Cooling method for super-thick material layer sintered ore adopting pre-sintering

A cooling method and a technology of sintering, which are applied in the field of iron and steel metallurgy, can solve the problems of reducing the speed of the machine, limiting the proportion of natural lump ore, and affecting the power generation of ring cooling, so as to reduce the probability of bursting, improve the utilization rate of sensible heat, and improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

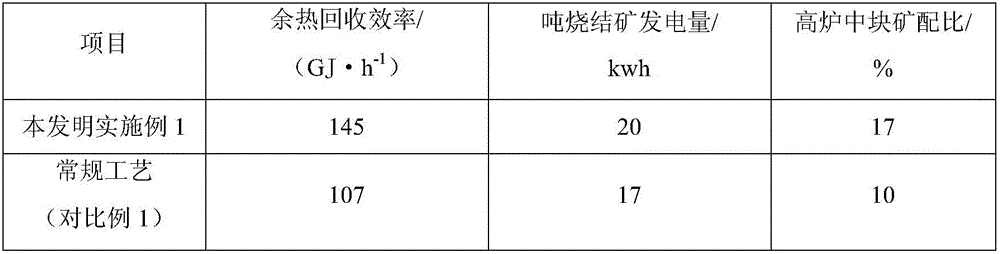

[0016] When the belt roasting machine is used for the pre-sintering process, the thickness of the first cloth layer is 650mm, the thickness of the second cloth firing is 250mm, the total thickness of the material layer is 900mm, and the pre-sintering time is 10min. It is installed at the tail of the belt roaster. There is a sinter separation device, which separates the sinter at the unloading place into sinter with a red fire layer and the remaining low-temperature sinter. The low-temperature sinter enters the ring cooler for cooling, and the high-temperature sinter can directly enter the blast furnace. The natural lump ore (with a particle size of 10-50mm) enters the vertical cooling furnace together for cooling. After the cooled sinter and natural lump ore are screened, the particle size ≥ 5mm directly enters the blast furnace for smelting, and the particle size < 5mm returns to the sintering batching. The production results are compared with Table 1.

[0017] Table 1 Compar...

Embodiment 2

[0021] When the belt roaster is used for the pre-sintering process, the thickness of the first cloth layer is 700mm, the thickness of the second cloth layer is 300mm, the total thickness of the material layer is 1000mm, the pre-sintering time is 20min, and it is installed at the tail of the belt roaster. There is a sinter separation device, which separates the sinter at the unloading place into sinter with a red fire layer and the remaining low-temperature sinter. The low-temperature sinter enters the ring cooler for cooling, and the high-temperature sinter can directly enter the blast furnace. The natural lump ore (with a particle size of 10-50mm) enters the vertical cooling furnace together for cooling. After the cooled sinter and natural lump ore are screened, the particle size ≥ 5mm directly enters the blast furnace for smelting, and the particle size < 5mm returns to the sintering batching. The production results are compared in Table 2.

[0022] Table 2 Comparison of pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com