problems such as damage to the metal texture, damage to the overall structure of the metal mobile phone body, and affect the overall cleanliness and continuity of the appearance. Neat, smooth and consistent, improving hardness and obvious effect of metal texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

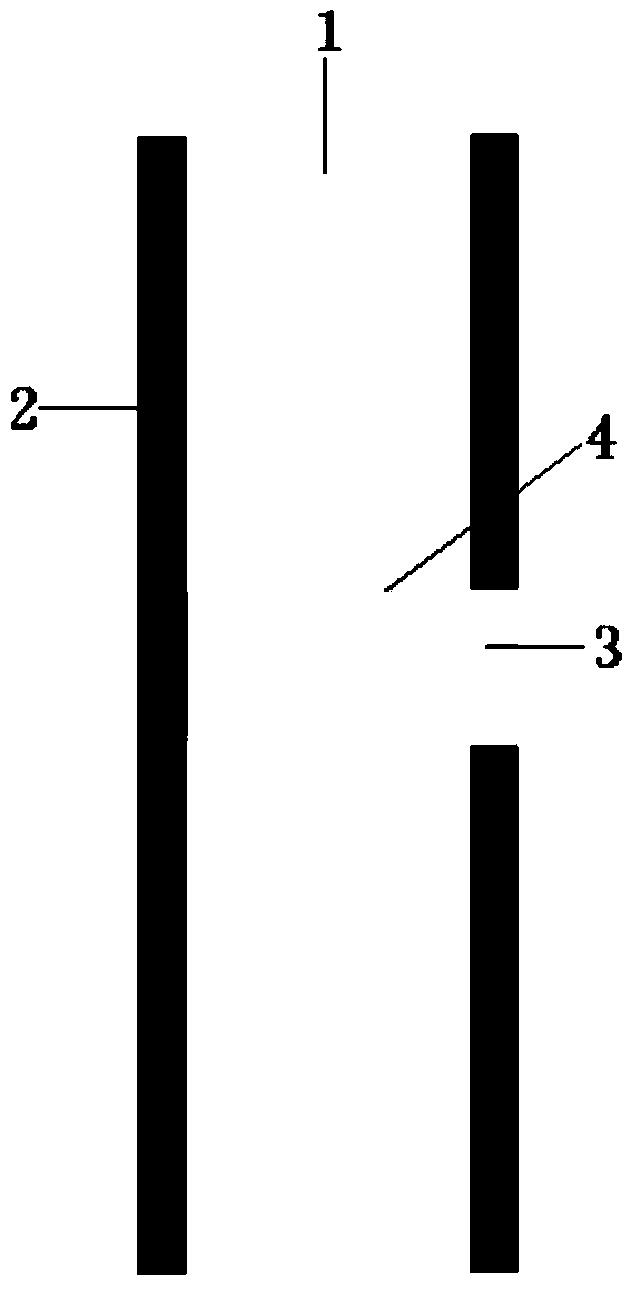

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing the metal casing of the above-mentioned communication device, wherein the method includes the following steps:

[0040] 1) A step of forming a decorative layer on the surface of the metal substrate by one or more of electrophoresis, common anodizing, porcelain anodizing, micro-arc oxidation and spraying;

[0041] 2) a step of forming a UV ink layer on the decorative layer positioned on the surface of the metal substrate;

[0042] 3) forming more than one slit on the decorative layer and the UV ink layer positioned on the inner surface side of the metal substrate to expose the metal on the inner surface of the metal substrate;

[0043] 4) Etching the metal substrate obtained in step 3) to form a slit through the metal substrate on the metal substrate;

[0044] 5) the step of removing the UV ink layer on the surface of the metal substrate;

[0045] 6) A step of filling and curing glue in the slit of the metal su...

Embodiment 1

[0083] 1) Form a decorative layer

[0084] An aluminum alloy (purchased from Dongguan Gangxiang Metal Materials Co., Ltd., grade 6063, thickness 0.4 mm) was cut into a size of 15 mm×80 mm as the metal substrate.

[0085] At 50°C, the metal substrate was etched in alkaline etching solution (60g / L sodium hydroxide aqueous solution) for 2 minutes, and then washed twice with deionized water; then, at 25°C, in the light-emitting solution (25ml / After 4min in L nitric acid aqueous solution), wash twice with deionized water; then, at 25°C, polish in chemical polishing solution (a solution consisting of 650ml / L phosphoric acid and 350ml / L sulfuric acid) for 20s, then use Rinse twice with deionized water; then dry at 80° C. for 20 minutes to obtain a washed and dried metal substrate.

[0086] A decorative layer with a thickness of 30 μm is formed on the surface of the metal substrate by electrophoresis. The conditions of the electrophoresis are: the temperature is 30°C, the voltage is...

Embodiment 2

[0099] 1) Form a decorative layer

[0100] An aluminum alloy (purchased from Dongguan Gangxiang Metal Materials Co., Ltd., grade 6063, thickness 0.4 mm) was cut into a size of 15 mm×80 mm as the metal substrate.

[0101] At 50°C, the metal substrate was etched in alkaline etching solution (60g / L sodium hydroxide aqueous solution) for 2 minutes, and then washed twice with deionized water; then, at 25°C, in the light-emitting solution (25ml / After 4min in L nitric acid aqueous solution), wash twice with deionized water; then, at 25°C, polish in chemical polishing solution (a solution consisting of 650ml / L phosphoric acid and 350ml / L sulfuric acid) for 20s, then use Rinse twice with deionized water; then dry at 80° C. for 20 minutes to obtain a washed and dried metal substrate.

[0102] A decorative layer with a thickness of 20 μm was obtained by anodizing. Wherein, the anodic oxidation conditions are as follows: the anode voltage is 15V, the temperature is 19°C, and the oxidat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com