A new process for treating acid gas containing ammonia, carbonyl sulfide and hydrogen sulfide and recovering sulfur

A sulfur recovery and acid gas technology, applied in the chemical industry, gas treatment, sulfur compounds, etc., can solve problems such as inability to process, low sulfur recovery rate, and failure to meet industrial sulfur standards, and achieve a wide range of applications and sulfur content. Low, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

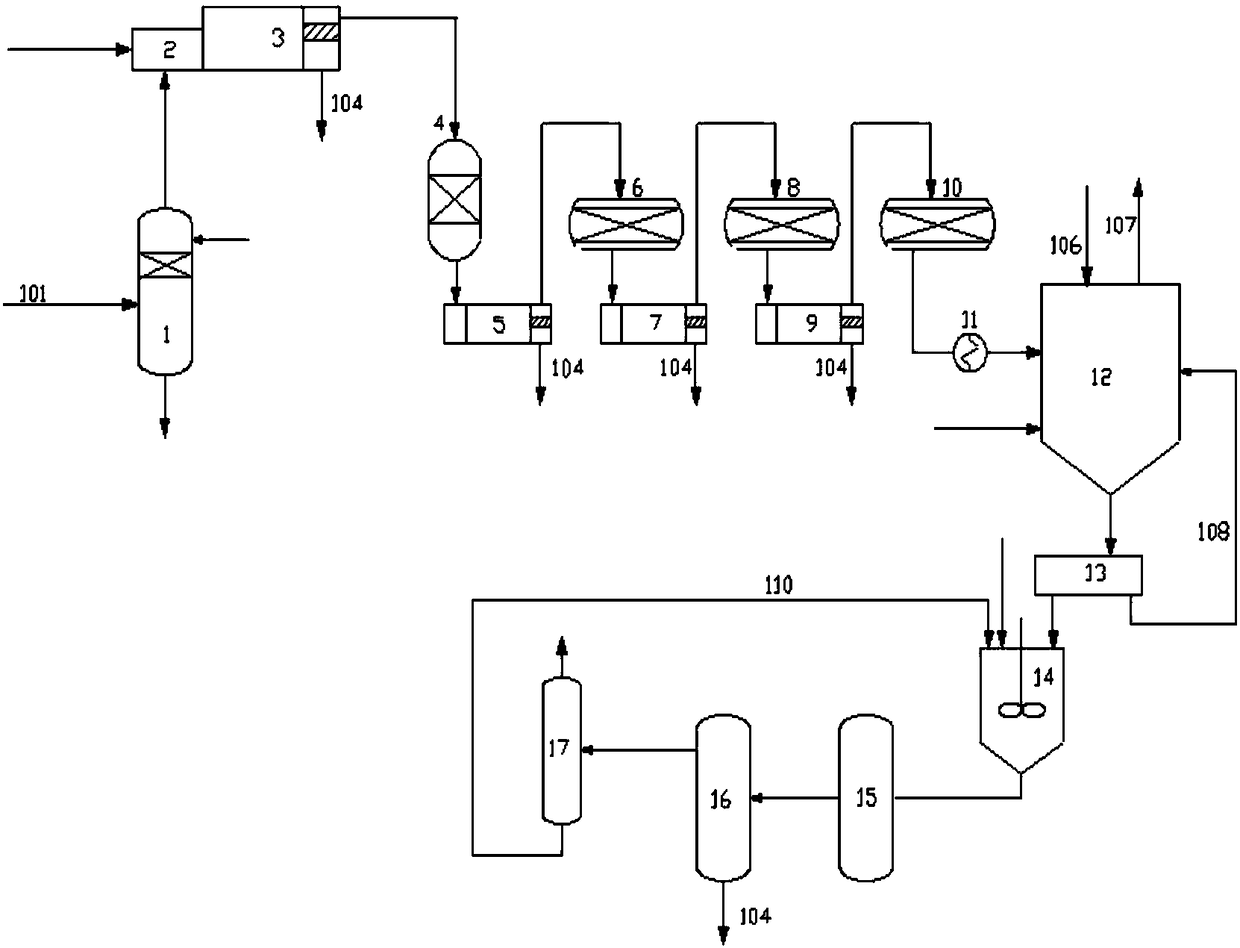

[0029] Such as figure 1 As shown, the acid gas (101) enters the Claus combustion furnace (2) after passing through the water washing tower (1) to remove ammonia, and the reacted process gas enters the waste heat boiler (3) for waste heat recovery, and produces low-pressure steam as a by-product. The recovered process gas enters the hydrolysis reactor (4) after preheating, and the COS and CS generated by the reaction in the Claus furnace are hydrolyzed 2 , the process gas from the hydrolysis reactor passes through the primary sulfur condenser (5), the primary Claus reactor (6), the secondary sulfur condenser (7), the secondary Claus reactor (8), In the third-stage condenser (9), when the liquid sulfur (104) is discharged from the first-stage, second-stage, and third-stage sulfur condensers, low-pressure steam is produced as a by-product. The process gas from the third-stage condenser passes through the hydrogenation reactor (10) after being preheated, and the hydrogenated proc...

