Inorganic fireproof sheets and production method therefor

A technology of inorganic fireproof board and inorganic mineral powder, which is applied in the field of home building materials, can solve problems such as complex manufacturing process, deformation and strength reduction, corrosion of steel components, and short fire resistance time limit, and achieve simple and fast manufacturing process, excellent mechanical properties, excellent The effect of acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment:

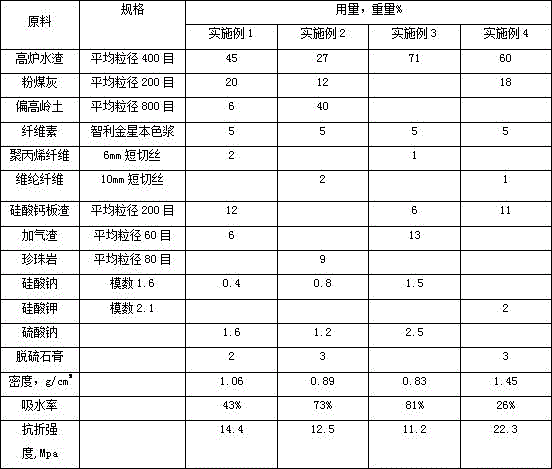

[0016] Examples The composition and test results of the inorganic fireproof boards prepared in the examples are given in Table 1.

[0017] Prepare the inorganic fireproof board with the following steps:

[0018] 1) Mixing: Measure the raw materials, fully dissolve the cement in water, mix evenly with water in a high-speed mixer, and control the mass concentration of the slurry to 18%.

[0019] 2) Board making: The mixed slurry is dehydrated to a certain thickness of the slab through the commonly used method of drawing, flow or molding for the manufacture of fiber cement boards.

[0020] 3) Curing: Curing in a curing room for 4-48 hours at 20-80°C.

[0021] 4) Drying: Dry the cured slabs with a dryer until the water content is less than 10%, and then sand them and cut them into inorganic fireproof boards of required size.

[0022] 5) Testing: test the flexural strength, density and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com