Process for realizing sorbitizing cold rolling of high-strength and high-fatigue spring narrow band steel

A high-strength and fatigue-resistant technology, applied in the field of metallurgy, can solve the problems of inability to achieve strength and durability, and achieve the effect of excellent cold workability, high strength, and performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A sorbite cold-rolling process for realizing high-strength and high-fatigue spring narrow-strip steel, specifically as follows:

[0020] Raw material selection: choose high carbon steel SK5, thickness 2.5mm, do not use alloy spring steel.

[0021] Process design: The process route is as follows:

[0022] Decoiling and peeling—pickling—levelling—coiling—first stage cold rolling—austempering—second stage cold rolling—slitting—packaging.

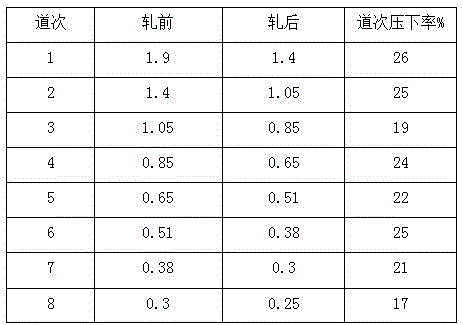

[0023] Process parameter setting: the thickness of the temper mill outlet is set to 2.3mm, the thickness of the first stage cold rolling is 1.9mm, the isothermal quenching adopts a lead bath, the temperature of the lead bath is 790°C, the temperature of the lead bath is 420°C, and the belt running speed is 2.0m / min, water cooling after leaving the lead bath, it is required that the structure of the lead bath is sorbite. The second stage of cold rolling is divided into three rolling passes to reach a finished product thickness of 0.25mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com