Rectifying device and preparation method thereof

A technology of rectifier devices and devices, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of low forward conduction voltage drop, high blocking voltage, current leakage, and high turn-on voltage of PN junction diodes. Achieve the effect of reducing production cost and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

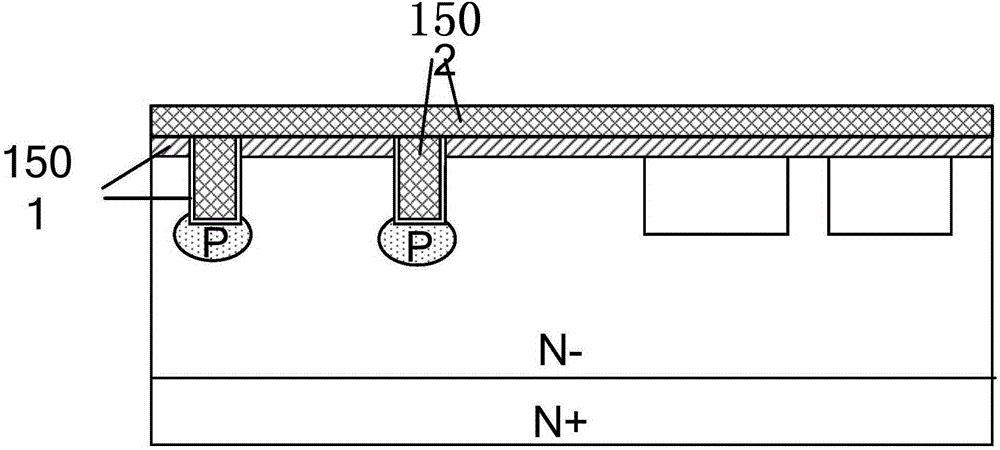

[0054] A rectifier device provided by Embodiment 1 of the present invention, the device includes a substrate of the first conductivity type, a cell region and a terminal region; a groove-shaped region is provided on the front of the substrate of the cell region; There is a second conductivity type buried layer region; the remaining area of the substrate front of the cell region except the trench type region is provided with a second conductivity type body region; the substrate front of the cell region is provided with a first metal electrode; the substrate The back is provided with a second metal electrode.

[0055] Wherein, the terminal region includes a terminal structure, and the terminal structure can specifically be a field-limiting ring, a field-limiting ring plus a field plate, a terminal structure prepared by a junction termination extension (JTE) technology, or a laterally variable doping (VLD) In this embodiment, the terminal structure and the like prepared by the ...

Embodiment 2

[0065] An embodiment of the present invention provides a method for manufacturing a rectifier device. The method includes: forming a termination region on the front surface of a substrate of the first conductivity type, and the remaining region on the front surface of the substrate except the termination region is a cell region; A trench-type region, a buried layer region of the second conductivity type, and a body region of the second conductivity type, wherein the trench-type region is arranged on the substrate front side of the cell region, and the buried layer region of the second conductivity type is arranged on the surface of the trench-type region At the bottom, the body region of the second conductivity type is arranged on the remaining area of the substrate front of the cell region except for the trench type region; the first metal electrode is prepared on the substrate front of the cell region; the second metal electrode is prepared on the back of the substrate meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com