Hybrid surface-mounting process of double-side board

A double-sided, mounting technology, applied in the direction of assembling printed circuits with electrical components, metallurgical bonding, electrical components, etc., can solve the problems of increasing production costs, slow curing speed, low product qualification rate, etc., to achieve production efficiency and product qualification. The effect of improving the rate of production, reducing the production cost and high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

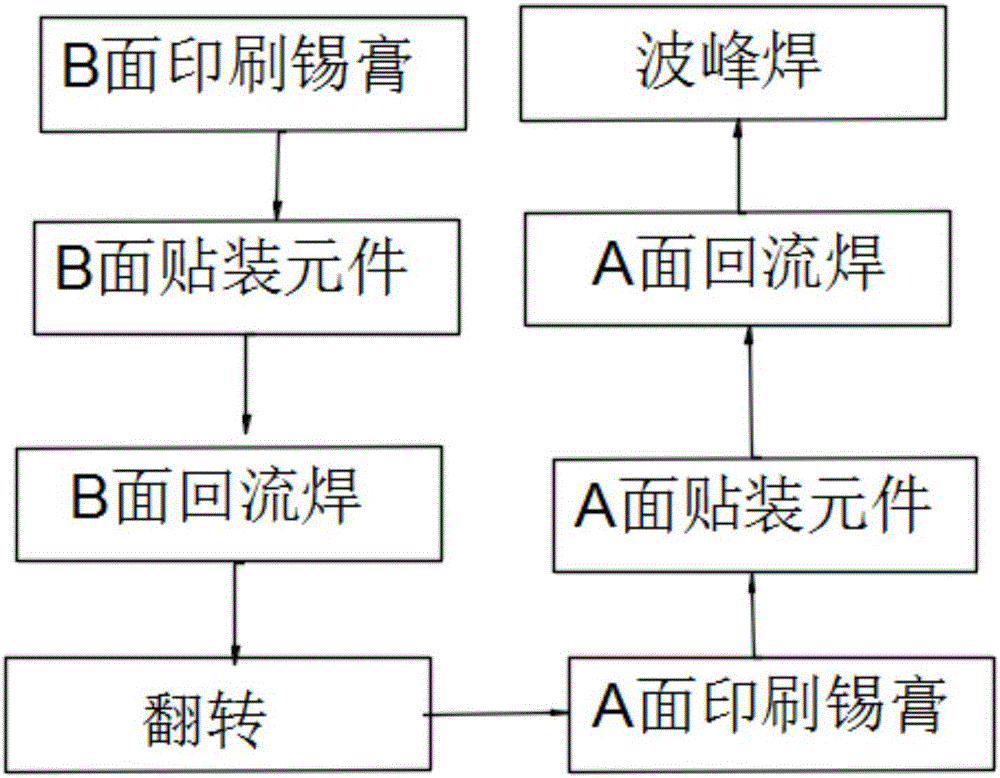

[0039] A double-sided mixed mounting process, the steps are as follows:

[0040] S1: Printing solder paste on the B side; using the stencil as the printing plate, the solder paste is printed onto the pads on the B side of the PCB board under the push of a scraper. The equipment used is a solder paste printing machine, which is located at the end of the SMT production line. front end;

[0041] S2: B surface mount components; it is to accurately install the surface mount components to the fixed position of the B surface of the PCB board. The equipment used is a placement machine, which is installed behind the printing machine in the SMT production line.

[0042] S3: B-side reflow soldering; apply a controlled amount of solder paste and solvent on the surface to be connected, then place the components in their positions, and then increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com