A New Method of Machining High Performance Magnesium Alloy Profiles

A magnesium alloy, high-performance technology, applied in the processing field of high-performance magnesium alloy profiles, can solve the problems of low bar strength, unfavorable secondary plastic processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 A new method for processing high-performance magnesium alloy profiles, comprising the following steps:

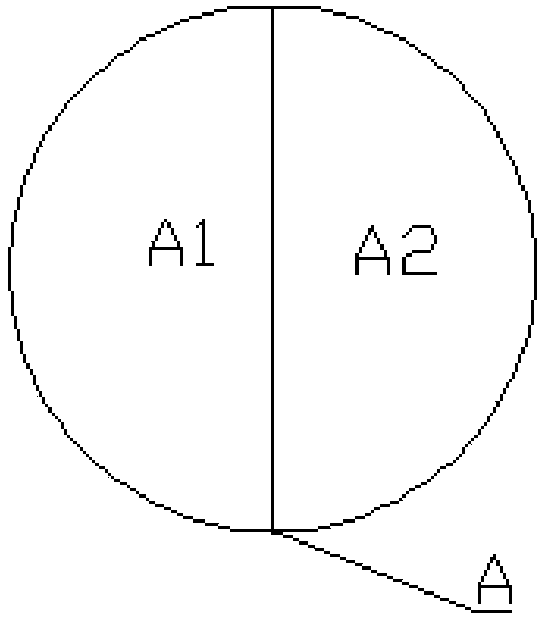

[0020] S1. Select two identical (mass composition and shape are all the same) magnesium alloy ingots A and D, wherein the mass composition of magnesium alloy ingot A is 3.01% Al, 0.80% Zn, 0.40% Mn, 95.79% Mg, magnesium Alloy ingot A is a cylinder with a diameter of 100mm and a length of 100mm, and the magnesium alloy ingot A is cut into semicircular ingots A1 and A2 with a radius of 50mm along the axis (such as figure 1 shown), put semicircular ingots A1, A2 and magnesium alloy ingot D in an industrial resistance furnace, and heat them at 350°C, 200°C and 200°C respectively, and keep them warm for 4h to homogenize deal with;

[0021] S2. Add the magnesium alloy ingot D obtained in step S1 into a 500-ton extruder, and perform plastic processing by rapid hot extrusion process at a temperature of 100°C. The extrusion ratio is 44.4, and the extrusion speed...

Embodiment 2

[0026] Embodiment 2 A new method for processing high-performance magnesium alloy profiles, comprising the following steps:

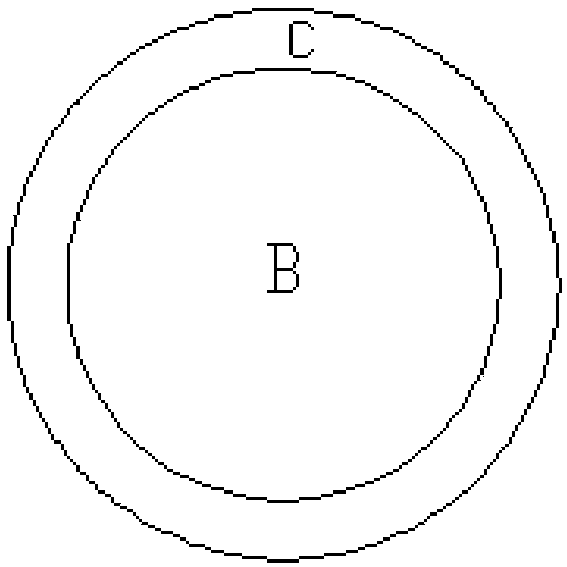

[0027] S1. Select two magnesium alloy ingots B and D with the same mass composition, wherein the mass composition of magnesium alloy ingot B is 3.01% Al, 0.80% Zn, 0.40% Mn, 95.79% Mg, and the diameter of magnesium alloy ingot B is The magnesium alloy ingot D is a cylinder with a diameter of 100 mm and a length of 100 mm, and a magnesium alloy ingot D with a mass composition of 0.42% Si, 0.35% Fe, 0.67% Mg, and 98.50% Al is selected. Aluminum alloy ingot C, aluminum alloy ingot C is a tubular shape with an outer diameter of 100 mm, an inner diameter of 90 mm, and a length of 100 mm. Magnesium alloy ingots B, D and aluminum alloy ingot C are placed in an industrial resistance furnace, and respectively heated at 350°C , 300°C, and 300°C for heating and holding for 3 hours for homogenization treatment;

[0028] S2. Add the magnesium alloy ingot D obtained ...

Embodiment 3

[0033] Embodiment 3 A new method for processing high-performance magnesium alloy profiles, comprising the following steps:

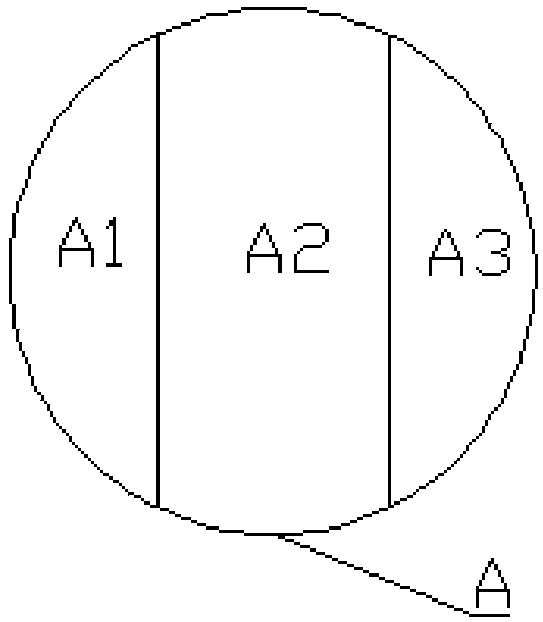

[0034] S1. Select two identical (mass composition and shape are all the same) magnesium alloy ingots A and D, wherein the mass composition of magnesium alloy ingot A is 3.01% Al, 0.80% Zn, 0.40% Mn, 95.79% Mg, magnesium The alloy ingot A is a cylinder with a diameter of 100mm and a length of 100mm, and the magnesium alloy ingot A is cut into billets A1, A2 and A3 along the axis direction (such as figure 2 shown), put billets A1, A2 and A3 and magnesium alloy ingot D in an industrial resistance furnace, and heat them at 250°C, 350°C, 250°C, and 250°C respectively, and keep them warm for 3 hours to carry out uniform treatment;

[0035] S2. Add the magnesium alloy ingot D obtained in step S1 into a 500-ton extruder, and perform plastic processing by rapid hot extrusion process at a temperature of 250° C., with an extrusion ratio of 44.4 and an extrusion s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com