Anti-wear energy-saving type diesel engine oil composition

An oil composition and a technology for a diesel engine, applied in the field of lubricating oil, can solve the problems of increasing fuel consumption, increasing fuel consumption, and increasing frictional resistance without considering the decline of fuel economy, so as to ensure fuel economy and its retention. , Improve fuel economy, ensure the effect of lubrication protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

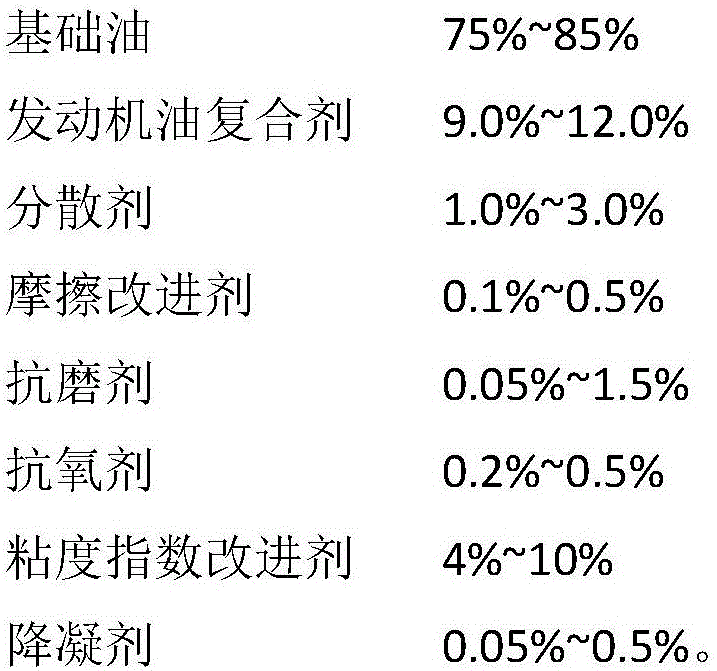

[0030] The following components are blended into anti-wear and energy-saving diesel engine oil CI-4 10W-30 according to mass percentage:

[0031]

[0032]

Embodiment 2

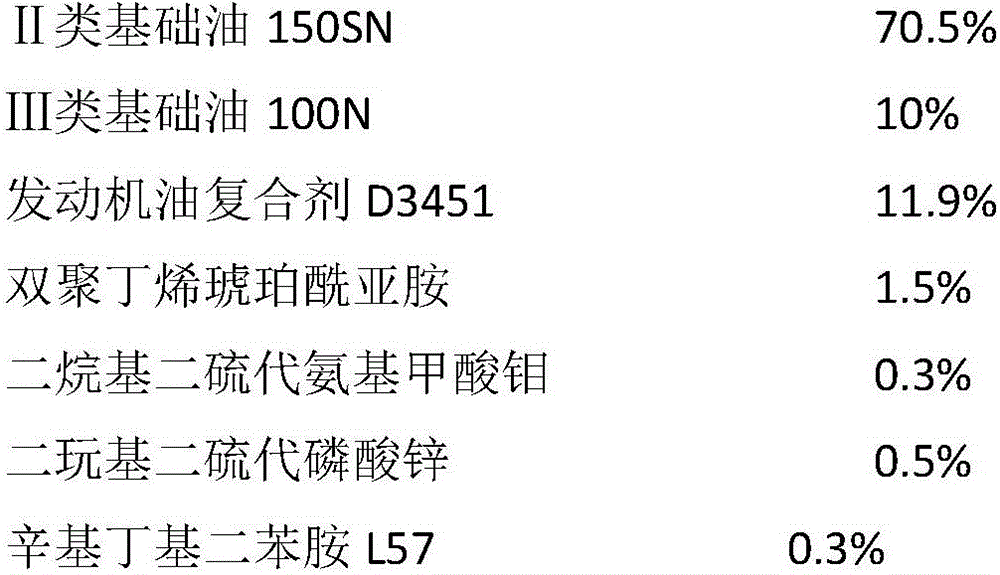

[0034]Anti-wear and energy-saving diesel engine oil CI-4 15W-40 made by blending the following components according to mass percentage:

[0035]

Embodiment 3

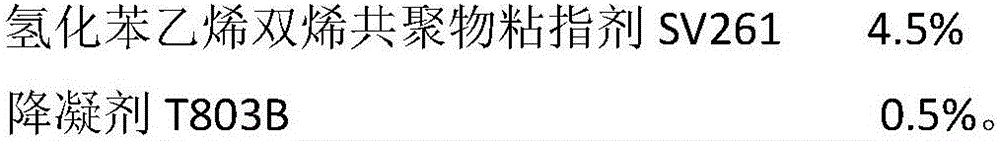

[0037] The following components are blended into anti-wear and energy-saving diesel engine oil CI-4 10W-30 according to mass percentage:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com