An ultra-high performance cement-based composite material based on cellulose fiber internal curing and its preparation method

A cellulose fiber, ultra-high-performance technology, applied in the field of building materials or basic engineering construction, to achieve improved flexural strength, enhanced waterproof performance and durability, and easy-to-obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

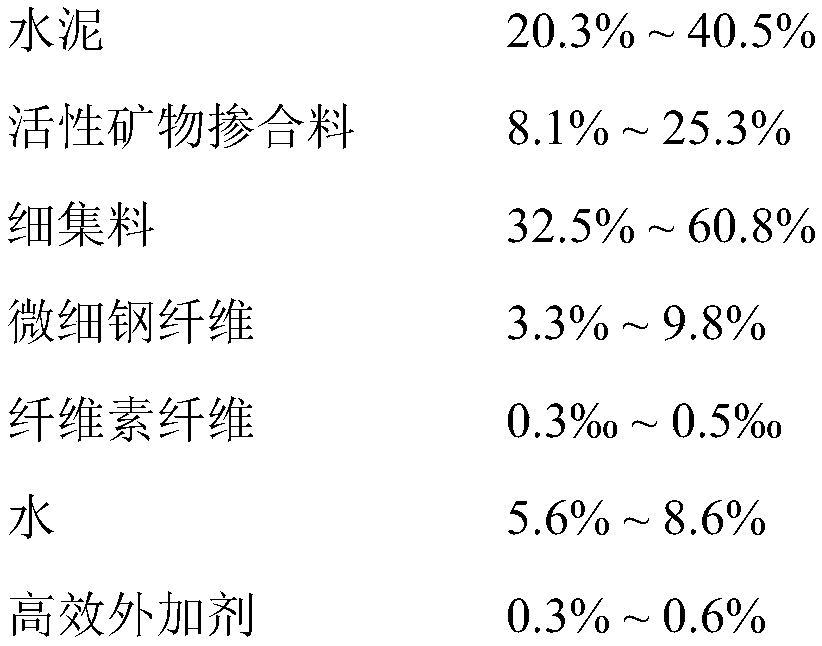

[0034] The preparation method of the above-mentioned ultra-high-performance cement-based composite material based on cellulose fiber internal maintenance comprises the following steps:

[0035] (1) Add water, fine aggregate and cellulose fiber into the mixer at a speed of 110-130 rpm, and stir for 20-35 minutes;

[0036] (2) Add cement, active mineral admixture, and high-efficiency admixture to the mixer in turn, at a speed of 55-65 rpm, and stir for 3-5 minutes until a slurry is formed;

[0037] (3) Slowly add fine steel fibers into the slurry, stir for 2 to 3 minutes at a rotation speed of 55 to 65 rpm, and then stir for 1 to 2 minutes at a rotation speed of 110 to 130 rpm;

[0038] (4) Pour the mortar into the forming mold, vibrate for 60-100 times, remove the mold after standing for 24 hours, and maintain it to obtain the ultra-high performance cement-based composite material.

Embodiment 1

[0041]

[0042]

[0043] Among them, the cement is P·I 52.5 Portland cement; mineral admixtures include F-class fly ash 13.1%, silica fume 4.3% and light calcium powder 4.3%; River sand, continuous gradation, fineness modulus 2.6; fine steel fiber diameter 0.2mm, length 13mm, ultimate tensile strength 2850MPa; cellulose fiber monofilament diameter 18μm, average length 2.1mm, ultimate tensile strength 800MPa; The water reducing agent is a polycarboxylate water reducing agent with a water reducing rate of 40%.

[0044] The performance of the ultra-high-performance cement-based composite material prepared by the above-mentioned components according to the aforementioned process after 28 days of standard curing is as follows:

[0045] Flexural strength 47.8MPa, compressive strength 125.5MPa, self-shrinkage strain 148.9×10 -6 .

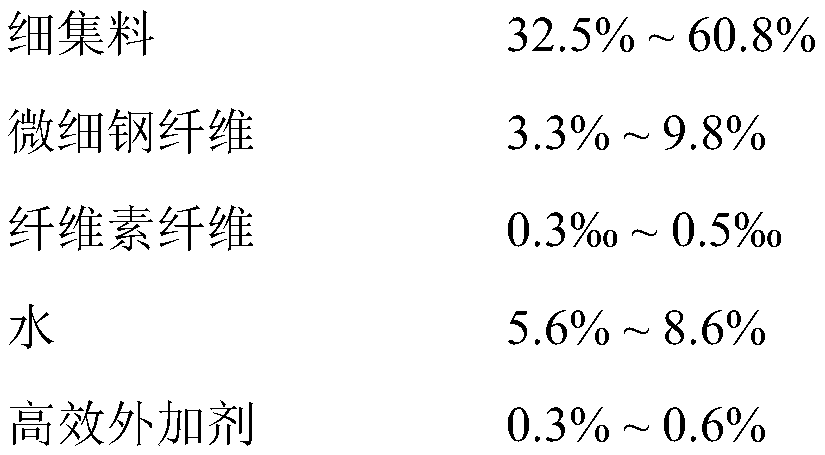

Embodiment 2

[0047]

[0048] Among them, the cement is P·I 52.5 Portland cement; mineral admixtures include metakaolin 12.0%, rice husk ash 4.0%; fine aggregate is ordinary river sand with a maximum particle size of 2.50 mm, continuous gradation, Modulus 2.4; fine steel fiber diameter 0.25mm, length 12mm, ultimate tensile strength 2380MPa; cellulose fiber monofilament diameter 10μm, average length 1.8mm, ultimate tensile strength 900MPa; high-efficiency admixture is water reducing rate of 40% Polycarboxylate water reducer.

[0049] The performance of the ultra-high-performance cement-based composite material prepared by the above-mentioned components according to the aforementioned process after 28 days of standard curing is as follows:

[0050] Flexural strength 46.7MPa, compressive strength 128.4MPa, self-shrinkage strain 130×10 -6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com