Hot ironing and cold ironing switching mechanism for battery cells and hot ironing and cold ironing technology for battery cells

A switching mechanism and blanching technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of space, time and cost waste, insufficient production efficiency, etc., to reduce space and cost, Improve work efficiency and overall planning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific drawings.

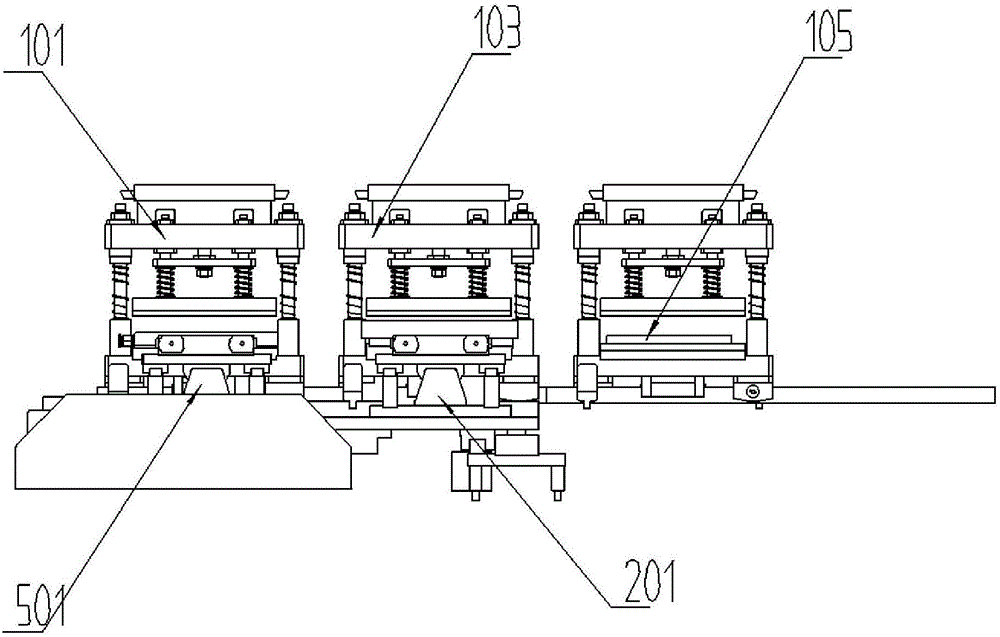

[0033] Such as Figure 1 ~ Figure 3 As shown: the electric core hot blanching and cold blanching switching mechanism includes a first jig 101, a second jig 102, a third jig 103, a fourth jig 104, an electric core 105, a first blanching cylinder 201, a first heating block 202, The second hot cylinder 401, the second heating block 402, the first cold iron cylinder 501, the first cooling block 502, the second cold iron cylinder 601, the second cooling block 602, the servo motor 301, the timing belt 302, the screw rod 303, the large Plate 304, parallel rail 305, connection block 306, guide post 307, spring 308, connection plate 309, sensor bracket 310, sensor 311, micrometer 316, stop pin 317, front rail 312, rear rail 313, initial rail 314, ball top Silk 315.

[0034] In the description of specific embodiments, with figure 1 The inward direction of the vertical paper surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com