Novel method for preparation and processing of high-performance magnesium alloy profile

A magnesium alloy, high-performance technology, applied in the field of high-performance magnesium alloy profile preparation and processing, can solve the problems of unfavorable secondary plastic processing, low strength of rods, etc., to improve strength, improve formability, and weaken the texture of the base surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 A new method for preparing and processing high-performance magnesium alloy profiles, including the following steps:

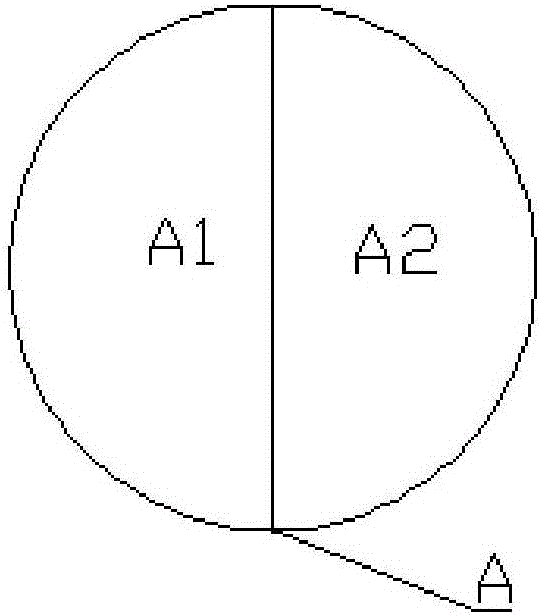

[0022] S1. Select two magnesium alloy ingots A and D with the same mass composition and shape. The mass composition of magnesium alloy ingot A is 3.01% Al, 0.80% Zn, 0.40% Mn, 95.79% Mg, and magnesium The alloy ingot A is a cylindrical shape with a diameter of 100mm and a length of 100mm. Cut the magnesium alloy ingot A along the axis into semicircular ingots A1 and A2 with a radius of 50mm (such as figure 1 Shown), put the semi-circular ingots A1, A2 and magnesium alloy ingot D in an industrial resistance furnace, and heat them at 350℃, 200℃ and 200℃ respectively, and keep them for 4h to homogenize deal with;

[0023] S2. Put the magnesium alloy ingot D obtained in step S1 into a 500-ton extruder, and perform plastic processing in a rapid hot extrusion process at a temperature of 100°C, with an extrusion ratio of 44.4 and an extrusion speed of 45mm...

Embodiment 2

[0028] Example 2 A new method for preparing and processing high-performance magnesium alloy profiles, including the following steps:

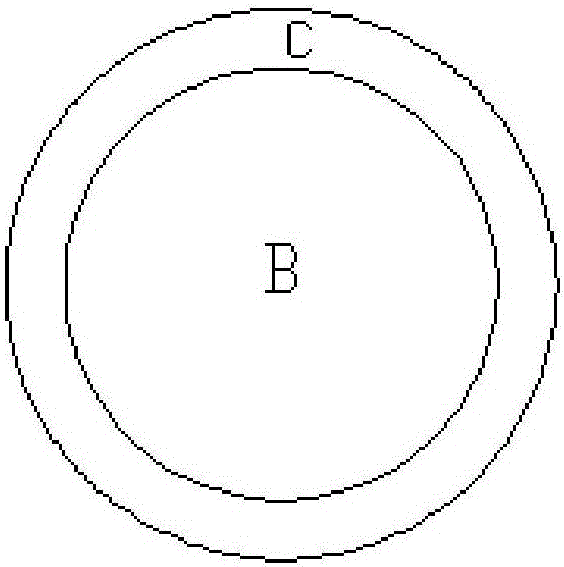

[0029] S1. Select two magnesium alloy ingots B and D with the same mass composition. The mass composition of the magnesium alloy ingot B is 3.01% Al, 0.80% Zn, 0.40% Mn, 95.79% Mg, and the magnesium alloy ingot B is the diameter It is a cylinder with a diameter of 90mm and a length of 100mm. The magnesium alloy ingot D is a cylinder with a diameter of 100mm and a length of 100mm. At the same time, a piece with a mass composition of 0.42% Si, 0.35% Fe, 0.67% Mg and 98.50% Al is selected. Aluminum alloy ingot C, aluminum alloy ingot C is a tube with an outer diameter of 100mm, an inner diameter of 90mm, and a length of 100mm. Place the magnesium alloy ingots B, D and aluminum alloy ingot C in an industrial resistance furnace at 350℃. , Heating at 300℃, 300℃, and keeping it for 3h for homogenization treatment;

[0030] S2. Put the magnesium alloy ingo...

Embodiment 3

[0035] Example 3 A new method for preparing and processing high-performance magnesium alloy profiles, including the following steps:

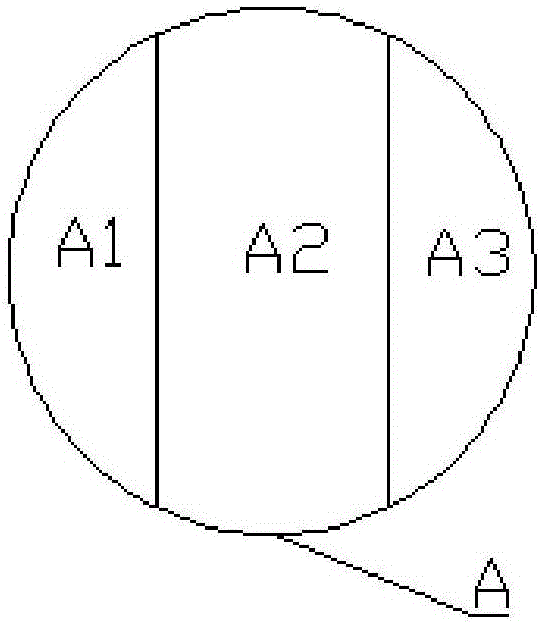

[0036] S1. Select two magnesium alloy ingots A and D with the same mass composition and shape. The mass composition of magnesium alloy ingot A is 3.01% Al, 0.80% Zn, 0.40% Mn, 95.79% Mg, and magnesium The alloy ingot A is a cylindrical shape with a diameter of 100mm and a length of 100mm. The magnesium alloy ingot A is cut into blanks A1, A2, and A3 along the axis (such as figure 2 (Shown), the blanks A1, A2, and A3 and the magnesium alloy ingot D are placed in an industrial resistance furnace and heated at 250℃, 350℃, 250℃, and 250℃ respectively, and kept for 3h for uniformity Chemical treatment

[0037] S2. Put the magnesium alloy ingot D obtained in step S1 into a 500-ton extruder, and perform plastic processing in a rapid hot extrusion process at a temperature of 250°C, with an extrusion ratio of 44.4 and an extrusion speed of 55mm / s, to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com