Method for preparing metallic compound/porous carbon nanorod of hierarchy structure

A metal compound, hierarchical structure technology, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problems of unsatisfactory volume expansion reversibility, poor material cycle stability, etc., achieve excellent cycle stability, improve cycle stability, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of vanadium oxide / porous carbon nanorods of the present invention is specifically completed in the following steps:

[0039]1. Mix the vanadium chloride solution with water to prepare an inorganic salt solution with a molar concentration of 7.0mmol / L. Add 3.5mmol / L of 1,4-naphthalene dicarboxylic acid at 25°C and a stirring speed of 100-1000r / min. L, the ratio of metal inorganic salt and 1,4-naphthalene dicarboxylic acid ligand is 2:1, continue to stir for 20min, obtain the turbid solution containing metal ion complex;

[0040] 2. Transfer 30mL of the turbid liquid obtained in Step 1 to a 50mL autoclave, conduct a solvothermal reaction at 180°C for 24 hours, cool to 25°C, separate the reactant to obtain a sample, wash the sample and dry it in an oven at 60°C 6h obtains the precursor of the vanadium-based metal-organic framework complex;

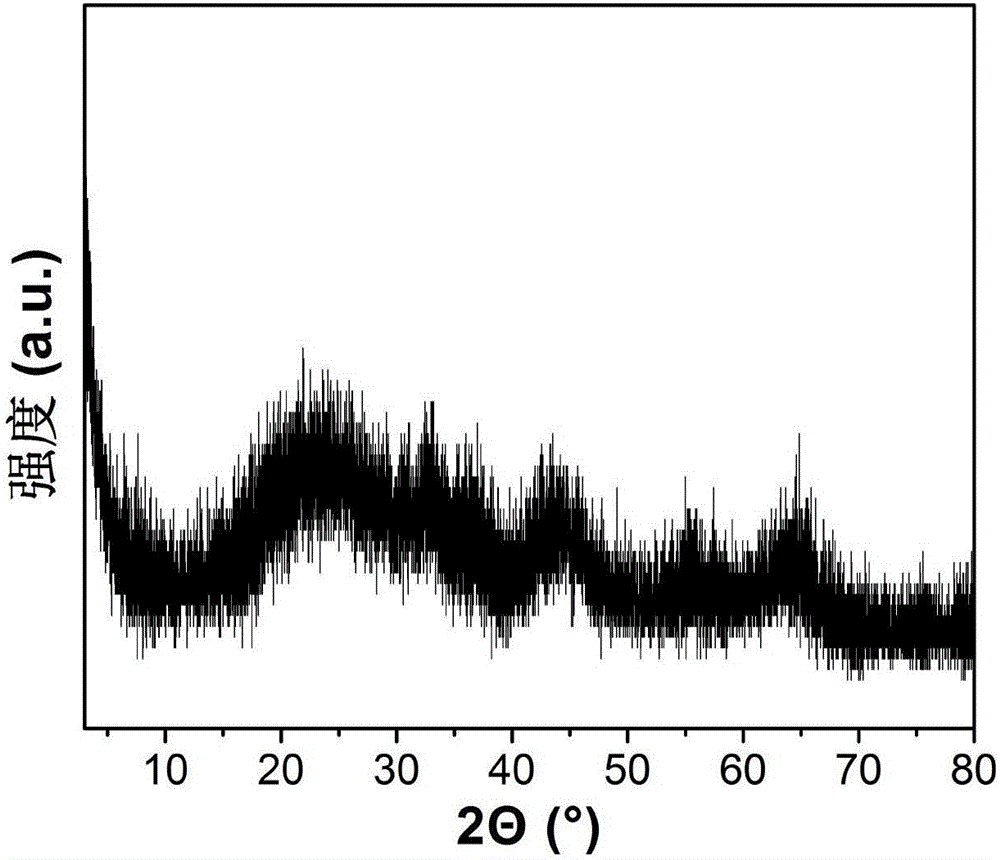

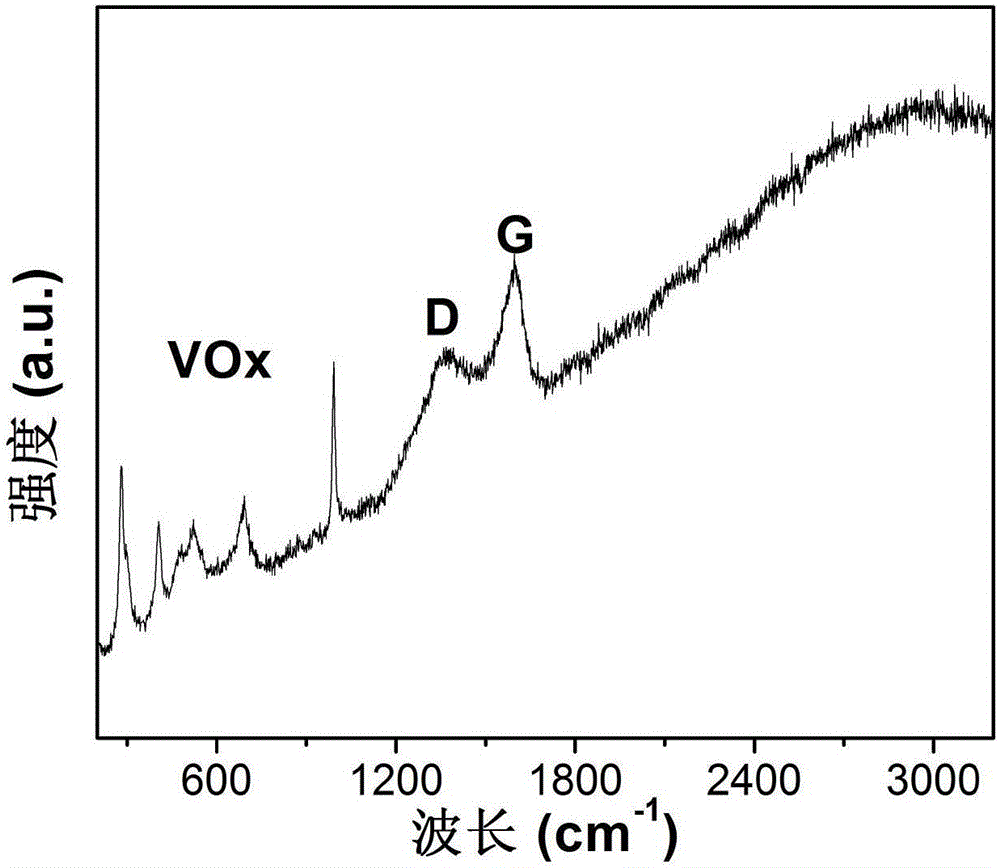

[0041] 3. Under the protection of an inert gas, place the precursor obtained in step 2 in a tube furnace, rai...

Embodiment 2