Embodiment 2

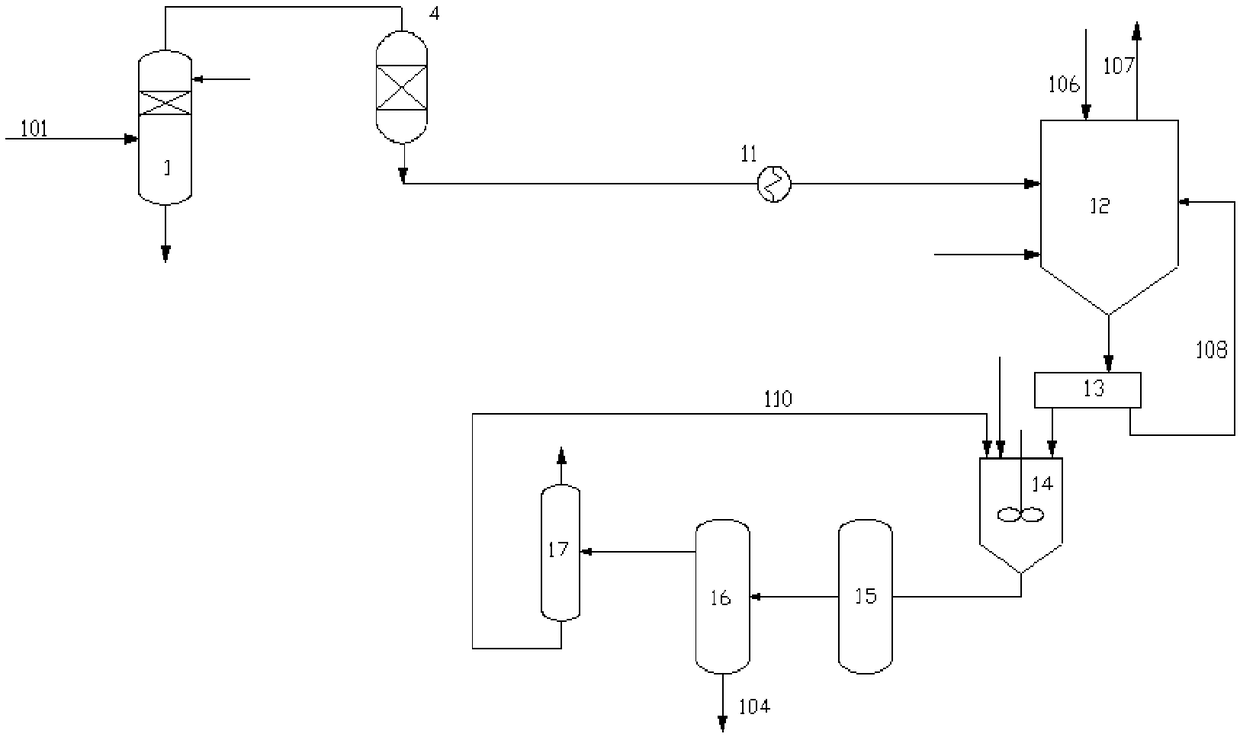

[0031] Such as figure 2 As shown, the acid gas (101) is preheated after being removed from the ammonia by the water washing tower (1), and enters the hydrolysis reactor (4) to hydrolyze the COS contained in the raw acid gas, and the process gas exiting the hydrolysis reactor passes through the process gas cooler (11) enter the absorption oxidation reaction chamber (12) after being cooled to 40~60 ℃, and the H 2 S is converted into elemental sulfur, the complexed iron catalyst is reduced by the air fed in, and the absorbed tail gas (107) is discharged up to the standard. The generated wet sulfur is filtered through the filter (13), the sulfur is sent to the magma tank (14), and the filtrate (108) is returned to the absorption oxidation reaction chamber (12). Sulfur and water form a sulfur slurry in the melt tank and send it to the sulfur melting kettle (15), and after melting, send it to the separator (16) to separate high-purity sulfur (104), and the water layer goes to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com