Limited space continuous hydraulic pushing control system and control method thereof

A control system and limited space technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, lifting devices, etc., can solve the problems of difficult laying of hoisting pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

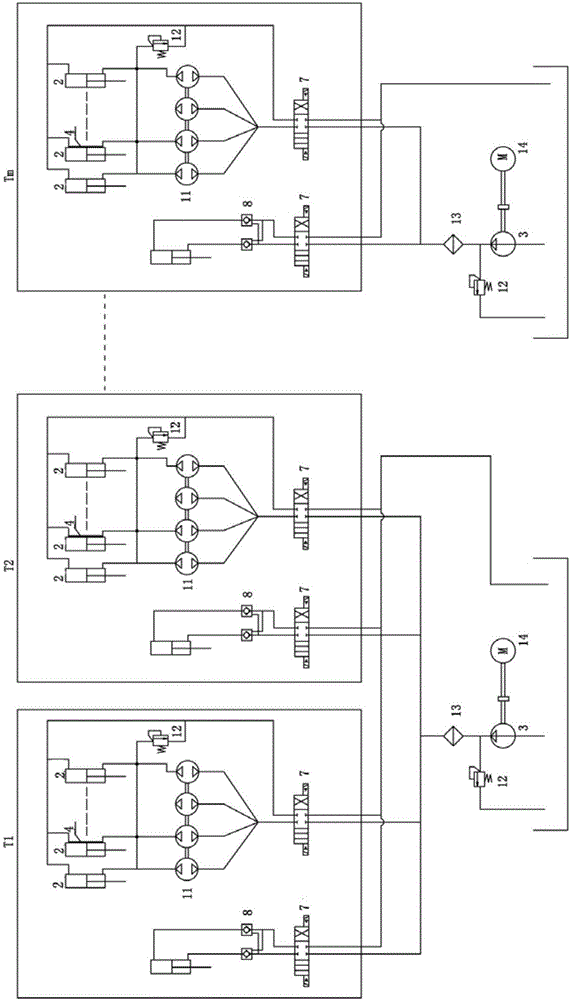

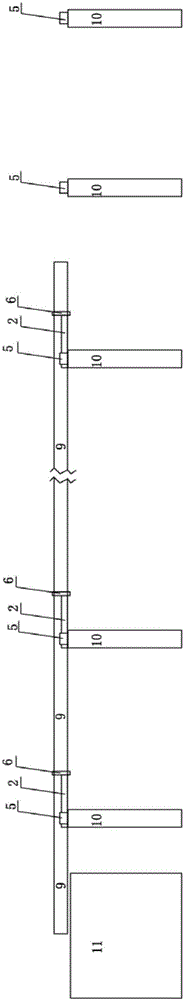

[0037] A continuous hydraulic pushing control system in a limited space, comprising a programmable controller control device 1, a hydraulic pushing device 2, a hydraulic pump 3, a linear displacement sensor 4, a hydraulic clamping device 6, a slider and / or a rolling support 5.

[0038] Wherein, the pushed pipeline 9 is placed on the pipeline assembly and welding platform and the pipeline support 10, and the hydraulic pushing device 2 is fixed on the pipeline support 10 where the pushed pipeline 9 is located or on the support of the auxiliary platform, and along the pushed pipeline 9 One or more are arranged on both sides, and a plurality of them can also be evenly arranged around the center of the push pipe 9 . The hydraulic jacking device 2 is generally installed on a pipeline support or a building platform or other objects, and fixed with a steel structure support, which can be made into separate parts for easy transportation and assembly at the construction site.

[0039] O...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, except that the limited-space continuous hydraulic jacking control system described in this embodiment is composed of multiple sets of control systems arranged in series along the pipeline to be pushed. There are multiple sets of programmable controller control devices 1, and the areas are divided according to the number of programmable controller control devices 1, and the control signals and feedback signals of the corresponding areas are connected to the output and input terminals of the programmable controller control devices 1 in the corresponding areas; and select Among them, one programmable controller control device 1 is the main controller, and the other programmable controller control devices 1 are auxiliary controllers, and the main and auxiliary controllers are connected by field bus. One or more linear displacement sensors 4 are arranged on each hydraulic jacking control system.

[0054] The continuous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com