[0051] A new type of catalyst material for the negative electrode material of sodium ion battery, a vanadium carbide / porous carbon nanorod composite formed by high-temperature carbonization of a metal-organic framework complex. The difference between this embodiment and the specific embodiment 1 is: step 3 The constant temperature is 800°C. Other steps and parameter are identical with specific embodiment 1.

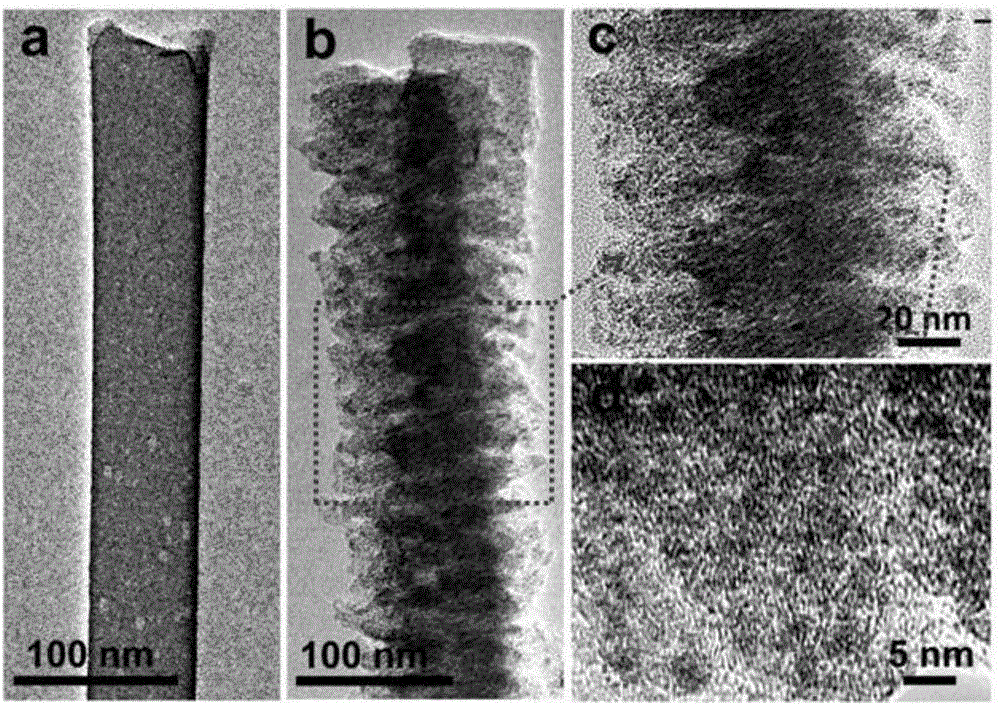

[0052] A morphology test was performed on the vanadium carbide / porous carbon nanorods obtained in Example 2 of the present invention.

[0053] Figure 8 It is the SEM picture of vanadium carbide / porous carbon. It can be seen from the picture that the microscopic appearance of the product is a nanorod with a directional crack pore structure, uniform in size, about 100nm in diameter, and about 500nm in length.

Embodiment 3

[0055] A new catalyst material for the negative electrode material of a sodium ion battery, a cobalt vanadium oxide / porous carbon nanorod composite formed by a metal-organic framework complex through high-temperature carbonization. The difference between this embodiment and the specific embodiment 1 is: the steps One vanadium chloride solution was replaced by the same molar cobalt salt. Other steps and parameter are identical with specific embodiment 1.

[0056] A morphology test was performed on the cobalt vanadium oxide / porous carbon nanorods obtained in Example 3 of the present invention.

[0057] Figure 9 It is the SEM picture of cobalt vanadium oxide / porous carbon. It can be seen from the picture that the microscopic appearance of the product is a nanorod with a cracked pore structure. The diameter is about 500nm and the length is about 1.5μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com