Preparation method of ternary composite material for lead-carbon battery

A composite material and lead-carbon battery technology, which is applied in lead-acid batteries, electrical components, battery electrodes, etc., can solve the problems of graphene materials such as lower specific surface and electrical conductivity, low electrical conductivity, and easy agglomeration, so as to improve electrical conductivity Lower, lower interface resistance, solve the effect of serious agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 3g palm fiber into a 500mL Erlenmeyer flask, add 1g graphene oxide, then add 30g / L NaOH solution 400mL, at 25°C, ultrasonic treatment for 15min, then stir at 190r / min for 5h, place in Brookfield Filter in a funnel. The filtered adsorbent material was dried in a vacuum drying oven at 65 °C for 6 h, taken out, and cooled to room temperature in a desiccator to obtain graphene oxide-modified palm fiber.

[0019] Take 2g of the above-mentioned modified palm fiber and put it into a 500mL Erlenmeyer flask, add 300mL of lead nitrate solution with a concentration of 18g / L, squeeze the lid tightly, seal it with parafilm, and shake it at 190r / min for 8h at 25°C. The solid reaction product was filtered and dried under vacuum at 60 °C for 12 hours to obtain graphene oxide / biomass fibers with Pb adsorbed on the surface.

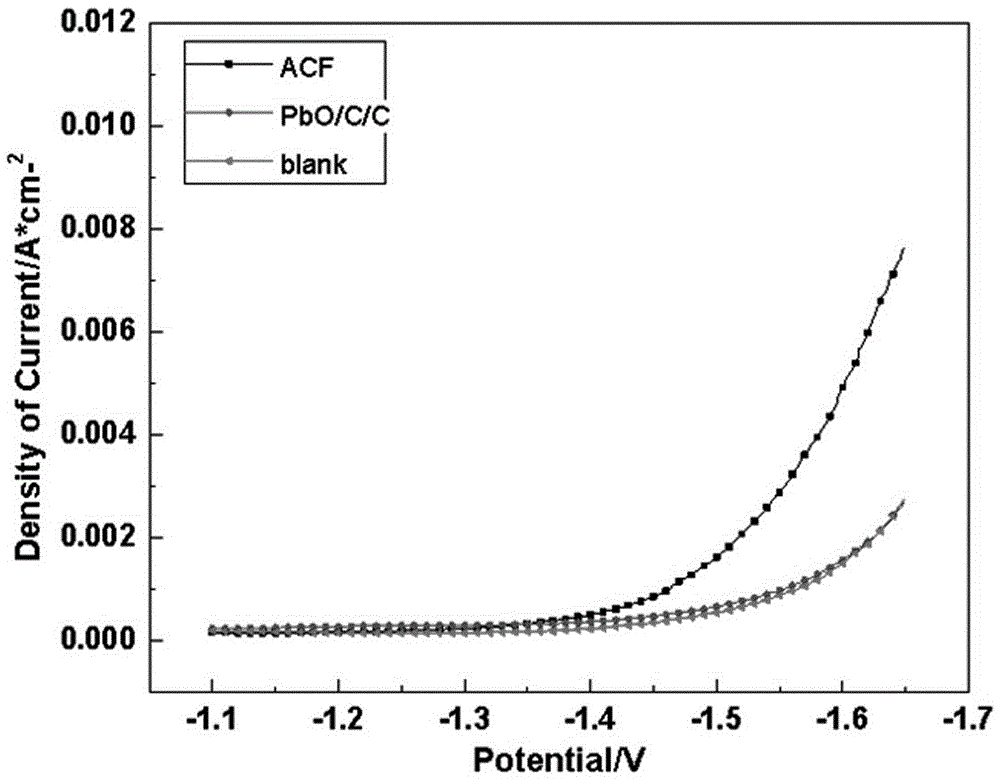

[0020] The above-mentioned biomass fibers were calcined at 800° C. for 2 hours under the protection of nitrogen, and cooled naturally to room temperature to ob...

Embodiment 2

[0022] The difference between this example and Example 1 is that sisal fiber is used as the raw material of biomass fiber, the soluble lead salt is lead chloride, and the rest are the same as Example 1.

[0023] According to the lead paste formula of positive plate: lead powder 10g, sulfuric acid 1.2g, water 1.4g, short fiber 0.02g, red lead 0.8g; negative electrode lead paste formula: lead powder 10g, sulfuric acid 1.1g, water 1.2g, short fiber 0.02 g, barium sulfate 0.2g sodium lignosulfonate 0.02g for mixing paste, the apparent density of the lead paste is controlled at 4.20g / cm 3 , and then apply the obtained lead paste on the grid to obtain positive and negative plates without activated carbon fiber.

[0024] On the basis of the above-mentioned lead paste formula, the lead / graphene / activated carbon fiber ternary composite material prepared in Example 1 was added as an additive in an amount of 0.01 g for the positive electrode and 0.02 g for the negative electrode, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com